![]()

Index

GAO Software Provides Easy Integration with API

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for telecommunications equipment manufacturing

GAO Makes Efforts to Satisfy Customers

GAO Has Served telecommunications equipment manufacturing extensively

Overview

The telecommunications equipment manufacturing industry plays a pivotal role in the global communication infrastructure by designing, producing, and distributing a wide range of essential hardware and technology components. This industry encompasses the development of equipment such as mobile phones, landline phones, network routers, switches, transmitters, and receivers, as well as various other devices required for data transmission, voice communication, and internet connectivity. Telecommunications equipment manufacturers are responsible for creating cutting-edge technology that enables the seamless transfer of data and voice signals across vast distances. These companies often invest heavily in research and development to stay at the forefront of innovation, continuously improving the performance, efficiency, and security of their products. They also adapt to evolving communication standards, such as 5G and beyond, to meet the growing demands of consumers, businesses, and governments for faster and more reliable communication networks.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the Telecommunications equipment manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as storage tanks and containers for bulk chemicals, chemical pumps and transfer equipment, specialized handling equipment like forklifts and pallet jacks, safety equipment such as Assembly Lines, Quality Control Systems, Testing Equipment, Soldering Stations, Surface Mount Technology (SMT) Machines, Pick-And-Place Machines, Reflow Ovens, And Precision Machining Tools.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for telecommunications equipment manufacturing industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Telecommunications Equipment Manufacturing

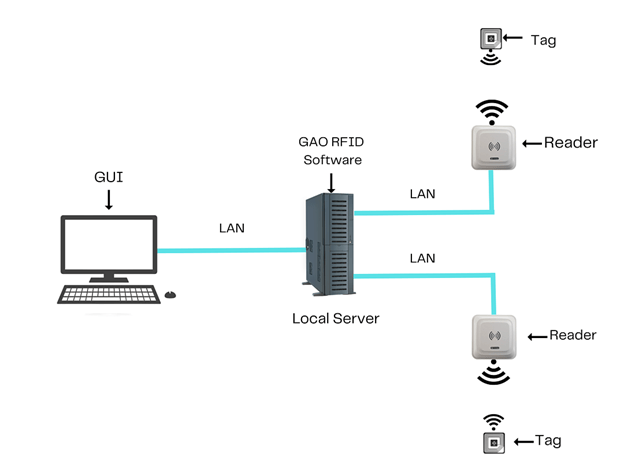

To satisfy its customers, GAO’s RFID or RFID Systems for telecommunications equipment manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for telecommunications equipment manufacturing software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for telecommunications equipment manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for telecommunications equipment manufacturing software running on a local server.

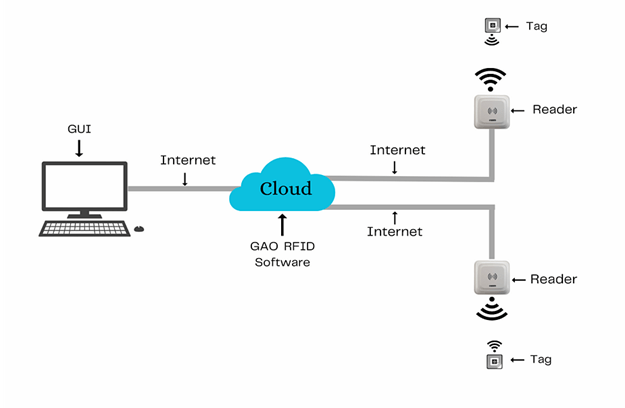

The above illustrates GAO system for Telecommunications equipment manufacturing with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in telecommunications equipment manufacturing industry:

- Inventory Management: GAO’S RFID tags can be used to track and manage inventory of raw materials, components, and finished products in real-time, improving supply chain efficiency.

- Asset Tracking: GAO’S RFID tags on equipment and machinery can help monitor the location and status of assets within manufacturing facilities, reducing loss and improving maintenance.

- Work-in-Progress (WIP) Tracking: GAO’S RFID can be used to monitor the progress of products through various manufacturing stages, providing insights into production efficiency and bottlenecks.

- Quality Control: GAO’S RFID tags can be attached to products to record data related to quality control tests and inspections, ensuring product quality and traceability.

- Maintenance and Repairs: GAO’S RFID-enabled equipment can facilitate proactive maintenance by tracking usage and providing alerts for servicing and repairs.

GAO’s drone technologies find the following applications in the Telecommunications equipment manufacturing industry:

- Facility Inspection: GAO’s Drones equipped with cameras and sensors can perform aerial inspections of manufacturing facilities, helping identify maintenance issues and ensuring safety compliance.

- Inventory Surveillance: GAO’s Drones can be used for aerial surveillance of outdoor inventory storage areas, monitoring for theft or unauthorized access.

- Environmental Monitoring: GAO’s Drones can assess environmental factors such as temperature, humidity, and air quality in manufacturing facilities to ensure optimal working conditions.

- Security: GAO’s Drones can enhance security by providing real-time monitoring of manufacturing sites, detecting intrusions, and assisting in emergency response.

- Supply Chain Management: GAO’s Drones can be used for tracking the movement of materials and components within the supply chain, improving logistics and reducing transit times.

- Surveying and Mapping: GAO’s Drones can create accurate 3D maps and models of manufacturing sites, aiding in site planning, construction, and infrastructure maintenance.

- Remote Monitoring: GAO’s Drones can assist in remote monitoring of equipment and infrastructure in challenging or inaccessible locations.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the telecommunications equipment manufacturing industry:

- Predictive Maintenance: GAO’s IoT sensors can monitor the condition of manufacturing equipment and machinery, predicting when maintenance is needed to prevent breakdowns and reduce downtime.

- Quality Control: GAO’s IoT sensors can track and record data during the manufacturing process, ensuring that products meet quality standards, and alerting operators to deviations.

- Inventory Management: GAO’s IoT systems can automate inventory tracking, optimizing stock levels, reducing excess inventory, and ensuring that necessary components are always available.

- Energy Management: GAO’s IoT devices can monitor energy consumption in manufacturing facilities, allowing for more efficient energy usage and cost savings.

- Supply Chain Visibility: GAO’s IoT can provide real-time visibility into the movement and location of raw materials, components, and finished products throughout the supply chain.

- Process Optimization: GAO’s IoT analytics can analyze data from various stages of manufacturing to identify process inefficiencies and opportunities for improvement.

- Remote Monitoring and Control: Manufacturers can remotely monitor and control equipment and processes, enabling adjustments and troubleshooting without on-site presence.

- Asset Tracking: GAO’s IoT enables real-time tracking of valuable assets, such as equipment, tools, and vehicles, reducing the risk of loss or theft.

- Worker Safety: GAO’s IoT sensors can monitor worker safety conditions, such as temperature, humidity, and the presence of hazardous gases, ensuring a safe working environment.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Telecommunications Equipment Manufacturing Industry

GAO RFID Inc. has helped many companies in telecommunications equipment manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ASTM F38 – Unmanned Aircraft Systems

- ISO 21384 – Unmanned aircraft systems

- FAA Part 107 – Small Unmanned Aircraft Regulations (U.S.)

- JARUS – Joint Authorities for Rulemaking on Unmanned Systems

- ANSI/CTA-2063 – Standard for Remote ID and Tracking

- ICAO Annex 2 – Rules of the Air (International Civil Aviation Organization)

- ISO 18000

- EPCglobal

- ISO 15693

- ISO 14443

- Bluetooth SIG Standards

- Bluetooth 4.0

- Bluetooth 5.0 and later

- IEEE 802.11

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- OPC UA (Unified Architecture)

- Thread

- LoRaWAN

Government Regulations

- Federal Communications Commission (FCC) Regulations

- National Institute of Standards and Technology (NIST) Regulations

- S. Customs and Border Protection (CBP) Regulations

- Occupational Safety and Health Administration (OSHA) Regulations

- Environmental Protection Agency (EPA) Regulations

- National Electrical Code (NEC)

- National Telecommunications and Information Administration (NTIA) Regulations

- Department of Commerce Export Administration Regulations (EAR)

- Federal Acquisition Regulation (FAR) – for government contracts

Canadian Government Regulations

- Innovation, Science, and Economic Development Canada (ISED) Regulations

- Canadian Radio-television and Telecommunications Commission (CRTC) Regulations

- Industry Canada Regulations

- Canada Border Services Agency (CBSA) Regulations

- Health Canada Regulations (for radiofrequency emissions)

- Canadian Environmental Protection Act (CEPA) Regulations

- Canadian Standards Association (CSA) Standards

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in Telecommunications equipment manufacturing such as:

Personnel Management:

- Employee Attendance Tracking

- Workforce Scheduling and Shift Management

- Training and Certification Management

- Health and Safety Compliance Monitoring

- Performance Evaluation and Appraisal

Equipment Management:

- Preventive and Predictive Maintenance

- Asset Tracking and Monitoring

- Equipment Calibration and Testing

- Equipment Utilization Optimization

- Inventory Control for Spare Parts

Access Control:

- Physical Access Control to Manufacturing Facilities

- Data Security and Access Control for Sensitive Information

- Biometric Authentication for Secure Access

Warehouse Management:

- Inventory Tracking and Management

- Just-In-Time Inventory Management

- Order Fulfillment and Picking

- RFID-Based Warehouse Automation

- Shipping and Receiving Management

Supply Chain Management:

- Supplier Relationship Management

- Demand Forecasting and Planning

- Transportation and Logistics Management

- Supplier Quality Control

- Procurement and Purchase Order Management

Other Applications:

- Quality Control and Assurance

- Product Lifecycle Management (PLM)

- Research and Development Collaboration

- Environmental Compliance and Sustainability Monitoring

- Customer Relationship Management (CRM)

- Sales and Order Processing

- Financial Management and Accounting

GAO has enabled its customers to make use of some of the leading software and cloud services in the Telecommunications equipment manufacturing industry. Below are some of the popular software and cloud services in telecommunications equipment manufacturing such as SAP SuccessFactors, Workday HCM, Oracle Human Capital Management, ADP Workforce Now, and Kronos Workforce Central. For equipment management, notable options are IBM Maximo, Infor EAM, Oracle Enterprise Asset Management, Fiix (formerly Maintenance Assistant), and eMaint CMMS. Access control solutions encompass LenelS2 OnGuard, Honeywell Access Control, HID Global’s Access Control, Genetec Security Center, and Avigilon Access Control Manager. In the realm of warehouse management, top choices consist of Manhattan Associates Warehouse Management, HighJump Warehouse Management System (WMS), Oracle Warehouse Management Cloud, JDA Warehouse Management, and Blue Yonder (formerly JDA) Warehouse Management. In supply chain management, SAP Integrated Business Planning (IBP), Oracle Supply Chain Management Cloud, Kinaxis RapidResponse, Infor Nexus Supply Chain Management, and Blue Yonder.

GAO has worked with some of the leading technology companies telecommunications equipment manufacturing to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in telecommunications equipment manufacturing such as Ericsson, Nokia Corporation, Huawei Technologies, Cisco Systems, Inc., Qualcomm Incorporated, and Juniper Networks, Inc.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in telecommunications equipment manufacturing industry.

In a major U.S. telecommunications equipment manufacturing plant, RFID technology was implemented to optimize inventory management. RFID tags were used to track the movement of components and equipment throughout the production process, resulting in a 20% reduction in inventory carrying costs and a 15% increase in production efficiency.

A Canadian telecommunications equipment manufacturer integrated RFID for quality control purposes. RFID tags were attached to individual products, allowing for real-time monitoring of production parameters and quality checks. This system helped reduce defects by 18% and improved overall product quality.

In Mexico, a telecommunications equipment manufacturer deployed RFID to enhance its supply chain efficiency. RFID-enabled containers and pallets were used to track the movement of materials between manufacturing facilities and distribution centers. This initiative reduced transit times by 25% and improved overall supply chain visibility.

A leading European telecommunications equipment manufacturer adopted RFID for asset tracking across multiple facilities. RFID tags were attached to valuable equipment, ensuring their accurate location and status. This implementation reduced equipment loss and improved asset utilization rates.

Many applications of RFID by GAO can be found here.

Case Studies of IoT Applications

Below are some IoT application cases in the telecommunications equipment manufacturing industry.

In the USA, a telecommunications equipment manufacturer utilized IoT sensors to monitor the condition of manufacturing machinery. Predictive maintenance algorithms analyzed data from sensors, resulting in a 30% reduction in downtime and a 20% increase in equipment lifespan.

A Canadian telecommunications equipment manufacturer implemented IoT for environmental monitoring in its production facilities. Sensors tracked temperature, humidity, and air quality, ensuring compliance with safety regulations and creating a safer working environment.

In Mexico, a telecommunications equipment manufacturer embraced IoT for supply chain optimization. IoT devices provided real-time visibility into the movement of materials and components, improving logistics and reducing transit times by 15%.

A European telecommunications equipment manufacturer leveraged IoT for remote monitoring of equipment performance. IoT-enabled sensors allowed engineers to assess equipment status and performance from a central location, reducing the need for on-site visits and enhancing overall operational efficiency.

Case Studies of Drone Applications

Below are some drone application cases in the telecommunications equipment manufacturing industry.

A prominent U.S. telecommunications equipment manufacturer employed drones for facility inspection. Drones equipped with cameras and sensors conducted aerial inspections of manufacturing facilities, identifying maintenance needs and ensuring compliance with safety standards.

In Canada, a telecommunications equipment manufacturer used drones for inventory surveillance. Aerial drones monitored outdoor inventory storage areas, enhancing security and minimizing the risk of theft.

A Mexican telecommunications equipment manufacturer employed drones for environmental monitoring. Drones assessed environmental factors in and around their manufacturing facilities, ensuring a safe and compliant working environment.

A leading European telecommunications equipment manufacturer utilized drones for site surveying and mapping. Drones created accurate 3D maps of manufacturing sites, aiding in site planning and infrastructure maintenance.

GAO RFID Systems & Hardware for Telecommunications Equipment Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including Telecommunications equipment manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including Telecommunications equipment manufacturing.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Telecommunications equipment manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including Telecommunications equipment manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Telecommunications equipment manufacturing:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including Telecommunications equipment manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones is offered:

The RFID systems by GAO are highly popular for clients in Telecommunications equipment manufacturing:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include storage tanks and containers, chemical pumps and transfer equipment, forklifts and pallet jacks, safety equipment (e.g., protective clothing, gloves, respirators), labeling and packaging machinery, quality control and testing equipment, computer systems for inventory management, transportation vehicles (e.g., trucks, tankers), climate-controlled storage warehouses, and specialized handling equipment for hazardous materials.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for Telecommunications equipment manufacturing and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in telecommunications equipment manufacturing we have worked with to serve our joint customers:

- Accenture

- Deloitte

- Capgemini

- Cognizant

- IBM Global Business Services

- PricewaterhouseCoopers (PwC)

- Wipro

- Ernst & Young (EY)

- Infosys

- DXC Technology

- HCL Technologies

- Tata Consultancy Services (TCS)

- Atos

- NTT Data

- CGI Group

- Compugen Inc.

- Long View Systems

- Scalar Decisions

- CDW Canada

- Softchoice

- OnX Enterprise Solutions

- Sierra Systems (an NTT Data Company)

- Bell Canada

- Insight Canada

- TeraMach Technologies

- Cogeco Peer 1

- Scalar Decisions

- OnX Enterprise Solutions

- Compufix Solutions

- PCL Constructors Canada Inc. (PCL)

- Sopra Steria

- TietoEVRY

GAO Has Served Telecommunications Equipment Manufacturing Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in telecommunications equipment manufacturing industry to achieve success in

5G deployment and optimization, network virtualization, IoT integration, edge computing, sustainability initiatives, supply chain resilience, and cybersecurity enhancements. Companies are also focusing on AI-driven automation, software-defined networking (SDN), and Open RAN

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in telecommunications equipment manufacturing, including many in its various divisions such as:

- Network Equipment Manufacturers: These companies produce hardware and software components that form the backbone of telecommunications networks. This includes routers, switches, optical networking equipment, and related infrastructure.

- Wireless Communication Equipment Manufacturers: This division focuses on manufacturing wireless communication equipment such as base stations, antennas, and transceivers for cellular and wireless networks.

- Fiber Optic Equipment Manufacturers: Companies in this division specialize in the production of fiber optic cables, connectors, and related equipment, essential for high-speed data transmission in telecommunications.

- Mobile Device Manufacturers: These companies design and produce mobile devices, including smartphones, tablets, and feature phones, as well as their associated accessories.

- Satellite Communication Equipment Manufacturers: This division is involved in the production of satellite communication equipment, including satellite ground stations, dishes, and modems.

- Broadcasting Equipment Manufacturers: Manufacturers in this division produce equipment for television and radio broadcasting, such as transmitters, antennas, and signal processing devices.

- Testing and Measurement Equipment Manufacturers: Companies in this segment create equipment for testing and measuring the performance of telecommunications networks, ensuring quality and compliance with industry standards.

- Accessory and Component Manufacturers: These manufacturers produce components and accessories used in telecommunications equipment, including power supplies, connectors, and enclosures.

- Software Developers: This division focuses on developing software solutions for telecommunications, including network management software, billing systems, and communication protocol stacks.

- Research and Development: This sector encompasses organizations and departments dedicated to research and innovation in telecommunications technology, driving advancements in the industry.

- Support and Services Providers: Companies offering installation, maintenance, and support services for telecommunications equipment fall into this category.

- Supply Chain and Logistics Companies: These entities play a critical role in managing the supply chain, sourcing components, and ensuring timely delivery of equipment to manufacturers.

- Cybersecurity and Network Security Providers: In an era of heightened cybersecurity threats, these companies specialize in developing security solutions to protect telecommunications networks and equipment.

GAO’s technologies enable its customers in Telecommunications equipment manufacturing to effectively track their workforces such as sales representatives, product specialists, warehouse managers, logistics coordinators, chemical engineers, safety officers, quality control analysts, procurement specialists, inventory managers, customer service representatives, compliance officers, and supply chain managers effectively track operational assets such as storage tanks, chemical pumps, drum handling equipment, forklifts, pallet jacks, labeling machines, packaging machinery, conveyor systems, quality control and testing equipment, temperature and humidity sensors, RFID systems, inventory management software, safety showers and eyewash stations, hazmat storage cabinets, spill containment pallets, and transportation vehicles such as trucks and tankers.

Here are some of the leading companies in telecommunications equipment manufacturing industry GAO has served:

- Cisco Systems, Inc.

- Qualcomm Incorporated

- Corning Incorporated

- L3Harris Technologies, Inc.

- ViaSat, Inc.

- Harris Corporation

- Juniper Networks, Inc.

- Ciena Corporation

- Infinera Corporation

- Motorola Solutions, Inc.

- Extreme Networks, Inc.

- Calix, Inc.

- ADTRAN, Inc.

- JMA Wireless

- EchoStar Corporation

- Casa Systems, Inc.

- RADCOM Ltd.

- Westell Technologies, Inc.

- Airspan Networks Inc.

- JDS Uniphase Corporation

- Ribbon Communications Inc.

- Sierra Wireless, Inc.

- Powerwave Technologies, Inc.

- Spirent Communications, Inc.

.

.

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com