Index

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Support Activities for Mining

GAO Helps Customers Comply with Standards, Mandates & Regulations of Support Activities for Mining

GAO Software Provides Easy Integration with API

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for Support Activities for Mining

Overview

Support activities for the mining industry encompass a range of essential functions that provide vital support to mining operations, ensuring their efficiency, safety, and compliance with regulations. These activities are often categorized into two main groups: exploration and extraction support, and mine infrastructure support.

In the first category, exploration and extraction support, activities involve geological surveying, mineral prospecting, and resource evaluation. Geologists and geophysicists conduct surveys to identify potential mining sites, assess the quality and quantity of mineral resources, and determine the feasibility of mining operations. This phase also includes drilling, sampling, and data analysis to pinpoint the precise location and depth of valuable deposits. Additionally, environmental impact assessments and permitting processes are part of this category to ensure that mining operations adhere to environmental regulations and minimize their ecological footprint.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in support activities for mining industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as seismic and electromagnetic survey instruments, drilling rigs and core sampling equipment, GIS (Geographic Information System) software for data analysis, safety equipment such as helmets, respirators, and protective clothing for workers, heavy machinery such as bulldozers, excavators, and haul trucks for excavation and transportation, crushers and processing machinery for mineral refinement, as well as communication and monitoring systems to ensure worker safety and efficient coordination.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for support activities for mining. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Support Activities for Mining

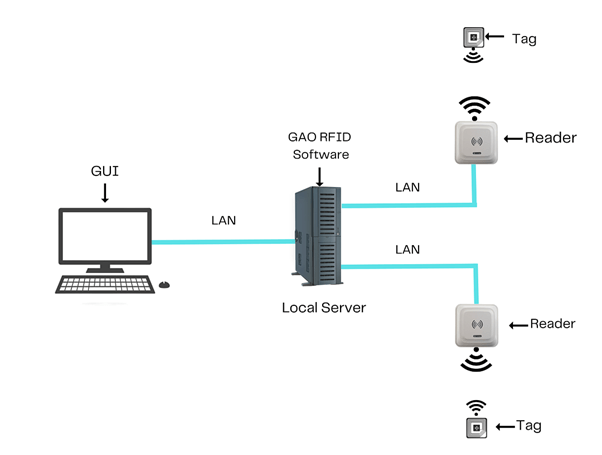

To satisfy its customers, GAO’s RFID or RFID Systems for support activities for mining are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for sub-industry support activities for mining software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for support activities for mining are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for sub-industry support activities for mining software running on a local server.

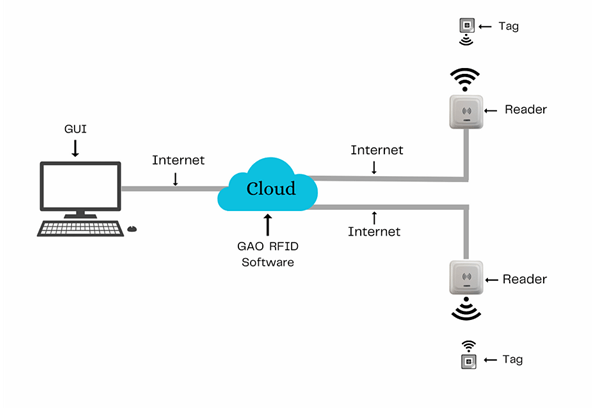

The above illustrates GAO system for support activities for mining with its software running in cloud.

The above illustrates GAO system for support activities for mining with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in support activities for mining industry:

- Asset Tracking: GAO’s RFID tags can be attached to equipment, machinery, and tools, enabling real-time tracking and monitoring of their location and usage. This helps in optimizing equipment utilization, reducing downtime, and preventing theft or loss.

- Inventory Management: GAO’s RFID tags on supplies, spare parts, and consumables allow for accurate inventory tracking, automated reordering, and minimizing stockouts or overstock situations, thus improving overall operational efficiency.

- Personnel Tracking and Safety: GAO’s RFID badges or wearables for workers enhance safety by tracking their movements within the mine. In emergency situations, it aids in locating and evacuating personnel quickly.

- Vehicle and Fleet Management: GAO’s RFID tags on vehicles and trucks enable efficient management of the mining fleet, monitoring fuel usage, maintenance schedules, and ensuring compliance with safety regulations.

- Material Tracking: GAO’s RFID can be used to monitor the movement and quality of materials through the mining and processing stages, helping to ensure that the right materials are processed and that waste is minimized.

- Access Control: RFID access cards or biometric RFID systems can control entry to restricted areas within the mining site, enhancing security and preventing unauthorized access.

- Environmental Monitoring: GAO’s RFID sensors can be used to monitor environmental conditions, such as water quality, air quality, and soil conditions, providing real-time data to ensure compliance with environmental regulations.

- Supply Chain Visibility: GAO’s RFID technology can be used to track the movement of raw materials and finished products throughout the supply chain, ensuring timely deliveries and reducing the risk of theft or tampering.

- Maintenance and Repairs: GAO’s RFID can be used to track maintenance history, schedules, and component replacements for equipment and machinery, facilitating predictive maintenance and reducing downtime.

- Safety Compliance: GAO’s RFID can be used to monitor compliance with safety protocols, ensuring that workers are using the correct safety equipment and following established safety procedures.

- Explosives Management: GAO’s RFID can help manage the inventory and usage of explosives in mining operations, ensuring strict regulatory compliance and safety.

- Environmental Remediation: In post-mining reclamation and remediation efforts, GAO’s RFID can be used to track and manage the planting of native species and monitor the recovery of the ecosystem.

GAO’s drone technologies find the following applications in the support activities for mining industry:

- Surveying and Mapping: GAO’s Drones equipped with high-resolution cameras and LiDAR (Light Detection and Ranging) sensors can quickly and accurately survey large mining sites, creating detailed topographic maps and 3D models for exploration and planning.

- Exploration and Prospecting: GAO’s Drones can be used for aerial reconnaissance to identify potential mining sites, assess geological formations, and locate mineral deposits, saving time and resources during the exploration phase.

- Stockpile Measurement: GAO’s Drones equipped with LiDAR or photogrammetry technology can measure stockpiles of raw materials like ore, coal, or minerals with high accuracy, facilitating inventory management.

- Environmental Monitoring: GAO’s Drones can monitor the environmental impact of mining activities by collecting data on air and water quality, noise levels, and vegetation health, aiding in compliance with environmental regulations.

- Safety Inspections: GAO’s Drones can access hard-to-reach or hazardous areas of a mine for safety inspections, allowing for quick identification of potential risks and maintenance needs without putting human workers at risk.

- Security and Surveillance: GAO’s Drones equipped with thermal cameras and night vision can provide 24/7 surveillance of mining sites, helping to deter theft, vandalism, and unauthorized access.

- Infrastructure Inspection: GAO’s Drones can inspect mining infrastructure such as conveyor belts, pipelines, and equipment for signs of wear and tear, facilitating proactive maintenance and reducing downtime.

- Blast Monitoring: GAO’s Drones can capture data before, during, and after controlled blasting operations, helping to ensure safety and assess the effectiveness of blasting techniques.

- Haul Road Monitoring: GAO’s Drones can monitor the condition of haul roads and suggest maintenance or repair actions to prevent accidents and reduce wear and tear on mining vehicles.

- Water Management: GAO’s Drones can inspect and monitor water reservoirs, tailings dams, and drainage systems to prevent water-related issues and ensure proper water management within mining operations.

- Emergency Response: In the event of an emergency, such as a mine collapse or fire, GAO’s drones can provide real-time aerial views of the situation, aiding in search and rescue efforts.

- Training and Simulation: GAO’s Drones can be used for training purposes, allowing operators to practice tasks like equipment operation and emergency response in a safe and controlled environment.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the support activities for mining industry:

- Equipment Monitoring: GAO’s IoT sensors can be attached to mining equipment and machinery to continuously monitor their performance, including temperature, pressure, vibration, and fuel consumption. This data helps predict maintenance needs, reduce downtime, and optimize equipment usage.

- Predictive Maintenance: GAO’s IoT-enabled predictive maintenance systems analyze equipment data to identify patterns and anomalies, allowing for proactive maintenance to prevent unexpected breakdowns and costly repairs.

- Safety Monitoring: GAO’s IoT sensors and wearables can track the location and health of miners in real time. They can also monitor environmental conditions, such as gas levels and air quality, to ensure worker safety.

- Asset Tracking: GAO’s RFID and GPS-enabled IoT devices can track the location and movement of assets, including equipment, vehicles, and materials, providing real-time visibility into their status and preventing theft or loss.

- Energy Management: GAO’s IoT solutions can monitor energy consumption within mining operations, optimizing energy usage and reducing costs by identifying areas where energy efficiency can be improved.

- Environmental Compliance: GAO’s IoT sensors can monitor environmental factors such as water quality, emissions, and noise levels, helping mining companies adhere to environmental regulations and minimize their ecological footprint.

- Fleet Management: GAO’s IoT-enabled fleet management systems track the location, fuel consumption, and performance of mining vehicles, allowing for efficient routing, maintenance scheduling, and fuel cost reduction.

- Supply Chain Optimization: GAO’s IoT devices can track the movement of raw materials, ore, and finished products throughout the supply chain, providing real-time visibility and helping to streamline logistics.

- Drill and Blast Optimization: GAO’s IoT sensors and monitoring systems can improve drilling and blasting operations by optimizing drill bit performance, explosives usage, and blast design to maximize ore recovery and minimize environmental impact.

- Water Management: GAO’s IoT sensors can monitor water resources and usage within mining operations, enabling efficient water management and minimizing water-related risks.

- Remote Operation and Automation: GAO’s IoT technologies enable remote operation and automation of mining equipment, reducing the need for on-site personnel in hazardous environments and improving overall efficiency.

- Data Analytics: GAO’s IoT-generated data can be analyzed to gain insights into mining operations, helping to make data-driven decisions for process improvement, cost reduction, and optimization.

- Security and Surveillance: GAO’s IoT-enabled security systems, including cameras and sensors, can enhance site security by monitoring and detecting unauthorized access, intruders, and safety breaches.

- Tailings Management: GAO’s IoT sensors can monitor the stability and environmental impact of tailings dams, providing early warnings of potential issues and ensuring compliance with safety and environmental regulations.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Support Activities for Mining

GAO RFID Inc. has helped many companies in support activities for mining to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000-6

- ISO 14443

- ISO 15693

- Bluetooth 4.0

- Bluetooth 5.0

- GATT (Generic Attribute Profile)

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- OASIS MQTT and MQTT-SN

- OPC UA

- IEEE 802.15.4

Government Regulations

- Mine Safety and Health Administration (MSHA) Regulations

- Environmental Protection Agency (EPA) Regulations

- Occupational Safety and Health Administration (OSHA) Regulations

- Bureau of Land Management (BLM) Regulations

- Federal Energy Regulatory Commission (FERC) Regulations

- S. Army Corps of Engineers (USACE) Regulations

- Department of Transportation (DOT) Regulations

- National Environmental Policy Act (NEPA) Requirements

- Clean Water Act (CWA) Regulations

- Clean Air Act (CAA) Regulations

- Resource Conservation and Recovery Act (RCRA) Regulations

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) Requirements

- Endangered Species Act (ESA) Regulations

- National Historic Preservation Act (NHPA) Compliance

- Federal Mine Safety and Health Act (FMSHA) Regulations

Canadian Government Regulations

- Canadian Environmental Assessment Act (CEAA)

- Canadian Environmental Protection Act (CEPA)

- Fisheries Act

- Navigation Protection Act

- Canadian Nuclear Safety Commission (CNSC) Regulations

- Transportation of Dangerous Goods (TDG) Regulations

- Health and Safety Regulations (varies by province/territory)

- Explosives Act and Regulations

- Natural Resources Canada (NRCan) Regulations

- Canadian Minerals and Metals Plan (CMMP) Requirements

- Provincial and Territorial Mining Regulations (varies by province/territory)

- Aboriginal Consultation and Engagement Requirements (varies by region)

- Canadian Labour Code (for certain mining activities)

- Transportation Regulations (e.g., Transport Canada regulations for shipping hazardous materials)

- Canadian Environmental Assessment Agency (CEAA) Guidelines

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in support activities for mining such as:

Personnel Management Applications:

- Employee Scheduling

- Training and Certification Tracking

- Safety Compliance Monitoring

- Health and Wellness Programs

- Payroll and Compensation Management

Equipment Management Applications:

- Asset Tracking and Maintenance

- Predictive Maintenance

- Equipment Health Monitoring

- Equipment Performance Optimization

- Inventory Control

Access Control Applications:

- Site Entry Control

- Restricted Area Access

- Visitor Management

- Security Monitoring

Warehouse Management Applications:

- Inventory Tracking

- Stockpile Measurement

- Material Handling

- Order Fulfillment

- Inventory Replenishment

Supply Chain Management Applications:

- Supplier Relationship Management

- Procurement and Sourcing

- Logistics and Transportation Management

- Demand Forecasting

- Vendor Performance Analysis

Other Applications:

- Environmental Monitoring

- Compliance Reporting

- Drill and Blast Optimization

- Emergency Response

- Geospatial Data Analysis

- Reporting and Analytics

- Stakeholder Engagement

- Sustainability Initiatives

- Geological Data Analysis

- Waste Management

GAO has enabled its customers to make use of some of the leading software and cloud services in support activities for mining industry. Below are some of popular software and cloud services in support activities for mining

SAP SuccessFactors, Oracle HCM Cloud, and Workday HCM. For equipment management, prominent options are IBM Maximo, Infor EAM, and Maintenance Connection. Commercial cloud services commonly used for these purposes encompass Microsoft Azure, Amazon Web Services (AWS), Google Cloud Platform (GCP), Hexagon Mining, Deswik Suite, RPMGlobal’s software solutions, Microsoft Azure, Amazon Web Services (AWS), and Google Cloud Platform (GCP).

GAO has worked with some of the leading technology companies in support activities for mining in to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in support activities for mining:

IBM, Microsoft, and Oracle, Siemens, ABB, Schneider Electric and Rockwell Automation.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in support activities for mining industry.

In one case study, a large mining company in Nevada utilized RFID technology to enhance equipment maintenance and safety. RFID tags were affixed to mining equipment, and sensors monitored various parameters in real-time, such as temperature, vibration, and usage hours. This data was then processed using predictive maintenance algorithms, allowing the company to perform timely maintenance, prevent equipment breakdowns, and optimize equipment lifespan. In another case, an Arizona-based mining operation employed RFID for inventory and supply chain management. RFID tags were placed on materials, equipment, and spare parts, enabling real-time tracking and automated reordering. This streamlined the supply chain, reduced inventory carrying costs, and ensured that critical materials were always available, ultimately increasing operational efficiency.

A mining company in Canada implemented an RFID-based asset tracking system to monitor the location and maintenance status of critical mining equipment. By attaching RFID tags to machinery and using fixed and mobile RFID readers, they achieved real-time visibility into the equipment’s utilization and condition. This allowed for predictive maintenance, reducing downtime, and improving overall operational efficiency.

Another case study involves a Canadian mining operation using RFID technology to streamline inventory management and stockpile measurement. RFID tags were affixed to mining materials and placed strategically throughout the site. This enabled automated inventory tracking, reducing manual labor, minimizing stockouts, and enhancing the accuracy of stockpile measurements, which is crucial for optimizing resource management.

A mining company in Canada prioritized personnel safety by implementing RFID-based access control and safety monitoring systems. Workers were issued RFID badges, and RFID readers were installed at entry points, machinery, and hazardous zones. The system ensured that only authorized personnel could access restricted areas and automatically tracked workers’ movements. In emergencies, it facilitated rapid evacuation and helped locate personnel, enhancing safety measures within the mining operation.

In line with Canada’s stringent environmental regulations, a mining company utilized RFID sensors to monitor and track environmental conditions around its mining site. These sensors collected data on water quality, air emissions, and noise levels, which were crucial for regulatory compliance. The real-time data allowed the company to proactively address environmental concerns and demonstrate their commitment to sustainable mining practices. A major mining company in Mexico implemented an RFID-based asset tracking system to monitor the location and health of their mining equipment and machinery. By using RFID tags and sensors, they were able to track equipment movement within the mine, schedule predictive maintenance based on usage data, and reduce downtime significantly. This led to increased operational efficiency and cost savings.

One case study involves the use of RFID for personnel tracking and safety in underground mines in Sweden. RFID badges were provided to miners, allowing real-time tracking of their locations within the mine, ensuring timely response in case of emergencies and providing valuable data for optimizing work processes. Another case study from Germany highlights RFID’s role in equipment maintenance and inventory management. RFID tags were attached to mining equipment, enabling automated tracking of maintenance schedules and spare parts inventory, reducing downtime and maintenance costs. Additionally, these RFID solutions ensured compliance with safety regulations and minimized the risk of equipment-related incidents.

One such case study could involve the use of UHF RFID for equipment tracking and maintenance. In this scenario, RFID tags would be affixed to mining machinery and equipment, enabling real-time tracking of their locations and conditions. This data could be integrated into a centralized asset management system, allowing for proactive maintenance scheduling based on usage and wear-and-tear patterns. Another case study might focus on stockpile management, where UHF RFID tags are attached to bulk materials such as ore or coal. RFID readers placed at various points in the supply chain could track material movement, ensuring accurate inventory levels, optimizing reordering processes, and preventing stockouts or overstock situations.

Many applications of RFID by GAO can be found here.

Case Studies of IoT Applications

Below are some IoT application cases in support activities for mining industry.

One case study involves a major copper mining operation in Arizona utilized IoT sensors to monitor equipment health and reduce downtime. By continuously collecting data on factors like temperature, vibration, and equipment performance, the mine implemented predictive maintenance strategies, resulting in a significant reduction in unexpected breakdowns and maintenance costs. In another case, a coal mining company in West Virginia employed IoT technology for safety monitoring. Wearable IoT devices equipped with sensors were issued to miners to monitor vital signs and detect environmental hazards. Real-time data from these devices helped ensure worker safety by providing immediate alerts in case of emergencies or health issues. Additionally, IoT sensors were used to monitor air quality, methane levels, and other environmental factors, contributing to regulatory compliance and minimizing the environmental impact of mining operations.

One such application involves the implementation of IoT sensors for environmental monitoring. In a hypothetical case study, IoT sensors could be deployed to continuously monitor air and water quality, noise levels, and other environmental factors around a mining site. This data would be transmitted in real-time to a central system, ensuring compliance with environmental regulations and enabling immediate response to any issues that could impact the surrounding ecosystem. Another potential use case is in predictive maintenance for mining equipment. IoT sensors attached to machinery could collect data on temperature, vibration, and other indicators of equipment health. Through data analysis and machine learning algorithms, mining companies could predict when equipment is likely to fail and schedule maintenance proactively, reducing downtime and maintenance costs.

An underground mine deployed IoT sensors to monitor air quality, humidity, and temperature in real time, ensuring the well-being of miners and compliance with safety regulations. Another case study from Finland demonstrated the use of IoT in predictive maintenance, where sensors installed on mining equipment gathered data on vibrations, temperature, and lubrication status. This data allowed maintenance teams to proactively identify potential issues, reducing downtime and extending equipment lifespan. Additionally, a mining operation in Spain utilized IoT sensors to track water usage and quality in nearby rivers, aiding in environmental compliance and responsible water management practices.

Case Studies of Drone Applications

Below are some drone application cases in support activities for miningt industry.

A large open pit mine adopted drone technology to conduct volumetric surveys of stockpiles and monitor pit progress. This not only reduced surveying time from weeks to hours but also improved safety by minimizing the need for ground personnel in high-risk areas. In Minnesota, a mining company employed drones equipped with LiDAR sensors to create highly detailed terrain models, aiding in mine planning and environmental impact assessments. Furthermore, in Arizona, drones were used for inspecting the structural integrity of tailings dams and monitoring environmental conditions in real-time, ensuring regulatory compliance and mitigating potential risks.

A large-scale open pit mine employed drones equipped with LiDAR sensors to conduct topographic surveys, achieving remarkable time and cost savings compared to traditional surveying methods. In the United Kingdom, a quarrying operation utilized drones for volumetric analysis of stockpiles, providing accurate inventory data and reducing manual labor requirements. Additionally, in Norway, drones were employed for safety inspections of hazardous areas within mining sites, mitigating risks associated with human presence in dangerous locations.

GAO RFID Systems & Hardware for Support Activities for Mining

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including support activities for mining.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

- BLE Gateway (Receiver)

- as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

- BLE Tags/Beacons

GAO’s BLE technology is suitable for many industries, including support activities for mining.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including support activities for mining:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including support activities for mining:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including support activities for mining:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including support activities for mining:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 KHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones are offered:

The RFID systems by GAO are highly popular for clients in support activities for mining:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include drilling rigs, seismic survey instruments, core sampling equipment, geological survey tools, heavy machinery (e.g., excavators, bulldozers, haul trucks), crushers, processing machinery, safety equipment (e.g., helmets, respirators), communication and monitoring systems, environmental monitoring equipment, explosives handling equipment, and specialized maintenance and repair tools for mining equipment.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for support activities for mining and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in support activities for mining we have worked with to serve our joint customers:

- Accenture

- Deloitte

- PricewaterhouseCoopers (PwC)

- KPMG

- IBM Global Business Services

- Capgemini

- CGI

- Wipro

- Cognizant

- DXC Technology

- Infosys

- Tata Consultancy Services (TCS)

- Ernst & Young (EY)

- Booz Allen Hamilton

- Hitachi Consulting

GAO Has Served Support Activities for Mining Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in support activities for mining industry to achieve success in digital transformation, IoT (Internet of Things), automation, AI (Artificial Intelligence), predictive maintenance, sustainability, environmental compliance, remote monitoring, data analytics, blockchain, 5G connectivity, autonomous vehicles, electrification, circular economy, and zero-emission mining.

GAO RFID Inc. has served many customers in support activities for mining, including its various divisions such as:

- Exploration and Drilling Services: This sub-industry focuses on geological surveying, mineral prospecting, and drilling to identify and assess potential mining sites.

- Mining Services: Companies in this division provide services related to the actual extraction of minerals or ores, including excavation, blasting, and ore processing.

- Mineral and Ore Transportation: This sub-industry focuses on logistics and transportation of mined materials, including haulage, shipping, and rail transport.

- Equipment Manufacturing and Maintenance: Companies that design, manufacture, and maintain mining equipment and machinery fall into this category.

- Safety and Environmental Services: This division includes firms specializing in safety consulting, environmental impact assessments, and compliance with regulatory requirements.

- Geological and Geophysical Services: This sub-industry provides geological surveying, mapping, and geophysical analysis to support mining operations.

- Waste Management and Remediation Services: Companies in this division handle waste disposal and environmental remediation, ensuring responsible and sustainable mining practices.

- Consulting and Technology Services: This category includes technology providers and consulting firms that offer digital solutions, data analytics, and process optimization services to mining companies.

GAO’s technologies enable its customers in support activities for mining to effectively track their workforces such as miners, geologists, drillers, blasters, engineers, equipment operators, safety inspectors, environmental specialists, surveyors, logistics coordinators, maintenance technicians, electricians, data analysts, consultants, and contractors that effectively track operational assets such as drills, excavators, bulldozers, haul trucks, crushers, conveyor systems, generators, explosives handling equipment, safety gear (e.g., helmets, respirators), surveying instruments, heavy-duty maintenance tools, environmental monitoring devices, processing machinery, and communication and monitoring systems.

Here are some of the leading companies in support activities for mining industry GAO has served:

- Jacobs Engineering Group

- Tetra Tech

- Kiewit Corporation

- Bechtel Corporation

- AECOM

- Fluor Corporation

- WSP USA

- HDR

- Wood Plc

- Black & Veatch

- Worley

- Stantec

- SNC-Lavalin

- Golder Associates

- ABB

- Schneider Electric

- Siemens USA

- Komatsu America

- DMC Mining Services Canada

- CWA Engineers Inc.

- Cementation Canada Inc.

- Nordmin Group of Companies

- Thurber Engineering Ltd.

- Halyard In

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com