Index

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Wood Product Manufacturing

GAO Helps Customers Comply with Standards, Mandates & Regulations of Wood Product Manufacturing

GAO Software Provides Easy Integration with API

Case Studies of RFID, IoT & Drone Applications

GAO RFID Systems & Hardware for Wood Product Manufacturing

Overview

The wood product manufacturing industry encompasses a diverse range of activities related to the processing and fabrication of wood materials, transforming raw timber into a wide array of products such as lumber, plywood, furniture, flooring, cabinetry, and various construction materials. This sector involves several stages, including logging, sawmilling, milling, shaping, finishing, and assembly, with a strong emphasis on sustainability practices and quality control to meet the demands of both residential and commercial markets while minimizing environmental impact.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in wood product manufacturing Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as machinery, including sawmill tools like circular and band saws, planers and milling machines, finishing equipment such as sanding machines and coating lines, assembly tools like clamps and nail guns, material handling gear such as forklifts and conveyors, drying kilns, CNC machinery, lathes, dust collection systems, safety equipment, measurement tools, power tools, furniture and cabinetry-specific machines, woodworking benches, pneumatic tools, CAD software, material handling systems, waste disposal equipment, and maintenance tools. The specific equipment needed varies based on product types, production scale, and automation preferences.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for wood product manufacturing. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Wood Product Manufacturing

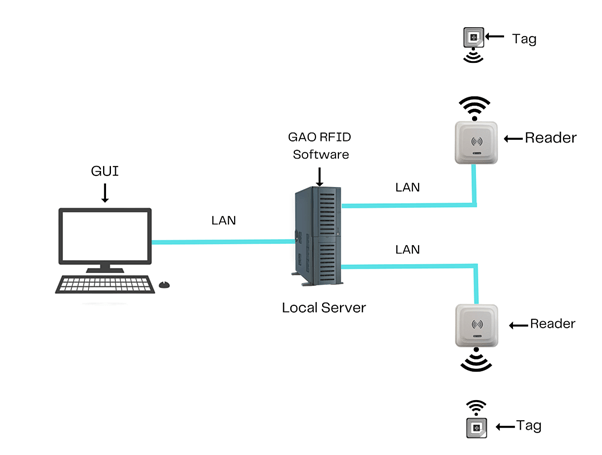

To satisfy its customers, GAO’s RFID or RFID Systems for wood product manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for wood product manufacturing software running on a local server.

To satisfy its customers, GAO’s RFID or RFID Systems for wood product manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premises, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for wood product manufacturing software running on a local server.

The above illustrates GAO system for wood product manufacturing with its software running in cloud

The above illustrates GAO system for wood product manufacturing with its software running in cloud

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in wood product manufacturing industry:

- Inventory Management: GAO’s RFID tags can be attached to raw wood materials, enabling real-time tracking of inventory levels, reducing stockouts, and improving demand forecasting.

- Asset Tracking: GAO’s RFID tags can be affixed to equipment, tools, and machinery, allowing manufacturers to monitor the location and usage of these assets, reducing loss and optimizing maintenance schedules.

- Quality Control: GAO’s RFID tags can store information about the origin of wood products and their manufacturing history, facilitating quality control and traceability to identify and rectify defects or discrepancies.

- Production Monitoring: GAO’s RFID technology can be integrated into production lines to monitor the progress of wood products, ensuring they meet production schedules and quality standards.

- Work-in-Progress (WIP) Tracking: GAO’s RFID tags on semi-finished products help track their movement through different production stages, ensuring efficient workflow and timely completion.

- Supply Chain Visibility: GAO’s RFID can be used throughout the supply chain, from forest to factory to distribution centers, providing visibility into the movement and status of wood products, reducing delays and errors.

- Maintenance and Repairs: GAO’s RFID tags on machinery and equipment can trigger maintenance alerts based on usage or predefined schedules, preventing breakdowns and reducing downtime.

- Authentication and Anti-counterfeiting: GAO’s RFID tags with unique identifiers can be used to authenticate the origin and authenticity of wood products, helping to combat counterfeiting and illegal logging.

- Traceability and Compliance: GAO’s RFID enables comprehensive traceability of wood products, helping manufacturers comply with regulations and certifications related to sustainable sourcing and environmental standards.

- Security and Access Control: GAO’s RFID access cards or badges can control access to restricted areas within manufacturing facilities, ensuring security and safety.

- Shipping and Logistics: GAO’s RFID tags on finished wood products streamline the shipping process, allowing for accurate tracking and monitoring of shipments and ensuring timely delivery to customers.

- Data Collection and Analytics: GAO’s RFID data can be collected and analyzed to gain insights into production efficiency, worker productivity, and supply chain performance, enabling data-driven decision-making.

- Labor Tracking: GAO’s RFID badges for workers can record attendance, monitor productivity, and improve labor management within the manufacturing facility.

- Pallet and Container Tracking: GAO’s RFID tags on pallets and containers help manage the movement and location of products within a facility or during transportation.

- Environmental Monitoring: GAO’s RFID sensors can monitor environmental conditions, such as temperature and humidity, to ensure that wood products are stored and transported under optimal conditions.

GAO’s drone technologies find the following applications in the wood product manufacturing industry:

- Forest Inventory and Management: GAO’s Drones equipped with LiDAR (Light Detection and Ranging) and multispectral sensors can efficiently survey forests, providing accurate data on tree density, species distribution, and overall forest health. This information aids in sustainable forest management and planning for timber harvesting.

- Timber Harvesting Planning: GAO’s Drones can help assess the accessibility and condition of logging sites, enabling more precise planning for timber harvesting operations, reducing environmental impact and optimizing resource allocation.

- Fire Detection and Monitoring: GAO’s Drones equipped with thermal imaging cameras can patrol forested areas to detect and monitor wildfires in real-time, allowing for early intervention and fire management.

- Tree Health Assessment: GAO’s Aerial imagery captured by drones can be used to identify signs of disease, pests, or stress in trees, enabling timely intervention and minimizing losses.

- Illegal Logging Detection: GAO’s Drones can patrol remote forested areas to detect illegal logging activities and provide evidence for law enforcement agencies, helping combat unauthorized deforestation.

- Forest Regeneration: GAO’s Drones can be used to disperse tree seeds and planting materials over large areas, aiding in reforestation and afforestation efforts.

- Harvesting Assistance: GAO’s Drones can assist in logging operations by providing real-time video feeds to operators, helping them navigate through dense forests and ensuring safe and efficient timber extraction.

- Road and Infrastructure Inspection: GAO’s Drones can conduct aerial surveys of forest roads, bridges, and infrastructure to assess their condition, plan maintenance, and ensure safe transportation of timber.

- Wildlife Monitoring: GAO’s Drones can capture images and videos of wildlife populations in and around forestry areas, helping ecologists and conservationists’ study and protect biodiversity.

- Environmental Impact Assessment: GAO’s Drones can document the impact of forestry operations on the environment, including soil erosion, water quality, and habitat disturbance, aiding in compliance with environmental regulations.

- Geospatial Mapping: GAO’s Drones equipped with GPS and mapping technology can create high-resolution 3D maps and digital terrain models (DTMs) of forested areas, improving land management and planning.

- Security and Theft Prevention: GAO’s Drones equipped with surveillance cameras can patrol logging sites and storage areas, deterring theft and vandalism.

- Search and Rescue: In remote forested regions, GAO’s drones can assist in search and rescue operations, providing aerial reconnaissance to locate lost or injured individuals.

- Training and Simulation: GAO’s Drones can be used for training purposes, allowing forestry workers to practice operating heavy machinery in a safe and controlled environment.

- Regulatory Compliance: GAO’s Drones can help forestry companies document their operations to comply with environmental and forestry regulations, facilitating audits and reporting.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the wood product manufacturing industry:

- Asset Tracking: GAO’s IoT sensors can be attached to equipment, tools, and machinery to monitor their location, status, and usage. This helps in preventing loss or theft and ensures timely maintenance.

- Inventory Management: GAO’s IoT sensors can provide real-time data on the inventory of raw materials, work-in-progress items, and finished products. This assists in optimizing stock levels, reducing waste, and automating reordering processes.

- Quality Control: GAO’s Sensors can monitor the manufacturing process and the condition of materials and components in real-time. Any deviations from quality standards can trigger alerts, enabling prompt corrective actions.

- Predictive Maintenance: GAO’s IoT sensors on machinery and equipment can collect data on performance and wear-and-tear. This data is analyzed to predict when maintenance is needed, reducing downtime and costly breakdowns.

- Energy Efficiency: GAO’s IoT systems can control and optimize energy consumption within manufacturing facilities, including lighting, HVAC systems, and machinery operation, leading to energy savings and reduced operational costs.

- Production Line Monitoring: GAO’s IoT devices can track the efficiency of production lines, monitor throughput, and identify bottlenecks or production delays in real-time. This data enables manufacturers to make immediate adjustments for increased productivity.

- Remote Monitoring: GAO’s Manufacturers can remotely monitor and control equipment and processes, allowing for greater flexibility and efficiency in managing operations.

- Supply Chain Visibility: GAO’s IoT sensors can be placed on shipments, providing real-time tracking information as materials and finished products move through the supply chain. This enhances visibility and coordination with suppliers and distributors.

- Environmental Monitoring: GAO’s Sensors can measure and report environmental conditions such as temperature, humidity, and air quality within manufacturing facilities to ensure safe and comfortable working conditions.

- Safety and Compliance: GAO’s IoT can enhance worker safety by monitoring and alerting to potential hazards, such as equipment malfunctions, falls, or accidents. It can also ensure compliance with safety regulations and standards.

- Customer Engagement: GAO’s IoT-enabled furniture can offer interactive features to customers. For example, smart furniture can adjust settings based on user preferences or provide information about product care and maintenance.

- Waste Reduction: GAO’s IoT systems can help in minimizing waste by monitoring production processes and optimizing material usage.

- Employee Productivity: GAO’s IoT can be used to monitor and analyze employee productivity and work habits, leading to better resource allocation and performance management.

- Customer Feedback and Usage Data: GAO’s IoT can collect data on how customers use and interact with furniture products, providing insights for product improvement and development.

- Customization: GAO’s IoT can enable mass customization by allowing customers to personalize furniture features such as colors, materials, or functionalities through digital interfaces.

- Security and Access Control: GAO’s IoT-based security systems can control access to sensitive areas within manufacturing facilities and monitor unauthorized entry.

- Environmental Sustainability: GAO’s IoT can track and report environmental data related to wood sourcing and production processes, helping manufacturers meet sustainability goals and regulations.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Wood Product Manufacturing

GAO RFID Inc. has helped many companies in wood product manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- Bluetooth Core Specification

- Bluetooth 4.0 and Later Versions

- GATT (Generic Attribute Profile)

- Bluetooth Mesh

- Bluetooth SIG Certification

- iBeacon and Eddystone Protocols

- UUIDs (Universally Unique Identifiers)

- Security Standards

- ISO 18000 Series

- ISO 15693

- ISO 14443

- ISO 18046 Part 1 and Part 2

- EPCglobal Standards

- GS1 Standards

- ASTM E2599-08

- AIM Global Standards

- ISO 18000 Series

- ISO 15693

- ISO 14443

- ISO 18046 Part 1 and Part 2

- EPCglobal Standards

- GS1 Standards

- ASTM E2599-08

- AIM Global Standards

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- HTTP/HTTPS (Hypertext Transfer Protocol/Secure)

- OPC UA (Unified Architecture)

- DDS (Data Distribution Service)

- Thread

- Zigbee

- Bluetooth 5

- LoRaWAN (Long Range Wide Area Network)

- OneM2M

- 6LoWPAN (IPv6 over Low-Power Wireless Personal Area Networks)

- FIWARE (Open-Source Platform for Smart Applications)

- FAA Regulations (United States)

- EASA Regulations (European Union)

- ISO 21384 Series

- ASTM F38 Committee

- ANSI Standards

- ICAO Guidelines

- Drone Manufacturer Standards

- Industry-Specific Guidelines

- Local Regulations

- Safety and Security Guidelines

US Government Regulations

- Occupational Safety and Health Administration (OSHA) Regulations

- Environmental Protection Agency (EPA) Regulations

- Consumer Product Safety Commission (CPSC) Regulations

- Department of Transportation (DOT) Regulations

- Internal Revenue Service (IRS) Regulations (Taxation)

- S. Customs and Border Protection (CBP) Regulations (Import/Export)

- National Fire Protection Association (NFPA) Regulations

- Department of Labor (DOL) Regulations (Labor Standards)

- Department of Commerce Regulations (Export Controls)

- Food and Drug Administration (FDA) Regulations (If applicable, e.g., for finishes)

Canadian Government Regulations

- Canadian Environmental Protection Act (CEPA)

- Canadian Standards Association (CSA) Standards

- Competition Act

- Health Canada Regulations

- Canadian Food Inspection Agency (CFIA) Regulations (If applicable)

- Import and Export Regulations

- Workplace Safety and Health Regulations

- Consumer Product Safety Regulations

- National Building Code (NBC)

- Wood Packaging Regulations (If applicable)

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in wood product manufacturing such as:

Personnel Management:

- Employee Attendance Tracking

- Workforce Scheduling and Shift Management

- Skills and Certification Management

- Employee Training and Development

- Health and Safety Compliance

- Labor Cost Analysis

- Performance Evaluation and Appraisal

- Employee Engagement and Communication

Equipment Management:

- Machinery and Tool Tracking

- Preventive Maintenance Scheduling

- Equipment Performance Monitoring

- Asset Lifecycle Management

- Energy Efficiency Monitoring

- Equipment Downtime Analysis

- Calibration and Quality Control

Access Control:

- Restricted Area Access Control

- Visitor Management

- Security Surveillance Integration

- Biometric Authentication

- Audit Trails and Logging

Warehouse Management:

- Inventory Tracking and Control

- Order Fulfillment and Picking Optimization

- Just-In-Time Inventory Management

- Warehouse Space Optimization

- Quality Control and Inspection

- Packaging and Labeling

- Shipment Verification

Supply Chain Management:

- Supplier Relationship Management

- Demand Forecasting and Planning

- Materials Sourcing and Procurement

- Transportation and Logistics Optimization

- Vendor Performance Tracking

- Customs and Trade Compliance

- Reverse Logistics (Returns)

- Sustainability and Eco-Friendly Sourcing

Other Applications:

- Quality Assurance and Compliance

- Product Lifecycle Management (PLM)

- Environmental Impact Assessment

- Customer Relationship Management (CRM)

- Marketing and Sales Analytics

- Product Customization and Personalization

- IoT-Based Smart Furniture

- 3D Printing and Prototyping

- Product Catalog and Online Sales Platforms

- RFID-Based Asset Tracking

GAO has enabled its customers to make use of some of the leading software and cloud services in the wood product manufacturing industry. Below are some of popular software and cloud services in wood product manufacturing such as wood product manufacturing industry, leading commercial software options include SAP SuccessFactors, Workday, ADP Workforce Now, BambooHR, and Kronos Workforce Central, offering solutions for talent management, HR administration, and workforce planning. On the equipment management front, notable choices comprise Maintenance Connection, eMaint CMMS, Fiix, UpKeep, and MPulse Maintenance Software, which assist in tracking equipment, managing maintenance schedules, and optimizing asset performance. The selection should be based on factors such as the scale of the manufacturing operation, specific needs, scalability, and integration capabilities, ensuring improved efficiency and reduced downtime in production processes.

GAO has worked with some of the leading technology companies in wood product manufacturing in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in wood product manufacturing serve the manufacturing industry and can provide tailored solutions for wood product manufacturing include SAP, Microsoft, Oracle, IBM, Siemens, Schneider Electric, ABB, PTC, Rockwell Automation, Epicor Software, Autodesk, and Dassault Systèmes. These companies offer a spectrum of software, hardware, and IT services, encompassing areas such as enterprise resource planning (ERP), industrial automation, IoT, design and engineering, and supply chain management, enabling wood product manufacturers to enhance production efficiency, reduce costs, and optimize various aspects of their operations.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in the wood product manufacturing industry.

In the United States, RFID technology has made substantial inroads into the wood product manufacturing sector. Weyerhaeuser, one of the nation’s largest timber companies, has seamlessly integrated RFID for tracking and managing its timber inventory, with RFID tags affixed to logs and lumber. This implementation facilitates real-time inventory monitoring and enhances supply chain management. Similarly, Georgia-Pacific, a prominent producer of paper and wood products, has harnessed RFID technology within its manufacturing processes to meticulously monitor the movement of raw materials and finished products within its facilities. This strategic adoption has led to heightened production efficiency and precise inventory control measures, showcasing the transformative impact of RFID in optimizing operations within the U.S. wood product manufacturing industry.

In Finland, RFID technology plays a pivotal role in enhancing the wood product manufacturing industry. Metsä Group, a prominent Finnish forest industry company, relies on RFID for tracking timber deliveries from forests to its pulp and paper mills, ensuring streamlined supply chain management and precise data for sustainability reporting. Meanwhile, UPM-Kymmene, a leading European manufacturer of paper and wood products, has adopted RFID to track and trace products within its production process, thereby elevating quality control measures and facilitating compliance with regulatory requirements. These initiatives underscore how RFID technology optimizes operations and fosters regulatory compliance within the Finnish wood product manufacturing sector.

In Mexico, RFID technology has made significant inroads into the wood product manufacturing sector. Masisa, a specialized company in wood-based panels, has seamlessly integrated RFID into its manufacturing facilities to enhance the tracking of raw materials and finished products, ultimately resulting in improved production planning and inventory management. Similarly, ARAUCO, a worldwide leader in the wood product manufacturing industry, has embraced RFID technology to meticulously trace timber and wood products across its supply chain, guaranteeing product traceability and stringent quality control measures. These instances underscore the transformative role of RFID in optimizing operations and ensuring product integrity within Mexico’s wood product manufacturing industry.

In Canada, RFID technology has been embraced by prominent players in the wood product manufacturing sector. Canfor, one of the country’s largest lumber producers, has implemented RFID for the comprehensive tracking and management of its valuable timber assets. RFID tags are strategically employed to monitor the movement of logs and lumber through the production process, resulting in enhanced traceability and streamlined logistics. Simultaneously, Tolko Industries, a leading Canadian forest products company, leverages RFID tags on lumber bundles in its sawmills to optimize inventory management and tracking procedures. This not only ensures precise product counts but also effectively reduces errors, exemplifying how RFID technology is revolutionizing operations within the Canadian wood product manufacturing industry.

Many applications of RFID by GAO can be found here

Case Studies of IoT Applications

Below are some IoT application cases in wood product manufacturing industry.

In the United States, Weyerhaeuser, a leading timber company, has harnessed drone technology to optimize their forest inventory management and timber harvesting planning processes, covering vast expanses of their land holdings. Meanwhile, PotlatchDeltic, a timber investment and real estate management firm, has ventured into employing drones for the crucial task of assessing tree health and monitoring conditions within their forests, demonstrating how drone applications are revolutionizing the wood product manufacturing industry by enhancing efficiency and sustainability.Case Studies of Drone Applications

In Scandinavia, forest-focused organizations have embraced drone technology to revolutionize their operations. Södra, a Swedish forest cooperative, has engaged in projects employing drones to streamline tasks ranging from forest inventory to monitoring tree health, ultimately optimizing wood harvesting practices. Meanwhile, Stora Enso, a major European pulp and paper manufacturer active in Finland and Sweden, has ventured into drone applications to enhance forest management and assess the sustainability of its wood supply chain. In neighboring Finland, the Finnish Forest Center has turned to drones as a means to combat the spread of forest pests and diseases, notably the spruce bark beetle, safeguarding the health of the country’s expansive woodlands. These endeavors illustrate how drone technologies are catalyzing innovative and sustainable approaches within the wood product manufacturing industry across Europe.

In Canada, drone technology has been integrated into the forestry sector to enhance operations. BC Timber Sales in British Columbia has leveraged drones to facilitate timber cruising, enabling efficient assessment of timber volume and quality across diverse forest stands. Meanwhile, Canfor, one of Canada’s largest lumber producers, has delved into the use of drones to evaluate forest health and detect pest infestations in its extensive timberlands. These initiatives underscore how drones are becoming indispensable tools for optimizing forestry practices and sustainability efforts within the Canadian wood product manufacturing industry.

In Mexico, drones have been enlisted to bolster sustainable timber practices and combat illegal logging. Fibra MTY, a Mexican real estate investment trust, has harnessed drone technology for aerial surveys and the monitoring of their forested properties, aiming to enhance sustainable timber production. Simultaneously, Mexico’s Ministry of Environment and Natural Resources (SEMARNAT) has embarked on initiatives employing drones to monitor and curb illegal logging activities across diverse regions of the country. These endeavors underscore the role of drones in bolstering both conservation efforts and responsible wood product manufacturing practices in Mexico.

Below are some drone application cases in wood product manufacturing industry.

In the USA, several wood product manufacturing companies have embraced drone technology to enhance their operations. Weyerhaeuser, one of the nation’s largest timber companies, employs drones for comprehensive forest inventory management and precise timber harvesting planning across its expansive land holdings. Simultaneously, PotlatchDeltic, a timber investment and real estate management firm, explores drone applications for tree health assessments and ongoing monitoring within its forests. Additionally, Domtar, a prominent paper and pulp manufacturer, utilizes drones for aerial surveys, providing valuable insights into the health of its tree plantations and the environmental impact of forestry operations on its supply chain. These examples underscore the transformative role of drones in optimizing wood product manufacturing practices while promoting sustainability in the industry.

In the United States, prominent players in the wood product manufacturing industry have harnessed the power of drone technology to optimize their operations. Weyerhaeuser, one of the nation’s largest timber companies, strategically employs drones for comprehensive forest inventory management and precise timber harvesting planning across its vast land holdings. Simultaneously, PotlatchDeltic, a timber investment and real estate management company, delves into drone applications for conducting tree health assessments and continuous monitoring within its forests. Additionally, Domtar, a leading paper and pulp manufacturer, utilizes drones for aerial surveys, providing invaluable insights into the well-being of its tree plantations and the environmental impact of forestry operations on its intricate supply chain. These compelling instances underscore the pivotal role drones play in enhancing wood product manufacturing while fostering sustainability within the industry.

In Mexico, the wood product manufacturing industry is experiencing a transformative impact through drone technology. Fibra MTY, a Mexican real estate investment trust, deploys drones for conducting aerial surveys and continuous monitoring of its forested properties, facilitating sustainable timber production practices. Simultaneously, SEMARNAT (the Mexican Ministry of Environment and Natural Resources) spearheads initiatives leveraging drones to vigilantly monitor and combat illegal logging activities across diverse regions of Mexico. These efforts underscore the invaluable role drones play in bolstering conservation initiatives and promoting responsible wood product manufacturing practices within the country.

In Europe, key players in the wood product manufacturing sector are harnessing drone technology to optimize their operations and promote sustainability. Södra, a Swedish forest cooperative, has undertaken projects utilizing drones for tasks ranging from forest inventory management and monitoring tree health to optimizing wood harvesting practices within its extensive forests. Meanwhile, Stora Enso, a major European pulp and paper manufacturer operating in Finland and Sweden, has embarked on drone initiatives to enhance forest management, including the monitoring and assessment of the sustainability of its wood supply chain. In neighboring Finland, the Finnish Forest Center employs drones to diligently monitor and combat the spread of forest pests and diseases, such as the spruce bark beetle, safeguarding the health of Finland’s vast forests, which are pivotal to the wood product manufacturing industry in the region. These endeavors exemplify the critical role of drone technology in advancing wood product manufacturing practices and environmental conservation efforts across Europe.

GAO RFID Systems & Hardware for Wood Product Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including wood product manufacturing.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including wood product manufacturing

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including wood product manufacturing:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including wood product manufacturing:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including wood product manufacturing:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including wood product manufacturing:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

In collaboration with its sister company GAO Tek Inc, a wide selection of high quality drones are offered:

The RFID systems by GAO are highly popular for clients in wood product manufacturing

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

In wood product manufacturing, a range of specialized equipment is employed to facilitate various aspects of the production process. These include table saws and band saws for cutting, jointers and planers for shaping and smoothing, lathes for turning, mortisers for joinery, and CNC routers for intricate designs. Additionally, edge banding machines, sanding equipment, dust collection systems, and spray booths aid in finishing. Clamps, gluing tools, panel saws, veneer presses, boring machines, dowel insertion machines, tenoners, lathe chucks, woodworking benches, and pneumatic tools further assist in ensuring precision, efficiency, and quality in wood product manufacturing. The specific equipment used can vary depending on the type of furniture being produced and the manufacturing processes employed.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for wood product manufacturing and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

- Services

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in wood product manufacturing have worked with to serve our joint customers:

- IBM Global Services

- Accenture

- Deloitte

- Cognizant

- Capgemini

- Wipro Technologies

- DXC Technology

- HCL Technologies

- Tata Consultancy Services (TCS)

- Infosys

- NTT Data

- Tech Mahindra

- Mindtree

- Hitachi Vantara

- CGI Group

- EPAM Systems

- NCR Corporation

- UST Global

- CACI International

- L&T Technology Services

GAO Has Served Wood Product Manufacturing Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in wood product manufacturing Industry to achieve success inThese include a strong emphasis on sustainable manufacturing practices, the integration of smart furniture with IoT technology, customization and personalization to meet consumer preferences, and the adoption of digital twin technology for design and prototyping. Circular economy principles are gaining traction, along with automation and robotics, 3D printing, augmented and virtual reality, and artificial intelligence for optimizing production processes. Additionally, supply chain resilience, mass timber construction, biomimicry, lean manufacturing, Industry 4.0, e-commerce expansion, collaborative design and manufacturing, zero-waste production strategies, and the use of sustainable materials and finishes are shaping the industry’s future.

GAO RFID Inc. has served many customers in wood product manufacturing, including its various divisions such as

- Lumber and Sawmill Products: This division involves the processing of logs into various types of lumber, such as softwood and hardwood boards, dimension lumber, and engineered wood products like plywood and oriented strand board (OSB).

- Engineered Wood Products: This sub-industry includes the manufacture of engineered wood products such as laminated veneer lumber (LVL), glue-laminated timber (glulam), and composite wood products like particleboard, MDF (medium-density fiberboard), and wood-plastic composites.

- Wooden Furniture Manufacturing: Companies in this division specialize in crafting wooden furniture, including residential and commercial furniture items like tables, chairs, cabinets, and bedroom sets.

- Wooden Cabinetry and Millwork: This sub-industry focuses on the production of wooden cabinets, countertops, and custom millwork for residential and commercial applications.

- Wood Flooring Manufacturing: Manufacturers in this division produce a variety of wood flooring products, including hardwood flooring, engineered wood flooring, and laminate flooring.

- Wooden Door and Window Manufacturing: Companies in this category specialize in the production of wooden doors, windows, frames, and related products for residential, commercial, and industrial use.

- Wooden Boat and Shipbuilding: This sub-industry involves the construction of wooden boats, ships, and maritime components, catering to both recreational and commercial marine sectors.

- Wooden Pallet and Container Manufacturing: Manufacturers in this division produce wooden pallets, crates, and containers used for shipping and storage of goods.

- Wooden Toy Manufacturing: Companies in this niche create wooden toys and games, often focusing on traditional and eco-friendly toy designs.

- Wooden Musical Instrument Manufacturing: This sub-industry includes the production of wooden musical instruments like guitars, violins, pianos, and percussion instruments.

- Wooden Dowels and Turnings: Manufacturers in this category specialize in producing wooden dowels, spindles, and turned components used in various applications, including furniture and cabinetry.

- Wooden Home Decor and Craft Items: Companies create a wide range of wooden home decor and craft products, including picture frames, wall art, and DIY craft kits.

- Wooden Building Components: This division includes the manufacturing of wooden building components like trusses, prefabricated wall panels, and structural wood products used in construction.

- Wood Preservation and Treatment: This sub-industry focuses on treating and preserving wood products to enhance their durability and resistance to decay, insects, and environmental factors.

- Woodworking Machinery and Equipment Manufacturing: Manufacturers in this niche produce machinery and equipment used in various woodworking processes, such as sawing, planing, and joinery.

GAO’s technologies enable its customers in “wood product manufacturing” to effectively track their workforces such as carpenters, furniture makers, cabinetmakers, assemblers, finishers, and machine operators, collaborate to create and assemble wooden furniture pieces. Wood turners specialize in lathe-based craftsmanship, while upholsterers add fabric or leather cushions. Quality control inspectors ensure the products meet standards, while production supervisors oversee operations. Maintenance technicians maintain machinery, and designers create blueprints. Specialists handle wood procurement, logistics, and customer service. These diverse roles collectively contribute to the production and delivery of high-quality wood product are actively track operational assets such as a variety of operational equipment is commonly used to streamline the production process. This equipment includes table saws for straight cuts, band saws for curved cuts, planers for smoothing and flattening, and jointers for creating flat edges. Other essential tools encompass routers, miter saws, drill presses, sanding machines, edge banders, veneer presses, dust collectors, clamps, finishing sprayers, CNC routers, doweling machines, lathes, mortising machines, boring machines, panel saws, and pneumatic staplers/nail guns. These machines and tools collectively enable the precise shaping, joining, and finishing of wood product components, contributing to the industry’s efficiency and quality standards.

Here are some of the leading companies in wood product manufacturing industry GAO has served:

- Ethan Allen Interiors Inc.

- La-Z-Boy Inc.

- Bassett Furniture Industries Inc.

- Rowe Furniture

- Flexsteel Industries Inc.

- Stanley Furniture Company Inc.

- Kincaid Furniture

- Norwalk Furniture

- Paula Deen Home

- Riverside Furniture Corporation

- Herman Miller

- Steelcase

- Broyhill Furniture

- Smith Brothers of Berne

- Craftmaster Furniture

- Best Home Furnishings

- Klaussner Furniture

- Hickorycraft Furniture

- American Leather

- Crate and Barrel

- DWR – Design Within Reach

- Ashley Furniture Industries

- Mitchell Gold + Bob Williams

- Joybird

- Room & Board

- Z Gallerie

- Norwalk Furniture

- The Sofa Company

You Are Invited to Contact Us!

If you interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com