Overview

A wide variety of seafood products are available in the U.S. marketplace from many different sources. In the U.S., wild fish and shellfish are harvested by commercial fishermen in both near shore and open ocean waters, and in fresh water lakes or rivers. These same methods are used to farm a wide variety of fish and shellfish in other countries around the world which are then imported into the U.S.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the seafood product preparation and packaging industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as Preparation Equipment, Packaging Equipment, Quality Control and Inspection Equipment, Cooking and Processing Equipment, Handling and Conveying Equipment, Sanitation and Hygiene Equipment and various other production and packaging.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for the seafood product preparation and packaging industry.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Seafood Product Preparation and Packaging

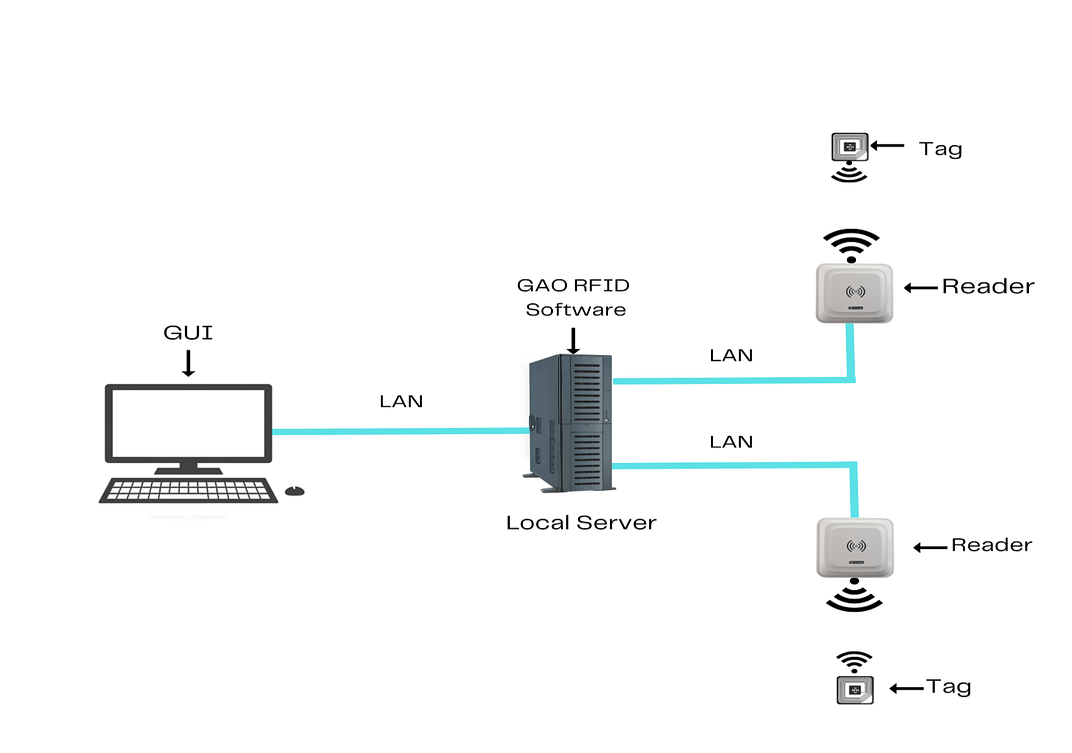

To satisfy its customers, GAO’s RFID or RFID Systems for the seafood product are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for the seafood product industry with its software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for the seafood product are offered in 2 versions. One version is that its software is running on a local server, and another version is that its software runs in the cloud. The above illustrates GAO system for the seafood product industry with its software running on a local server.

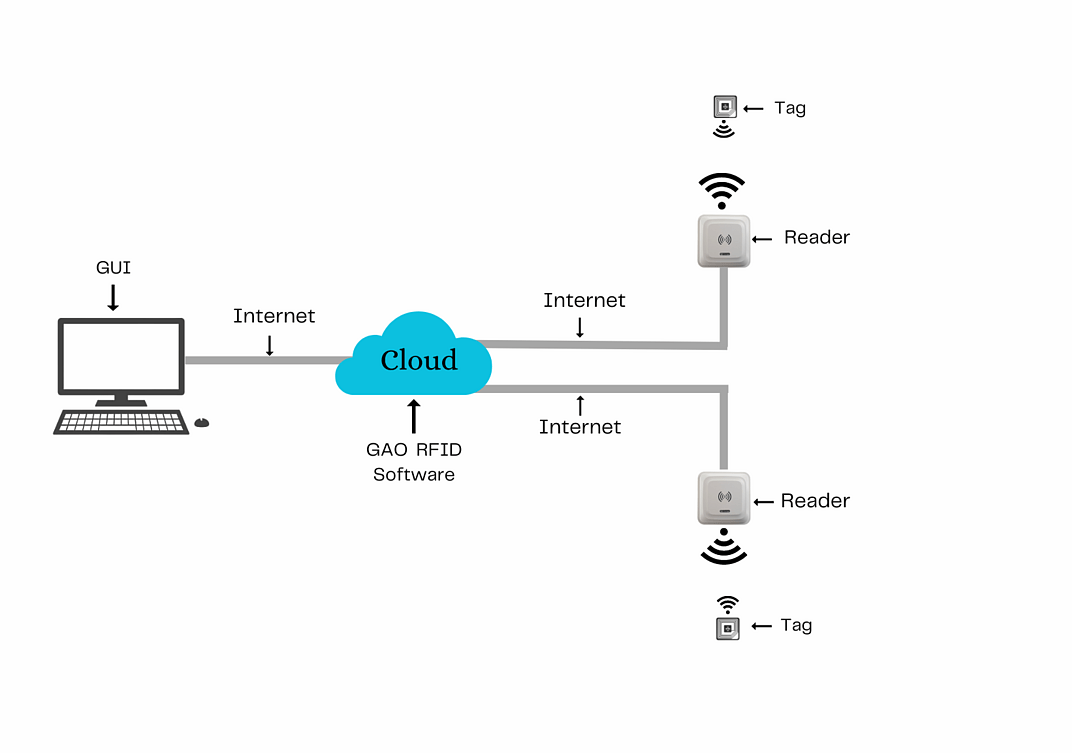

The above illustrates GAO system for the seafood product preparation and packaging industry with its software running in cloud.

The above illustrates GAO system for the seafood product preparation and packaging industry with its software running in cloud.

GAO’s RFID technologies bring many benefits to the seafood product preparation and packaging industry:

- Identification and traceability: Traceability is a concept that we have talked about on our blog on several occasions. It is a very important term to understand how RFID works, so we invite you to read some of our articles to understand it better. The identification of products through GAO’s RFID tags allows us to know where the products are in real time and how much stock we have in total or by series of products. RFID in food helps to identify each and every one of the food products, boxes, trays and general merchandise.

- Automatic inventory and entry control in warehouses: GAO’S RFID helps reduce the labor required for counting and identifying products upon arrival at the warehouse. In addition, it reduces the number of errors and allows inventory management in real time.

- Automatic control and counting of merchandise on conveyors and intralogistics systems: With the Our RFID technology, it is easy to manage the entire flow of logistics operations and detect errors can be done in real time. By installing Our RFID devices adapted to each point of the supply chain, we can quickly and easily identify the pallets and packaging of agric-food products.

- Control of productivity and merchandise in each phase of the process: Radio frequency identification and GAO’s RFID systems, through Our’s RFID tags, allow obtaining a multitude of data in all sectors where RFID solutions can be implemented. RFID in food helps to control the merchandise and guarantees the quality and traceability of the products. By stopping repetitive and routine tasks thanks to RFID, your employees can focus on managing problems that arise during the production process or any task that adds value to the product.

- Control of expeditions and shipments: Distribution centers prepare dispatch and shipments more quickly thanks to the GAO’s RFID solutions. The supply is thus carried out without errors or crossed or duplicate orders, that is to say; with greater accuracy and affecting the benefits and customer satisfaction. In the store or supermarket, once the boxes and pallets arrive, RFID allows again the verification of the identifications of their packages, contrasting the information with the distribution center.

- Recirculation of packaging and control of supplier or customer cycles: In the food industry, plastic boxes and pallets are reused after sale after a disinfection process. Plastic boxes and pallets, being correctly identified with the RFID tag, allow us to carry out a verification process. We can detect mismatches in the number of boxes sent and returned, reducing the number of lost packages.

GAO’s BLE technologies offer longer reading range and particularly attractive for applications with larger work spaces within the seafood product preparation and packaging industry:

- Real-time tracking: GAO’s BLE beacons can be used to track the location and movement of personnel and equipment in real-time, improving safety and productivity.

- Improved communication: Our BLE technology can be used to enable communication between workers and management, allowing for quick and efficient communication in the event of an emergency or other situation.

- Increased efficiency: GAO’s BLE beacons can provide data on the movement and usage of equipment, allowing for more efficient scheduling of maintenance and repairs.

- Better asset management: GAO’s BLE technology can be used to track the location and status of equipment and supplies, helping to prevent loss and reduce the need for manual inventory checks.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to the seafood product preparation and packaging industry:

- Increased efficiency: Drones can quickly scan and identify our RFID tags, providing real-time location information for personnel and assets. This can help operators to better manage their resources and optimize their operations.

- Reduced downtime: By using our RFID tags and drones to monitor equipment and machinery, miners can identify potential problems and perform maintenance or repairs before they become major issues. This can reduce downtime and improve productivity.

- Cost savings: The combination of GAO’s RFID and drones can help seafood product companies reduce costs associated with labour, inventory management, and maintenance. It can also help to improve the accuracy of data collection and reduce the risk of errors.

- Environmental monitoring: Drones equipped with GAO’s RFID technology can be used to monitor environmental conditions in production areas, such as air quality, water levels, and temperature. This can help their employees to comply with environmental regulations and ensure the safety of workers.

Here are benefits of GAO’s IoT technologies to the seafood product preparation and packaging industry:

- Better inventory management: IoT devices can track equipment and inventory in real-time, improving supply chain management and reducing the risk of stock outs or overstocking.

- Remote monitoring: IoT technology allows for remote monitoring of production and packaging operations, enabling managers to access critical data and make informed decisions from anywhere.

- Improved sustainability: IoT devices can monitor and optimize energy consumption, water usage, and waste management, reducing the environmental impact of production and packaging operations.

- Increased automation: IoT technology can be used to automate processes such as transportation, and material handling, reducing labour costs and increasing efficiency.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the seafood products preparation and packaging

GAO RFID Inc. has helped many companies in the seafood products preparation and packaging to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- EPC Gen2 (Electronic Product Code Generation 2): This is one of the most widely adopted RFID standards for supply chain applications, including seafood. EPC Gen2 enables unique identification of individual products and supports efficient data transfer between RFID readers and tags.

- ISO 18000-6C: This standard, also known as UHF Gen2, is part of the ISO/IEC 18000 series and specifies the air interface protocol for RFID systems using UHF (Ultra High Frequency) frequencies. ISO 18000-6C is commonly used in the tracking and tracing of seafood products during processing and packaging.

- GATT (Generic Attribute Profile): GATT is a Bluetooth profile that defines the way BLE devices communicate and exchange data. It enables the establishment of connections and the transfer of information between a BLE-enabled device (such as a Smartphone or sensor) and a seafood-related product or packaging.

- CoAP (Constrained Application Protocol): CoAP is a specialized web transfer protocol designed for resource-constrained devices and networks. It enables efficient communication between IoT devices and seafood-related applications, allowing for the retrieval and update of data over the internet.

- OPC UA (Unified Architecture): OPC UA is a platform-independent machine-to-machine communication protocol for industrial automation and IoT applications. It provides a standardized framework for exchanging data between devices, sensors, and systems involved in seafood processing and packaging, facilitating interoperability.

- FAA Part 107 (United States): Part 107 is a set of regulations established by the Federal Aviation Administration (FAA) in the United States for the commercial operation of small unmanned aircraft systems (UAS), including drones. It outlines requirements for pilot certification, drone registration, operational limitations, and airspace restrictions.

- EASA (European Union): The European Union Aviation Safety Agency (EASA) has developed regulations for drone operations in Europe. These regulations provide guidelines for different categories of drones, including specific requirements for unmanned aircraft used for commercial purpose.

U.S. Government Regulations

- FDA Seafood HACCP (Hazard Analysis and Critical Control Points) Regulations: The Food and Drug Administration (FDA) has established regulations requiring seafood processors to implement HACCP plans. HACCP is a systematic preventive approach to food safety that identifies, evaluates, and controls potential hazards. These regulations ensure that seafood processors follow specific procedures to minimize the risk of contamination and ensure product safety.

- FDA Food Safety Modernization Act (FSMA): The FSMA is a comprehensive food safety legislation that aims to prevent food borne illnesses. It includes various regulations and requirements that impact seafood processing and packaging, such as preventive controls, supplier verification, and product traceability.

- FDA Food Labelling Regulations: The FDA regulates the labelling of seafood products to ensure accurate and informative information for consumers. These regulations cover aspects such as the display of nutrition facts, ingredient declaration, allergen labelling, and country of origin labelling.

- National Marine Fisheries Service (NMFS) Regulations: The NMFS, a division of the National Oceanic and Atmospheric Administration (NOAA), establishes regulations related to the harvesting, processing, and distribution of seafood products. These regulations include catch limits, fishery management plans, and regulations specific to different species of seafood.

Canadian Government Regulations

- Canadian Food Inspection Agency (CFIA) Regulations: The CFIA is responsible for enforcing regulations related to food safety and quality in Canada. They oversee the inspection and regulation of seafood products, including processing facilities, labeling requirements, and import/export controls.

- Safe Food for Canadians Regulations (SFCR): The SFCR is a comprehensive set of regulations introduced by the CFIA to enhance food safety across all sectors, including seafood. It covers various aspects such as preventive controls, traceability, labeling, and licensing requirements for seafood processors and packagers.

- Fish Inspection Regulations: These regulations, administered by the CFIA, establish standards for the inspection, grading, and certification of fish and seafood products. They ensure that fish and seafood products meet specific quality and safety criteria before they are offered for sale.

- Canadian Shellfish Sanitation Program (CSSP): The CSSP, implemented by the CFIA, sets standards and regulations for the safe harvesting and handling of shellfish products. It includes requirements related to water quality monitoring, shellfish harvesting areas, and sanitary controls to prevent shellfish-related illnesses.

ISSC (Interstate Shellfish Sanitation Conference)

ISSC (Interstate Shellfish Sanitation Conference)

EASA (European Union Aviation Safety Agency)

EASA (European Union Aviation Safety Agency)

ASTM (ASTM International)

ASTM (ASTM International)

NMFS (National Marine Fisheries Service)

NMFS (National Marine Fisheries Service)

Food Safety Authority of Ireland (FSAI)

Food Safety Authority of Ireland (FSAI)

Marine Stewardship Council (MSC)

Marine Stewardship Council (MSC)

GS1 (Global Standards One)

GS1 (Global Standards One)

ICAO (International Civil Aviation Organization)

ICAO (International Civil Aviation Organization)

USDA (United States Department of Agriculture)

USDA (United States Department of Agriculture)

Food Standards Australia New Zealand (FSANZ)

Food Standards Australia New Zealand (FSANZ)

OGC (Open Geospatial Consortium)

OGC (Open Geospatial Consortium)

FDA (Food and Drug Administration)

FDA (Food and Drug Administration)

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in the seafood product preparation and packaging industry such as:

Personnel Management:

- Employee scheduling and shift management systems

- Time and attendance tracking solutions

- Training and certification management platforms

- Performance evaluation and workforce management software

Equipment Management:

- Asset tracking and maintenance systems for seafood processing equipment

- Remote monitoring and diagnostics of equipment performance

- Predictive maintenance solutions to optimize equipment uptime and minimize downtime

- Equipment utilization and optimization software

Access Control:

- Electronic access control systems to regulate entry into seafood processing facilities

- Biometric identification and authentication systems

- Visitor management systems to monitor and control access for contractors and guests

Warehouse Management:

- Inventory management systems for tracking and managing seafood products in warehouses

- Real-time stock monitoring and replenishment solutions

- Order fulfillment and picking optimization software

- Warehouse automation and robotics for efficient handling and storage of seafood products

Supply Chain Management:

- Traceability and track-and-trace solutions for seafood products

- Logistics management software for efficient transportation and distribution

- Demand forecasting and planning tools

- Supplier management systems for sourcing and quality control

Other Applications:

- Food safety and compliance management systems

- Quality control and assurance software

- Environmental monitoring and sustainability tracking solutions

- IoT-based sensor networks for monitoring temperature, humidity, and other parameters during transportation and storage

GAO has integrated its RFID, BLE, IoT and drone systems with some of leading software and cloud services in the seafood product preparation and packaging industry. Below are some of popular software and cloud services in the seafood product preparation and packaging industry:

- SAP Success Factors: SAP Success Factors provides a cloud-based human capital management (HCM) suite that includes modules for personnel management, workforce planning, employee self-service, and performance management. It offers comprehensive solutions for managing the entire employee lifecycle.

- Workday HCM: Workday HCM is a cloud-based solution that offers integrated personnel management features, including talent acquisition, on boarding, performance management, and learning management. It provides tools for managing employee data, time tracking, and reporting.

- Oracle Human Capital Management (HCM) Cloud: Oracle HCM Cloud offers a suite of applications for personnel management, talent acquisition, talent management, and workforce rewards. It provides comprehensive features for managing employee information, performance, and development.

- Bamboo HR: Bamboo HR offers a comprehensive human resources software solution that includes features for employee on boarding, time tracking, performance management, and HR reporting. It streamlines personnel management processes and enhances employee engagement.

- ADP Workforce Now: ADP Workforce Now provides a robust suite of HR solutions, including personnel management, payroll processing, benefits administration, and compliance management. It offers features for talent acquisition, employee self-service, and workforce analytics.

- Kronos Workforce Ready: Kronos Workforce Ready is a cloud-based human capital management platform that offers modules for personnel management, time and attendance tracking, workforce scheduling, and HR compliance. It helps streamline HR processes and improve workforce productivity.

- Honeywell Pro-Watch: Honeywell Pro-Watch is an enterprise security management platform that offers comprehensive access control features, including visitor management, badge printing, and alarm monitoring. It helps regulate access to seafood processing facilities and enhances security.

- Seafood Trace: Seafood Trace offers a comprehensive software solution that enables traceability and product tracking throughout the seafood supply chain. It provides real-time information on product origins, quality, and sustainability.

- Food LogiQ: Food LogiQ is a cloud-based platform that helps seafood businesses manage food safety, traceability, and supply chain transparency. It enables tracking and monitoring of seafood products from source to shelf.

- Amazon Web Services (AWS): AWS provides a wide range of cloud services, including computing power, storage, and databases, along with additional tools for analytics, machine learning, and Internet of Things (IoT) integration. It offers scalable and flexible solutions for seafood businesses of all sizes.

- Microsoft Azure: Microsoft Azure offers a comprehensive suite of cloud services, including computing, storage, analytics, and AI capabilities. It provides a secure and scalable platform for seafood businesses to build, deploy, and manage applications.

- Google Cloud Platform (GCP): GCP offers a broad set of cloud services, including compute, storage, and machine learning, as well as data analytics and IoT integration. It provides tools for developing and deploying applications in a scalable and secure environment.

Microsoft Azure

Microsoft Azure

AWS

AWS

FoodLogiQ

FoodLogiQ

Datamine

Datamine

Google Cloud Platform

Google Cloud Platform

Trace Program

Trace Program

Honeywell Pro-Watch

Honeywell Pro-Watch

bambooHR

bambooHR

Kronos

Kronos

IBM Maximo

IBM Maximo

Workday

Workday

Oracle

Oracle

GAO has worked with some of the leading technology companies in the seafood product preparation and packaging industry to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in the seafood product preparation and packaging industry:

- IBM: IBM offers a range of solutions for the seafood industry, including block chain-based traceability, artificial intelligence and analytics, and supply chain optimization. Its solutions enable better tracking of seafood products, improved quality control, and enhanced supply chain efficiency.

- Oracle: Oracle provides a range of cloud-based solutions for the seafood industry, including enterprise resource planning (ERP) software, warehouse management, and supply chain management. Its solutions help seafood businesses improve productivity, reduce costs, and ensure compliance.

- Microsoft: Microsoft offers a range of software and cloud-based solutions for the seafood industry, including productivity tools, data analytics, and Internet of Things (IoT) integration. Its solutions enable better collaboration, data-driven decision-making, and improved product quality.

- SAP: SAP provides a range of solutions for the seafood industry, including ERP software, supply chain management, and analytics. Its solutions enable better traceability, improved inventory management, and streamlined operations.

- Honeywell: Honeywell offers a range of electronic solutions for the seafood industry, including automation and control systems, barcode scanners, and wireless communication devices. Their technologies help streamline processes and improve efficiency.

- Siemens: Siemens provides electronic technology solutions for the seafood industry, including industrial automation systems, data analytics, and remote monitoring solutions. Their technologies enable improved process control and optimization.

- Rockwell Automation: Rockwell Automation specializes in industrial automation and offers electronic technologies such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), and industrial networking solutions. These technologies enhance productivity and efficiency in seafood processing and packaging.

- Aptean: Aptean offers specialized software solutions for the seafood industry, including enterprise resource planning (ERP), warehouse management, and supply chain management. Their systems help streamline operations and improve efficiency.

- JustFoodERP: JustFoodERP is an industry-specific ERP system designed for the seafood and food processing industry. It provides modules for inventory management, production planning, quality control, and compliance tracking.

- Infor: Infor offers a range of enterprise software solutions for the seafood industry, including ERP systems, supply chain management, and asset management. Their systems enable better visibility, traceability, and control throughout the seafood production and packaging processes.

- Fishbowl: Fishbowl provides inventory management and manufacturing software specifically designed for the seafood industry.

Microsoft

Microsoft

Justfood

Justfood

Aptean

Aptean

Schneider Electric

Schneider Electric

Honeywell

Honeywell

SAP

SAP

Rockwell Automation

Rockwell Automation

Oracle

Oracle

Infor

Infor

Fishbowl

Fishbowl

IBM Technology corporation

IBM Technology corporation

SIEMENS

SIEMENS

Case Studies of RFID Applications

Here are cases of applying RFID in the seafood product preparation and packaging industry:

- Bumble Bee Foods (USA): Bumble Bee Foods, a major seafood supplier, implemented an RFID-based solution to improve traceability and reduce errors in their supply chain. They used RFID tags to track and trace seafood products from the point of catch to the processing facilities and throughout the packaging and distribution process. This improved inventory management, reduced waste, and enhanced food safety.

- Clearwater Seafood’s (Canada): Clearwater Seafood’s, a leading seafood company, implemented an RFID system to track and trace their lobster products. RFID tags were attached to lobster crates, enabling real-time visibility into the location and movement of the products. This improved operational efficiency, reduced manual labour, and ensured accurate and timely delivery to customers.

- Pacific Seafood Group (USA): Pacific Seafood Group implemented an RFID-enabled inventory management system to streamline their seafood processing and packaging operations. RFID tags were attached to bins and pallets, allowing automated tracking of inventory throughout the facility. This resulted in improved inventory accuracy, reduced labour costs, and enhanced production efficiency.

- High Liner Foods (Canada): High Liner Foods, a seafood processor and distributor, implemented RFID technology to track and trace their frozen seafood products. RFID tags were applied to individual packages, enabling automated scanning and inventory management. This helped them optimize their supply chain, minimize stock outs, and improve order fulfillment accuracy.

- Seafood Traceability and Authentication: Tracking and authenticating seafood products from harvest to retail using UHF RFID tags. Ensuring product integrity, preventing counterfeiting, and enhancing consumer trust in the supply chain.

- Cold Chain Monitoring and Quality Control: Monitoring and maintaining optimal temperature and environmental conditions during seafood transportation and storage. Using UHF RFID temperature sensors to track and ensure the freshness and quality of seafood products.

- Inventory Management and Stock Control: Automating inventory management processes using UHF RFID tags and readers. Improving accuracy, speed, and efficiency in tracking and managing seafood inventory, reducing errors and waste.

- Shelf Life Management: Monitoring the shelf life of seafood products through UHF RFID-enabled smart labels or tags. Real-time tracking of expiration dates, reducing waste and ensuring product freshness.

- Supply Chain Visibility and Transparency: Improving visibility and transparency across the seafood supply chain through UHF RFID technology. Enhancing traceability, identifying bottlenecks, and optimizing logistics for improved efficiency.

GAO RFID Systems & Hardware for the Seafood Product Preparation and Packaging

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the seafood product preparation and packaging industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the seafood product preparation and packaging industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the seafood product preparation and packaging industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the seafood product preparation and packaging industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the seafood product preparation and packaging industry:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the seafood product preparation and packaging industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the seafood product preparation and packaging industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

- Fish processing machines: These machines are designed for efficient filleting, scaling, skinning, and deboning of fish. They can handle different sizes and species of fish.

- Shrimp peeling machines: These machines automate the process of removing the shells from shrimp. They can handle large volumes of shrimp and reduce manual labor.

- Oyster shucking machines: Oyster shucking machines are used to open oysters quickly and safely. They remove the shells while preserving the oyster meat.

- Seafood grading machines: These machines assess the quality and size of seafood products, such as fish, shrimp, or scallops. They sort the products based on specific criteria, such as weight, length, or color.

- Vacuum packaging machines: Vacuum packaging machines remove air from packaging containers and seal them, extending the shelf life of seafood products. They help prevent spoilage, maintain freshness, and preserve the product’s quality.

- Modified atmosphere packaging (MAP) machines: MAP machines replace the air in the packaging with a specific gas mixture (e.g., nitrogen, carbon dioxide) to create an optimal atmosphere for seafood products. This technique helps prolong shelf life and preserve product quality.

- Freezing equipment: Seafood products often require freezing to maintain freshness. Blast freezers, tunnel freezers, or plate freezers are used to quickly freeze seafood products while minimizing cell damage and maintaining their quality.

- Smokehouses: Smokehouses are used for smoking seafood products, such as salmon or trout. They impart a smoky flavor and enhance the product’s preservation.

- Fish drying equipment: Some seafood products, like dried fish or dried shrimp, require specialized drying equipment. These machines remove moisture from the seafood while preserving its nutritional value.

- Fish meal processing equipment: Fish meal is produced from fish waste and byproducts. Equipment such as cookers, dryers, and grinders are used in the production process to convert the waste into a protein-rich fish meal.

- Fish oil extraction equipment: Fish oil is extracted from fish, primarily from fatty species like salmon or mackerel. Extraction equipment, such as pressers or centrifuges, is used to extract and refine the oil.

- Quality control and testing equipment: This includes devices to measure pH, temperature, salinity, moisture content, and other parameters to ensure product safety and quality compliance.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Seafood Product Preparation and Packaging Extensively

GAO’s products and technologies have helped its customers in the seafood product preparation and packaging industry to achieve success in sustainability, traceability, food safety, clean label, packaging innovation, automation and robotics, IoT (internet of things), blockchain, shelf-life extension, personalization.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in the seafood product preparation and packaging, including many in its various divisions such as

- Seafood Processing: This division involves the processing and transformation of raw seafood into various products. It includes activities such as cleaning, filleting, portioning, freezing, canning, and value-added processing (e.g., marinating, smoking, or packaging seafood products with added ingredients).

- Packaging and Labeling: This division focuses on the packaging and labeling of seafood products to ensure their quality, safety, and marketability. It includes selecting appropriate packaging materials, designing labels with required information (such as product name, origin, ingredients, and expiration date), and implementing proper labeling and bar-coding practices.

- Quality Control and Assurance: This division is responsible for maintaining the quality and safety standards of seafood products. It involves implementing quality control procedures, conducting inspections and tests, ensuring compliance with regulatory requirements, and addressing any product-related issues.

- Cold Chain Management: This division focuses on maintaining the cold chain integrity throughout the seafood supply chain. It includes proper storage, transportation, and handling of seafood products at controlled temperatures to prevent spoilage, maintain freshness, and ensure food safety.

- Distribution and Logistics: This division involves the efficient management of the distribution and logistics processes for seafood products. It includes activities such as order fulfillment, inventory management, transportation planning, warehousing, and delivery to retailers, wholesalers, or end consumers.

- Marketing and Sales: This division is responsible for promoting and selling seafood products to customers. It involves developing marketing strategies, conducting market research, managing branding and packaging design, establishing distribution channels, and building relationships with customers and retailers.

- Regulatory Compliance: This division focuses on ensuring compliance with local, national, and international regulations governing the seafood industry. It includes understanding and adhering to food safety standards, labeling requirements, traceability regulations, and environmental sustainability guidelines.

Here are some of the leading companies in the seafood product preparation and packaging industry:

Aqua Star

Aqua Star

Cooke Aquaculture

Cooke Aquaculture

High Liner Foods

High Liner Foods

The Fishin’ Company

The Fishin’ Company

Clearwater Seafoods

Clearwater Seafoods

Thai Union Group

Thai Union Group

Chicken of the Sea

Chicken of the Sea

Tampa Maid Foods

Tampa Maid Foods

King & Prince Seafood

King & Prince Seafood

Trident Seafoods

Trident Seafoods

Gorton’s Seafood

Gorton’s Seafood

Great American Seafood Import

Great American Seafood Import

Pacific Seafood

Pacific Seafood

Bumble Bee Seafoods

Bumble Bee Seafoods

Red Lobster

Red Lobster

Albion Fisheries

Albion Fisheries

Atlantic Aqua Farms

Atlantic Aqua Farms

Ocean Choice International

Ocean Choice International

Clearwater Seafood’s

Clearwater Seafood’s

Phillips Foods

Phillips Foods

SeaPak Shrimp & Seafood Co

SeaPak Shrimp & Seafood Co

Fishpeople Seafood

Fishpeople Seafood

Harbar Seafood

Harbar Seafood

Cooke Aquaculture

Cooke Aquaculture