Overview

The resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing involves the production of a wide range of materials used in various applications. It includes the manufacturing of synthetic resins, such as plastics, synthetic rubber for tires and industrial purposes, and artificial and synthetic fibers and filaments used in textiles, clothing, and other industries. This industry plays a crucial role in supplying materials for everyday products and industrial applications, driving innovation and meeting consumer demand.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as reactor, extruder, mixer, spinneret, filament drawing machine, polymerization vessel, compounding equipment, pelletizer, melt pump, curing oven, calendaring machine, stretching machine, winding machine, cutting machine, spinning beam, filament winding machine, coater, heat exchanger, dryer, filter, centrifuge, autoclave, granulator, chiller, blending unit, vacuum system, distillation column, cooling tower, pulverizer and compression molding machine.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Resin, Synthetic Rubber, and Artificial and Synthetic Fibers and Filaments Manufacturing

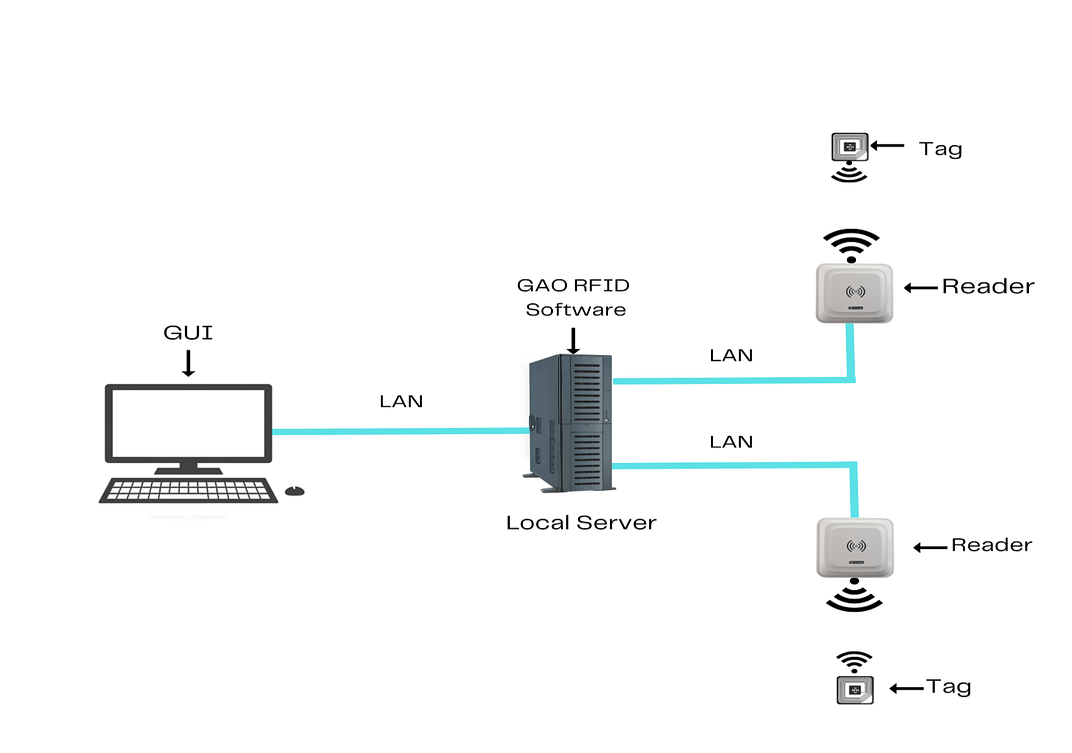

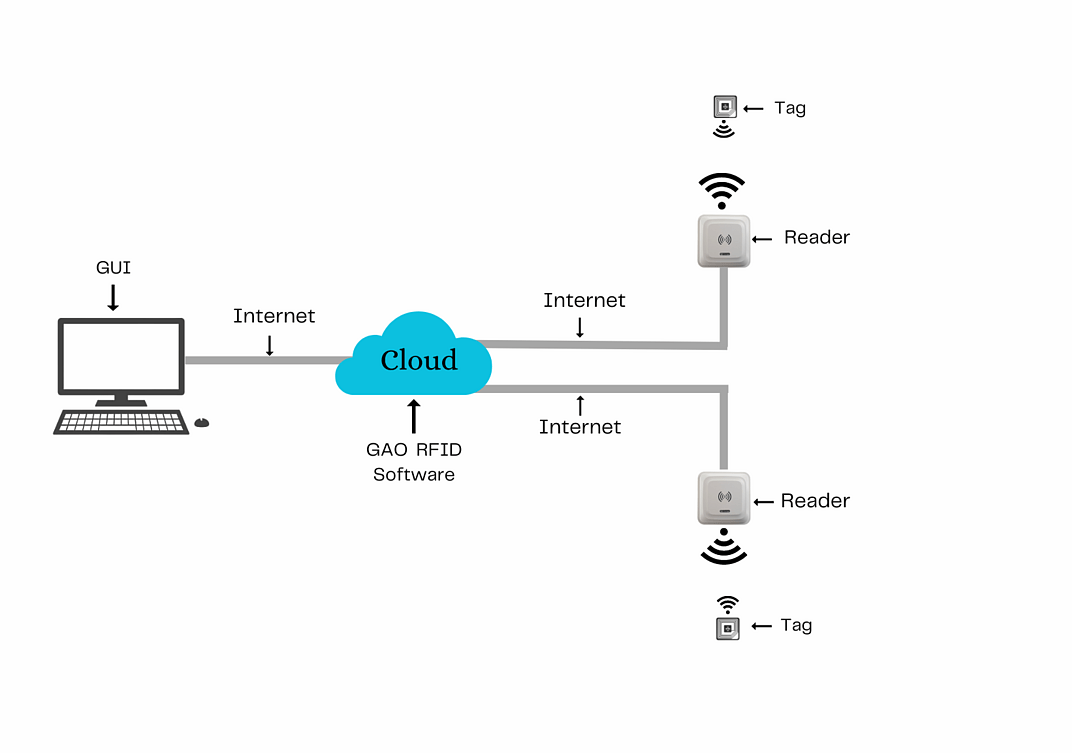

To satisfy its customers, GAO’s RFID or RFID Systems for resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing with its software running on a local server.

GAO’s RFID technologies bring the many benefits to the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry

- Improved Inventory Mangement: GAO RFID can be used to track raw materials, work-in-progress, and finished goods, providing real-time visibility into inventory levels and location. This reduces the risk of stockouts, improves production planning, and helps optimize the use of warehouse space.

- Enhanced Supply Chain Visibility: Our RFID technology can provide end-to-end visibility of the supply chain, enabling better coordination with suppliers and distributors. This can help reduce lead times, minimize disruptions, and improve overall supply chain efficiency.

- Increased Production Efficiency: GAO’s RFID can be used to track production processes, enabling manufacturers to identify bottlenecks, optimize workflows, and reduce waste. This can help increase production efficiency and reduce costs.

- Better Quality Control: RFID can be used to track and trace materials and products throughout the manufacturing process, enabling manufacturers to quickly identify defects and take corrective action. This can help improve product quality and reduce the risk of recalls.

- Improved Asset Management: Our RFID technology can be used to track equipment and machinery, enabling manufacturers to optimize asset utilization, reduce maintenance costs, and extend the lifespan of their assets. This can help reduce downtime, improve productivity, and increase profitability.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger workspaces within the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry

- Real-time Asset Tracking: GAO’s BLE technology can be used to track assets such as raw materials, finished products, and equipment in real-time, enabling manufacturers to quickly locate them and optimize their use. This can improve inventory management, reduce waste, and increase productivity.

- Condition Monitoring: Our BLE technology can be used to monitor the condition of equipment and machinery, providing real-time data on performance, usage, and maintenance needs. This can help manufacturers detect and address issues before they result in downtime or production delays.

- Enhanced Worker Safety: GAO BLE can be used to track workers in hazardous environments and alert them to potential safety risks. This can improve worker safety and reduce the risk of accidents, injuries, and lawsuits.

- Improved Collaboration: Our BLE technology can be used to enable collaboration and communication between workers and teams, improving productivity and efficiency. For example, workers can use BLE-enabled devices to share data and information, collaborate on tasks, and communicate with each other in real-time.

- Increased Automation: GAO’s BLE technology can be used to automate various manufacturing processes, reducing the need for manual intervention and improving efficiency. For example, BLE-enabled sensors can be used to automatically control the temperature, humidity, and other environmental factors in a manufacturing facility, improving product quality and reducing waste.

GAO’s RFID and drone technologies are often combined, and such solutions offer the following benefits to the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry

- Real-time Inventory Tracking: GAO’s RFID technology combined with drones can be used to track inventory in real-time, providing accurate and up-to-date information on the location and status of materials and finished goods. This can help improve inventory management, reduce stockouts, and increase production efficiency.

- Enhanced Security: Our RFID technology can be used to monitor access to sensitive areas of a manufacturing facility, and drones equipped with RFID readers can be used to detect and respond to unauthorized access or security breaches. This can improve facility security and reduce the risk of theft or damage.

- Improved Asset Management: GAO RFID technology combined with drones can be used to track and manage assets such as equipment and machinery, providing real-time data on usage, location, and maintenance needs. This can help optimize asset utilization, reduce maintenance costs, and extend the lifespan of assets.

- Reduced Operational Costs: By using drones equipped with RFID readers to automate inventory tracking, asset management, and security monitoring, GAO’s RFID technology can help manufacturers reduce operational costs and improve efficiency. This can lead to increased profitability and competitiveness in the marketplace.

- Increased Safety: RFID-enabled drones can be used to perform safety inspections of manufacturing facilities, identify potential hazards, and monitor compliance with safety regulations. GAO’s technology can help improve worker safety and reduce the risk of accidents and injuries in the workplace.

Here are benefits of GAO’s IoT technologies to the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry

- Predictive Maintenance: GAO’s IoT technology can be used to monitor equipment and machinery in real-time, providing data on usage, performance, and maintenance needs. This can help manufacturers identify potential issues before they cause downtime or production delays, reducing maintenance costs and improving productivity.

- Increased Efficiency: Our IoT technology can be used to automate various manufacturing processes, such as inventory tracking, asset management, and quality control. This can help manufacturers reduce waste, improve productivity, and increase profitability.

- Improved Supply Chain Management: GAO IoT technology can be used to track raw materials and finished products throughout the supply chain, providing real-time data on location, temperature, and other environmental factors. This can help manufacturers optimize their supply chain, reduce waste, and improve product quality.

- Enhanced Worker Safety: Our IoT-enabled sensors can be used to monitor environmental factors such as temperature, humidity, and air quality, ensuring that workers are not exposed to unsafe conditions. This can help improve worker safety and reduce the risk of accidents, injuries, and lawsuits.

- Advanced Analytics: GAO’s IoT technology can be used to collect and analyze data from various sources, such as sensors, equipment, and machines. This can help manufacturers gain insights into their operations, identify areas for improvement, and make data-driven decisions.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Resin, Synthetic Rubber, and Artificial and Synthetic Fibers and Filaments Manufacturing

GAO RFID Inc. has helped many companies in the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- FCC regulations: The Federal Communications Commission (FCC) sets rules for the use of radio frequency identification (RFID), Bluetooth Low Energy (BLE), and other wireless communication devices to ensure they don’t interfere with other wireless systems.

- FDA regulations: The U.S. Food and Drug Administration (FDA) regulates the use of RFID in pharmaceuticals and medical devices to ensure safety and efficacy.

- Transport Canada regulations: Transport Canada regulates the use of drones and other unmanned aircraft systems (UAS) in the manufacturing industry to ensure safe operation and airspace integration.

- ASTM International: ASTM International develops and publishes voluntary consensus standards for the manufacturing industry, including standards for synthetic rubber and plastics.

- ISO 18000-6C: This international standard defines the air interface protocol for RFID systems operating in the UHF frequency range being relevant to the resin and synthetic materials industry.

- NIST Cybersecurity Framework: The National Institute of Standards and Technology (NIST) provides guidelines and best practices for securing internet of things (IoT) devices and systems.

- UL standards: UL develops and publishes safety standards for a range of products, including plastics, synthetic materials, and electrical devices used in manufacturing.

- OSHA regulations: The Occupational Safety and Health Administration (OSHA) sets regulations for workplace safety, including the use of drones and other machinery in the manufacturing industry.

US Government Regulations

- Clean Air Act: The Clean Air Act is a federal law that regulates air emissions from stationery and mobile sources, including industrial processes and vehicles used in the manufacturing industry.

- Toxic Substances Control Act: The Toxic Substances Control Act (TSCA) gives the Environmental Protection Agency (EPA) authority to regulate the manufacture, importation, and use of chemicals, including those used in the manufacturing of synthetic materials.

- Occupational Safety and Health Act: The Occupational Safety and Health Act (OSHA) sets workplace safety standards and requirements for employers, including those in the manufacturing industry.

- Resource Conservation and Recovery Act: The Resource Conservation and Recovery Act (RCRA) regulates the management of hazardous waste, including waste generated by the manufacturing of synthetic materials.

Canadian Government Regulations

- Canadian Environmental Protection Act: The Canadian Environmental Protection Act (CEPA) is a federal law that regulates the use and disposal of toxic substances, including those used in the manufacturing of synthetic materials.

- Transportation of Dangerous Goods Act: The Transportation of Dangerous Goods Act (TDG) regulates the transportation of hazardous materials, including those used in the manufacturing of synthetic materials.

- Canadian Labour Code: The Canadian Labour Code sets employment standards and regulations for federally regulated workplaces, including those in the manufacturing industry.

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing such as:

Personnel Management

- Employee recruitment and onboarding

- Training and development programs

- Performance management and evaluation

- Employee scheduling and shift management

- Payroll and benefits administration

- Compliance with labor laws and regulations

Equipment Management

- Maintenance and repair tracking

- Equipment inventory management

- Preventive maintenance scheduling

- Equipment calibration and testing

- Asset tracking and utilization

- Equipment performance monitoring

Access Control

- Security systems and surveillance

- Identity verification and authentication

- Access restriction to sensitive areas

- Visitor management and tracking

- Security incident reporting and management

- Compliance with safety regulations

Warehouse Management

- Inventory tracking and management

- Order fulfillment and picking

- Warehouse layout optimization

- Receiving and put-away processes

- Barcode and RFID tracking

- Inventory replenishment and stock rotation

Supply Chain Management

- Demand forecasting and planning

- Supplier relationship management

- Procurement and purchasing

- Order management and tracking

- Transportation and logistics management

- Supply chain visibility and analytics

Other Applications

- Quality control and assurance

- Environmental health and safety management

- Energy management and sustainability

- Production planning and scheduling

- Research and development tracking

- Regulatory compliance management

- Customer relationship management (CRM)

- Sales and marketing analytics

GAO has enabled its customers to make use of some of leading software and cloud services in the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry. Below are some of popular software and cloud services in the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry.

- SAP S/4HANA: A cloud-based enterprise resource planning (ERP) system for managing all aspects of business operations, including personnel management, equipment management, warehouse management, and supply chain management.

- Oracle NetSuite: A cloud-based ERP system for managing all aspects of business operations, including personnel management, equipment management, warehouse management, and supply chain management.

- Microsoft Dynamics 365: A cloud-based ERP system for managing all aspects of business operations, including personnel management, equipment management, warehouse management, and supply chain management.

- Infor CloudSuite Industrial: A cloud-based ERP system for manufacturing industries that includes functionality for personnel management, equipment management, warehouse management, and supply chain management.

- Epicor ERP: A cloud-based ERP system for manufacturing industries that includes functionality for personnel management, equipment management, warehouse management, and supply chain management.

- Workday Human Capital Management: A cloud-based software system for managing personnel and HR functions, including employee data, performance management, and compensation.

- ADP Workforce Now: A cloud-based software system for managing personnel and HR functions, including employee data, payroll, and benefits.

- Zenefits: A cloud-based software system for managing personnel and HR functions, including employee data, benefits, and compliance.

- Netwrix Auditor: A software system for auditing and managing IT infrastructure, including equipment management and access control.

- Fishbowl Warehouse: A software system for managing warehouse operations, including inventory management, order fulfillment, and shipping.

- Procurify: A cloud-based software system for managing procurement processes, including purchase orders, approvals, and supplier management.

- Kronos Workforce Central: A cloud-based software system for managing procurement processes, including sourcing, contracts, and supplier management.

GAO has worked with some of the leading technology companies in resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry:

- Mitsubishi Chemical Holdings Corporation: Mitsubishi Chemical Holdings Corporation is a global chemical company that offers a comprehensive range of materials and technologies. They provide various solutions for the resin, synthetic rubber, and fiber manufacturing industry.

- Intel Corporation: Intel is a leading electronic company known for its computer processors and semiconductor products that are essential for many technological applications in the manufacturing industry.

- IBM (International Business Machines) Corporation: IBM is a renowned information technology company that offers advanced solutions and services for various industries, including data analytics and artificial intelligence applications relevant to the manufacturing sector.

- Teijin Limited: Teijin Limited is a technology-driven company that specializes in advanced fibers, resin products, and synthetic materials. They offer a wide range of innovative solutions catering to the needs of the synthetic materials industry.

- Samsung Electronics: Samsung is a well-known electronic company with a diverse product portfolio, including semiconductors and display technologies, which are crucial components in many manufacturing processes.

- Oracle Corporation: Oracle specializes in developing and marketing database software and technology solutions for businesses, including manufacturing companies that require efficient data management systems.

- Sumitomo Chemical: Sumitomo Chemical Co., Ltd. is a global chemical company that provides a diverse range of products, including synthetic resins, rubber, and specialty materials. Their solutions cater to the needs of the synthetic materials industry.

- Siemens: Siemens is a leading technology company that provides automation, digitalization, and industrial software solutions for manufacturing processes, including those involving synthetic fibers and filaments.

- ABB: ABB is a multinational corporation that specializes in robotics, automation, and power technologies. Their solutions, including advanced control systems and process automation, contribute to optimizing manufacturing operations in the synthetic materials industry.

- Cisco Systems: Cisco is a prominent information technology company that provides networking and communication solutions for businesses, ensuring efficient data transmission and connectivity in manufacturing environments.

- LG Electronics: LG Electronics is a renowned electronic company that manufactures a wide range of products, including displays, lighting solutions, and semiconductors, which are essential components for the manufacturing industry.

- Honeywell International: Honeywell International Incorporated is a diversified technology and manufacturing company that offers advanced solutions for industries such as aerospace, automotive, and chemical, including materials relevant to the synthetic fibers and filaments manufacturing sector.

Case Studies of RFID Applications

Below are some RFID application cases in the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry.

- Dow Chemical implemented RFID technology to improve inventory management and supply chain efficiency. RFID tags were attached to resin containers, allowing real-time tracking and visibility of inventory levels. This led to reduced stockouts, improved production planning, and streamlined logistics operations.

- Shaw Industries, a leading flooring manufacturer, utilized RFID tags embedded in carpet rolls. This enabled automated identification and tracking of individual rolls throughout the production and distribution process. The RFID system improved inventory accuracy, reduced manual labor, and enhanced order fulfillment speed.

- Domtar, a pulp and paper company, deployed RFID technology in their synthetic fiber manufacturing processes. RFID tags were attached to product bundles, enabling real-time inventory management, quality control, and tracking of material flow. This resulted in increased operational efficiency and reduced errors in production and order fulfillment.

- MEGlobal (Canada) implemented UHF RFID technology to enhance their resin production processes. UHF RFID tags were utilized to track and trace raw materials, monitor production stages, and manage inventory levels. The system improved supply chain visibility, optimized production planning, and ensured accurate order fulfillment.

- Lanxess Corporation (U.S.) Lanxess employed UHF RFID tags in their synthetic rubber manufacturing operations. By attaching RFID tags to rubber bales and containers, they achieved real-time asset tracking, improved inventory management, and enhanced production efficiency. The UHF RFID system enabled seamless material flow and reduced manual errors.

- Teijin Limited (U.S.) Teijin, a global chemical and fiber manufacturer, integrated UHF RFID technology into their artificial fiber production processes. UHF RFID tags were used for batch tracking, quality control, and inventory management. The RFID system provided accurate data for process optimization, minimized waste, and facilitated efficient supply chain operations.

GAO RFID Systems & Hardware for the Resin, Synthetic Rubber, and Artificial and Synthetic Fibers and Filaments Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including electric vehicle manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including electric vehicle manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including electric vehicle manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including electric vehicle manufacturing:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including electric vehicle manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- UHF 860-960 MHz RFID Modules – GAO RFID Inc.

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in electric vehicle manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

- Reactors: Large vessels used for chemical reactions to produce resins, synthetic rubber, and fibers by combining raw materials.

- Extruders: Machines that force molten resin or rubber through a die to create continuous filaments or sheets.

- Spinners: Devices that spin liquid polymers into fibers, allowing for the production of synthetic fibers and filaments.

- Autoclaves: High-pressure vessels used to cure or polymerize raw materials under controlled conditions for resin production.

- Mixers: Equipment used to blend and homogenize various ingredients, such as monomers and additives, in the manufacturing process.

- Calenders: Machinery that processes rubber or resin compounds into sheets of desired thickness and width.

- Drying ovens: Used to remove moisture from materials during the manufacturing process, ensuring proper polymerization and curing.

- Filtration systems: Filters that remove impurities and particles from raw materials or process streams to maintain product quality.

- Cooling towers: Devices that remove heat from industrial processes by circulating water, crucial for controlling temperature during polymerization.

- Extrusion lines: Integrated systems comprising extruders, cooling devices, and winders, used for continuous production of synthetic fibers and filaments.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Resin, Synthetic Rubber, and Artificial and Synthetic Fibers and Filaments Manufacturing Extensively

GAO’s products and technologies have helped its customers in the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry to achieve success in sustainability, circular economy, bio-based materials, carbon footprint reduction, recycled fibers, eco-friendly manufacturing, closed-loop systems, fiber innovation, smart textiles, performance fabrics, microfibers, nanotechnology, advanced polymers, additive manufacturing, 3D printing, fiber composites, lightweight materials, antimicrobial fibers, moisture-wicking fabrics, high-strength fibers, flame retardant materials, dye-sublimation printing, colorfastness, breathability, biodegradable fibers, smart coatings, electrospinning, hybrid materials, fiber optics, conductive fibers.

GAO RFID Inc. has served many customers in the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing, including its various divisions such as

- Resin Manufacturing: This division produces synthetic resins, which are widely used in the production of adhesives, coatings, plastics, and other materials.

- Synthetic Rubber Manufacturing: This division produces synthetic rubber, which is used in the production of tires, belts, hoses, and other automotive and industrial products.

- Fiber and Filament Manufacturing: This division produces synthetic fibers and filaments, such as polyester, nylon, and acrylic, which are used in the production of textiles, carpets, and other consumer and industrial products.

- Composite Manufacturing: This division produces composite materials, which are made by combining two or more materials to create a material with improved properties, such as strength, durability, and weight.

- Adhesive and Coating Manufacturing: This division produces adhesives and coatings, which are used in a wide range of applications, including construction, automotive, and industrial manufacturing.

- Plastics Manufacturing: This division produces plastic materials, which are used in a wide range of consumer and industrial products, such as packaging, toys, and medical devices.

Here are some of the leading companies in the resin, synthetic rubber, and artificial and synthetic fibers and filaments manufacturing industry