Index

GAO Helps Customers Comply with Standards, Mandates & Regulations of Spring and Wire Product Manufacturing Industry

GAO’s Software Provides Easy Integration with API

Case Studies of RFID Applications

GAO RFID Systems & Hardware for Spring and Wire Product Manufacturing Industry

GAO makes efforts to satisfy customers

GAO Has Served Spring and Wire Product Manufacturing Industry

Overview

The Spring and Wire Product Manufacturing industry produces a diverse range of metal wire-based products, such as springs and wire forms, used in various applications across industries like automotive, aerospace, and construction. These products undergo precision manufacturing processes and are subject to quality standards. The industry is globally competitive, influenced by economic cycles, and driven by innovation and sustainability efforts.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in Spring and Wire Product Manufacturing Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as Wire Drawing Machines, Coiling Machines, Forming Machines, Heat Treatment Furnaces, Cutting Machines, Grinding Machines, Welding Machines, Testing and Inspection Equipment, Coating and Plating Equipment, Material Handling Equipment, Tooling and Dies, CNC Machinery, Safety Equipment, Maintenance Tools, Quality Control and Testing Instruments, Environmental Control Systems, Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) Software, Inventory Management Systems.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in Spring and Wire Product Manufacturing. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Spring and Wire Product Manufacturing Industry

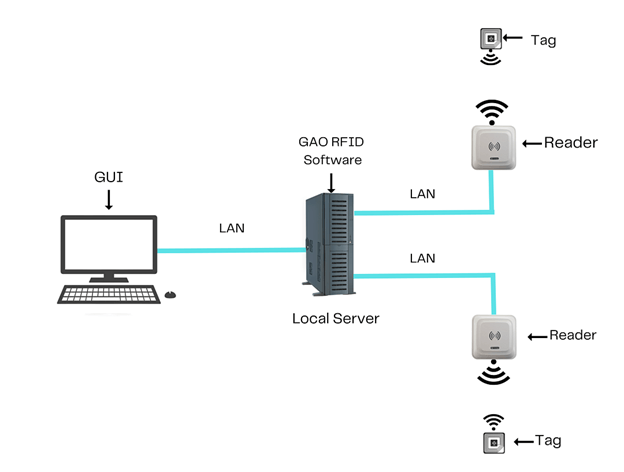

To satisfy its customers, GAO’s RFID or RFID Systems for Historical Sites Industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for sub-industry with its software running on a local server.

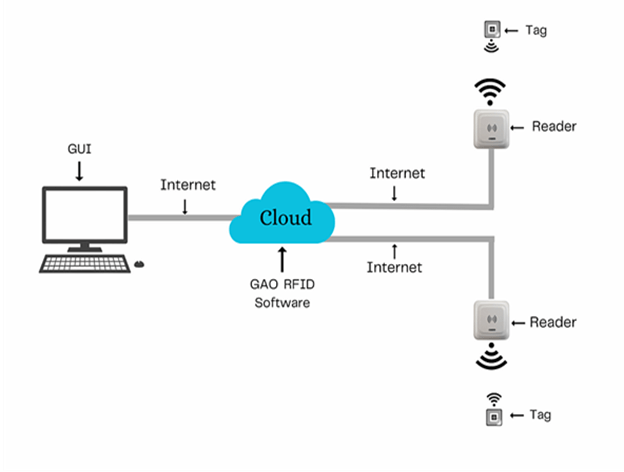

The above illustrates GAO system for Historical Sites Industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in Historical Sites industry:

- Visitor Access and Admission Control: RFID-enabled tickets or wristbands can streamline entry processes, reducing waiting times and enhancing security.

- Guided Tours: RFID tags in exhibits and points of interest can trigger audio guides or multimedia presentations on visitors’ devices, offering personalized and interactive tours.

- Interactive Exhibits: RFID-enabled interactive displays can provide detailed information when visitors interact with objects, encouraging engagement and learning.

- Augmented Reality (AR) Enhancements: Combining RFID with AR technology, visitors can access historical reconstructions, animations, and additional content related to artifacts.

- Artifact Tracking and Management: RFID tags can be attached to artifacts, enabling efficient inventory management, tracking, and preventing theft or loss.

- Conservation Monitoring: RFID-enabled sensors can help monitor temperature, humidity, and light levels to ensure optimal preservation conditions for delicate artifacts.

- Queue Management: RFID-based systems can manage visitor flows, reducing overcrowding and ensuring a smoother experience during peak times.

- Interactive Workshops and Activities: RFID tags can enable hands-on workshops and activities, providing visitors with interactive learning experiences.

- Personalized Experiences: RFID technology can facilitate personalized content delivery, tailoring information to visitors’ interests and preferences.

- Cultural Exchange and Language Translation: RFID-enabled devices can offer translations of exhibit information, enhancing accessibility for international visitors

- Digital Souvenirs: Visitors can use RFID-equipped devices to collect digital souvenirs, photos, or information during their visit.

- Event and Program Management: RFID can assist in managing events, workshops, and performances by tracking attendance and managing access to different areas.

- Feedback and Engagement: RFID systems can gather feedback from visitors, allowing historical sites to continually improve their offerings.

- Emergency Response: RFID-enabled systems can aid emergency response teams in identifying and locating visitors during evacuations.

- Educational Initiatives: RFID technology can support educational programs by tracking student participation and engagement in various activities.

- Membership and Loyalty Programs: RFID cards or devices can be used for membership identification and loyalty programs, offering special benefits to frequent visitors.

- Cafeteria and Gift Shop Transactions: RFID-based payment systems can streamline transactions in on-site amenities, improving convenience for visitors.

- Archaeological Excavation Management: RFID tags can be used to label and catalog artifacts during archaeological digs, improving the accuracy of data collection.

GAO’s drone technologies find the following applications in the Historical Sites industry:

- Smart Lighting: IoT-enabled lighting systems can adjust brightness and color temperature based on occupancy and time of day, enhancing the ambiance while conserving energy.

- Environmental Monitoring: IoT sensors can track temperature, humidity, air quality, and light levels to ensure optimal preservation conditions for artifacts and structures.

- Security and Surveillance: IoT cameras and sensors can provide real-time monitoring of historical sites, helping prevent vandalism, theft, or unauthorized access.

- Predictive Maintenance: IoT devices can monitor the structural integrity of buildings and monuments, predicting maintenance needs and preventing deterioration.

- Visitor Tracking and Analytics: IoT systems can analyze visitor movements to optimize exhibit layouts, understand traffic patterns, and improve the overall visitor experience.

- Energy Management: IoT-based systems can regulate heating, cooling, and other energy-consuming systems to minimize waste and reduce operating costs.

- Smart Signage: IoT-enabled signs can dynamically update information, direct visitors, and even provide translations based on user preferences.

- Audio Guides and Interpretive Content: IoT devices can provide location-based audio guides and multimedia content to enhance visitor engagement and education.

- Virtual Reality (VR) and Augmented Reality (AR) Enhancements: IoT can integrate with VR/AR applications, offering immersive experiences and historical reconstructions.

- Emergency Response Systems: IoT can aid in emergency response by providing real-time data on occupancy, guiding evacuations, and improving coordination.

- Asset Tracking: IoT-enabled tags can track the movement of artifacts, ensuring their location is known at all times and preventing loss or theft.

- Tourist Flow Management: IoT systems can monitor and manage visitor flows to prevent overcrowding and enhance the overall visitor experience.

- Cultural Heritage Preservation: IoT sensors can monitor the condition of artifacts, sculptures, and structures, alerting authorities to any changes that might require attention.

- Waste Management: IoT-enabled bins can monitor fill levels and optimize waste collection routes, reducing operational costs and environmental impact.

- Public Engagement: IoT can facilitate interactive displays, encourage user-generated content, and gather feedback to improve site offerings.

- Automated Audiovisual Presentations: IoT can trigger audiovisual presentations, lighting effects, or animations based on visitor proximity or scheduled events.

- Historical Data Collection: IoT devices can gather data about visitor interactions, preferences, and demographics, aiding in historical and sociocultural research.

- Remote Monitoring: IoT systems enable remote monitoring and management of historical sites, allowing staff to respond to issues quickly.

- Exhibit Conservation: IoT sensors can monitor factors like light exposure and temperature, alerting curators if conditions exceed safe thresholds.

- Interconnected Amenities: IoT can enable efficient management of amenities such as restrooms, cafes, and gift shops, improving convenience for visitors.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Spring and Wire Product Manufacturing

GAO RFID Inc. has helped many companies in Spring and Wire Product Manufacturing to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000 series

- ISO 15693

- EPC Gen2

- ISO 14443

- ISO 21481 (NFC)

- ISO 29167

- AIM Global Standards

- Bluetooth SIG (Special Interest Group.

- Bluetooth Core Specification

- Bluetooth 4.0

- Bluetooth 4.1, 4.2, and 5

- Bluetooth Profiles

- Bluetooth Mesh

- Bluetooth SIG Specifications

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- TLS (Transport Layer Security)

- IEEE 802.11 (Wi-Fi Standards)

- IEEE 802.15.4 (Low-Rate Wireless Personal Area Network Standards

US Government Regulations

- Occupational Safety and Health Administration (OSHA) Regulations

- Environmental Protection Agency (EPA) Regulations

- National Fire Protection Association (NFPA) Standards

- National Institute for Occupational Safety and Health (NIOSH) Regulations

- Department of Transportation (DOT) Regulations

- Federal Trade Commission (FTC) Regulations

- Consumer Product Safety Commission (CPSC) Regulations

- Federal Communications Commission (FCC) Regulations

- Department of Labor (DOL) Regulations

- Internal Revenue Service (IRS) Regulations

- S. Customs and Border Protection (CBP) Regulations

- Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) Regulations

Canadian Government Regulations

- Occupational Health and Safety Regulations

- Environmental Protection Regulations

- Transportation of Dangerous Goods Regulations

- Canada Consumer Product Safety Act

- Canadian Environmental Protection Act

- Competition Act

- Customs Tariff

- Income Tax Act

- Canadian Radio-television and Telecommunications Commission (CRTC) Regulations

- Export and Import Permits Act

- Controlled Goods Program

- Canadian Standards Association (CSA) Standards (voluntary standards)

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in Spring and Wire Product Manufacturing such as:

Personnel Management:

- HRIS (Human Resource Information System)

- Training and Certification Tracking

- Performance Management

- Safety Compliance

Equipment Management:

- Predictive Maintenance

- Asset Tracking

- Inventory Management

- Energy Management

Access Control:

- Biometric Access Control

- Access Logs and Auditing

- Visitor Management

Warehouse Management:

- Inventory Tracking

- Order Fulfillment

- Space Optimization

- Quality Control

Supply Chain Management:

- Supplier Relationship Management (SRM)

- Demand Forecasting

- Transportation Management

- Just-in-Time (JIT) Manufacturing

Other Applications:

- Compliance and Regulatory Tracking

- Quality Management Systems (QMS):

- Customer Relationship Management (CRM)

- Data Analytics and Business Intelligence

GAO has enabled its customers to make use of some of the leading software and cloud services in Spring and Wire Product Manufacturing industry. Below are some of popular software and cloud services in Spring and Wire Product Manufacturing:

Workday HCM, Oracle HCM Cloud, ADP Workforce Now, BambooHR, UltiPro, Kronos Workforce Central, Paylocity, Zenefits, Gusto, IBM Maximo, Infor EAM, Fiix, UpKeep, Asset Panda, eMaint, Maintenance Connection, MPulse, Hippo CMMS, Limble CMMS, BambooHR, Gusto, Zenefits, ADP Workforce Now, Workday, Paychex, Namely, Paycom, QuickBooks Payroll, Kronos Workforce Ready, IBM Maximo, Infor EAM, UpKeep, Fiix, Asset Panda, eMaint, Limble CMMS, ManagerPlus, MaintiMizer, MPulse, Honeywell Access Control, LenelS2 OnGuard, Brivo Access Control, AMAG Technology Symmetry, Paxton Access Control, RS2 Access Control, Kisi, Avigilon Access Control, Identiv, Gallagher Command Centre, Manhattan Associates WMS, Oracle WMS Cloud, HighJump Warehouse Management, JDA Warehouse Management, SAP Extended Warehouse Management (EWM), Infor CloudSuite WMS, Fishbowl Inventory.

GAO has worked with some of the leading technology companies in Spring and Wire Product Manufacturing to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in Spring and Wire Product Manufacturing:

IBM, Microsoft, Oracle, SAP, Salesforce, Cisco Systems, Hewlett Packard Enterprise (HPE), Dell Technologies, Accenture, Cognizant. Intel, NVIDIA, Texas Instruments, Analog Devices, Broadcom Inc., STMicroelectronics, Microchip Technology, NXP Semiconductors, Infineon Technologies, ON Semiconductor. Siemens, Rockwell Automation, ABB, Schneider Electric, Emerson Electric, Mitsubishi Electric, Omron Corporation, Yokogawa Electric, Honeywell, Fanuc.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in Spring and Wire Product Manufacturing industry:

- Murata ID Solutions is a company that provides RFID solutions for various industries, including Spring and Wire Product Manufacturing. One of their use cases is RFID-enabled inventory management for a leading manufacturer of springs and wire forms in the USA. The solution involved tagging each product with an RFID label and installing RFID readers at strategic points in the warehouse. The system enabled real-time visibility of the inventory levels, location, and status of each product, as well as automated data capture and reporting. The benefits of the solution included improved accuracy, efficiency, and productivity, as well as reduced labor costs, errors, and waste.

- Voipio et al. conducted a case study on the impact of RFID-enabled digital twin on the supply chain performance of a global manufacturing firm. A digital twin is a virtual representation of a physical object or system that can be used for simulation, analysis, and optimization. The case study involved implementing RFID technology to track and monitor the movement and condition of products and materials throughout the supply chain, from production to distribution. The data collected by the RFID system was used to create a digital twin of the supply chain, which enabled better visibility, control, and decision making.

- The results of the case study showed that the RFID-enabled digital twin provided significant benefits in terms of cost reduction, product availability improvement, and higher cognition tools.

Case Studies of IoT Applications

Below are some IoT application cases in Spring and Wire Product Manufacturing industry:

- Acme Wire Products is a company that specializes in custom wire forming, welding, and fabrication. They use IoT to monitor and control their production processes, such as wire cutting, bending, welding, and coating. They have installed sensors on their machines and equipment to collect data on parameters such as temperature, pressure, speed, and quality. They use a cloud-based platform to analyze the data and optimize their operations. They also use IoT to track their inventory and shipments, as well as to communicate with their customers and suppliers. By using IoT, Acme Wire Products has improved their efficiency, quality, and customer satisfaction.

- Spring Manufacturers Institute (SMI) is an association of companies that produce springs, wire forms, and metal stampings. They use IoT to provide training and education for their members, as well as to promote the industry. They have developed an IoT-based platform called SMI Smart Spring Network that connects spring manufacturers with customers, suppliers, and service providers. The platform allows spring manufacturers to showcase their capabilities and products, as well as to access market intelligence and best practices. The platform also enables customers to find and order springs from qualified suppliers, as well as to track their orders and deliveries. By using IoT, SMI has created a digital ecosystem that enhances the competitiveness and innovation of the spring industry

- MW Industries is a company that produces springs, fasteners, metal bellows, and other engineered components. They use IoT to improve their product development and testing processes, as well as to ensure compliance with industry standards and regulations. They have integrated sensors and actuators into their products to enable real-time data collection and feedback. They use a cloud-based platform to store and analyze the data, as well as to generate reports and insights.

- They also use IoT to monitor and control their manufacturing processes, such as heat treatment, coating, and testing. By using IoT, MW Industries has enhanced their product quality, performance, and reliability.

Case Studies of Drone Applications

Below are some drone application cases in Spring and Wire Product Manufacturing industry:

- Spring Manufacturers Institute is a trade association that represents the North American spring industry. They have developed a [Smart Spring Manufacturing] initiative that aims to leverage IoT and other technologies to improve the efficiency, quality, and profitability of spring manufacturing. Some of the benefits of this initiative include reducing scrap, increasing uptime, enhancing traceability, and optimizing production processes. The initiative also provides training, education, and resources for spring manufacturers to adopt IoT solutions.

- MW Industries is a leading manufacturer of springs, fasteners, metal bellows, and other precision-engineered components. They have implemented IoT solutions to monitor and control their production equipment, such as coiling machines, heat treatment furnaces, and testing machines. They use sensors, PLCs, and cloud-based software to collect and analyze data from their machines, which helps them optimize their performance, reduce downtime, and ensure quality standards. They also use IoT to enable remote access and support for their machines, which reduces maintenance costs and improves customer service.

- WireCo WorldGroup is a global leader in manufacturing wire rope, synthetic rope, specialty wire, and engineered products. They have deployed IoT solutions to enhance their operational efficiency, safety, and quality. They use sensors, RFID tags, and wireless networks to track and monitor their raw materials, finished products, and equipment throughout their supply chain. They also use IoT to automate their production processes, such as wire drawing, stranding, closing, and coating.

- They use cloud-based software to analyze the data from their IoT devices, which helps them improve their productivity, reduce waste, and ensure compliance.

Case Studies of Drone Applications

Below are some drone application cases in Spring and Wire Product Manufacturing industry:

- Drones equipped with cameras and sensors are used to conduct routine inspections of chemical manufacturing facilities. They can identify structural issues, equipment wear and tear, and potential hazards. This proactive approach helps prevent costly breakdowns and ensures regulatory compliance.

- Drones are employed to inspect chemical storage tanks, both aboveground and underground. They can capture images and data to assess the condition of tanks, detect leaks, and monitor corrosion levels. This enhances safety and reduces the risk of environmental incidents.

- Drones equipped with specialized sensors are used for environmental monitoring around chemical manufacturing plants. They can detect air and water pollution, emissions, and chemical leaks, providing real-time data to help maintain compliance with environmental regulations.

- Drones with RFID or barcode scanning capabilities are used to perform rapid inventory counts of chemical products stored in large warehouses or yards. This improves inventory accuracy and reduces the time and labor required for manual counts.

GAO RFID Systems & Hardware for Spring and Wire Product Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including apparel, piece goods, and notions merchant wholesalers.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

- BLE (Bluetooth Low Energy)

As well as versatile beacons with such important functions as temperature, humility, vibration, and panic button:

- GAO RFID Beacons

GAO’s BLE technology is suitable for many industries, including apparel, piece goods, and notions merchant wholesalers.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including apparel, piece goods, and notions merchant wholesalers:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including apparel, piece goods, and notions merchant wholesalers:

And an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including apparel, piece goods, and notions merchant wholesalers:

- high-frequency-13-56-mhz-rfid-readers

- high-frequency-134-khz-rfid-readers

- low-frequency-125-khz-rfid-readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including apparel, piece goods, and notions merchant wholesalers:

And antennas:

GAO also offers RFID printers:

Digital I/O adapters:

And relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- uhf-860-960-mhz-rfid-modules

- 13-56-mhz-high-frequency-rfid-modules

- 125-khz-low-frequency-rfid-modules

The RFID systems by GAO are highly popular for clients in apparel, piece goods, and notions merchant wholesalers:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include.

- RFID Tagging Systems: RFID tagging systems are used to attach RFID tags to apparel, piece goods, and notions. These tags contain unique identification information that can be read by RFID readers, enabling efficient inventory management and tracking.

- Barcode Scanners: Barcode scanners are commonly used in the apparel industry to scan barcodes on products, price tags, and shipping labels. They provide accurate and fast data capture, facilitating inventory control, pricing, and order processing.

- Handheld Mobile Devices: Handheld mobile devices such as smartphones or tablets equipped with inventory management software are used by apparel wholesalers for on-the-go inventory tracking, order processing, and communication with suppliers and customers.

- Point of Sale (POS) Systems: POS systems are essential equipment for apparel wholesalers. These systems include hardware like cash registers, barcode scanners, and receipt printers, along with software that enables sales transactions, inventory management, and customer tracking.

- Shelving and Racking Systems: Shelving and racking systems are used to organize and store apparel, piece goods, and notions in warehouses and distribution centers. They provide efficient space utilization and easy access to products for picking and packing.

- Conveyor Systems: Conveyor systems are used to transport apparel items, piece goods, and notions within warehouses and distribution centers. They automate the movement of products, reducing manual handling and improving operational efficiency.

People or workers tracking system:

- PERSONNEL TRACKING SOFTWARE

Physical asset or operational equipment tracking system:

- ASSET TRACKING SOFTWARE

Personnel or people access control system:

- ACCESS CONTROL SOFTWARE

Parking or vehicle control system:

- PARKING CONTROL SOFTWARE

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in Historical Sites industry we have worked with to serve our joint customers:

- Industry Associations

- Networking

- Online Research

- Accenture

- Deloitte

- Capgemini

- Cognizant

- IBM Global Business Services

- PwC (PricewaterhouseCoopers)

- EY (Ernst & Young)

- Infosys

- Wipro

- Tata Consultancy Services (TCS)

- Compugen

- Long View Systems

- Softchoice

- Sierra Systems

- Scalar

- CGI

- ProServeIT

- OnX Canada

- Inlanta Technologies

- i. Systems

- Neoris

- Softtek

- KIO Networks

- UST Global

- Grupo Carso

- Telvista

- Grupo Quimmco

- Megacable

- Origo Solutions

- Binbit

- Atos

- Sopra Steria

- Devoteam

- TietoEVRY

- NTT DATA

- DXC Technology

- Wipro

GAO Has Served Spring and Wire Product Manufacturing Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in Spring and Wire Product Manufacturing Industry to achieve success in Industry 4.0, Digital Transformation, IoT (Internet of Things), Predictive Maintenance, Wireless Technologies, Sustainability, Lean Manufacturing, Supply Chain Optimization, Customization, Quality Control. Smart Factory, Big Data Analytics, Digital Twin, Additive Manufacturing, Blockchain, AI (Artificial Intelligence), Robotics, Cybersecurity, Reshoring, SME (Subject Matter Expert).

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in Spring and Wire Product Manufacturing, including many in its various divisions such as:

- Compression Springs: Manufacturers specialize in the production of compression springs, which are designed to resist compression forces and return to their original length when the force is removed. These springs are commonly used in automotive, aerospace, and industrial applications.

- Extension Springs: Companies that focus on manufacturing extension springs, which expand or extend when a pulling force is applied. They are used in a wide range of applications, including garage doors and farm machinery.

- Torsion Springs: Torsion spring manufacturers create springs that exert rotational or twisting forces. They are often used in applications like door hinges, clothing pins, and various machinery.

- Wire Forms: Manufacturers of wire forms produce custom-shaped wire products used in a variety of industries, such as automotive, electronics, and construction.

- Coil Springs: This segment includes companies that produce various types of coil springs, which can be compression, extension, or torsion springs. Coil springs find applications in diverse industries, from furniture to heavy machinery.

- Precision Springs: Precision spring manufacturers specialize in producing springs with extremely tight tolerances and high precision. These springs are often used in critical applications like medical devices and aerospace.

- Flat Springs: Companies that manufacture flat springs, which are typically thin, flat strips of material that store or release energy when bent. These are used in applications like electronics and automotive components.

- Custom Spring Manufacturing: Specialized manufacturers that create custom-designed springs for specific applications, tailored to the unique requirements of their customers.

- Wire Products for Construction: Some companies in this industry focus on wire products used in construction, such as reinforcement bars (rebar) and mesh.

- Wire Products for Furniture: Manufacturers that specialize in wire products used in the furniture industry, including springs and wire components for chairs and sofas.

- Automotive Springs: Companies that produce springs specifically for the automotive industry, including suspension springs, seat springs, and valve springs.

- Medical Springs: Manufacturers that create springs for medical devices, such as surgical instruments and implantable devices.

GAO’s technologies enable its customers in “Spring and Wire Product Manufacturing” to effectively track their workforces such as Wire Diameter, Coiling, Wire Forming, Tempering, Draw Length, Tensile Strength, Elasticity, Load Capacity, Pitch, Hot Coiling, Cold Coiling, Annealing, Spring Rate, Winding Direction, Mandrel, Pitch Diameter, Surface Finish, Wire Cutter, Quality Control, Material Composition, Wire Drawing, Wire Lubrication, Welding, Safety Protocols, Inventory Management and effectively track operational assets such as Wire Drawing Machine, Coiling Machine, Heat Treatment Furnace, CNC Spring Forming Machine, Wire Bending Machine, Coil Spring Grinding Machine, Testing Equipment, Coating and Plating Equipment, Welding Machine, Packaging Machinery, Quality Control Tools, Wire Lubrication System, Material Handling Equipment, Die Sets and Tooling, Robotics and Automation, Environmental Control Equipment, Ultrasonic Cleaning Machine, Material Handling Carts and Racks, Waste Management Equipment.

Here are some of the leading companies in Spring and Wire Product Manufacturing industry GAO has served:

- Associated Spring Raymond

- MW Industries, Inc.

- Ace Wire Spring & Form Co., Inc.

- Stanley Spring and Stamping Corporation

- Newcomb Spring Corp.

- Mid-West Spring & Stamping

- Pontotoc Spring

- Mid-West Wire Products

- Industrial Spring Corporation

- Leeco Spring International

- Peninsula Spring Corporation

- Acxess Spring

- Diamond Wire Spring Company

- Hardware Products Company

- Elyria Spring & Stamping

- Plymouth Spring Company, Inc.

- Alabama Wire, Inc.

- Associated Spring Raymond Canada

- Alabama Spring Corporation

- Ressorts Liberté Springs Inc.

- Tennessee Spring & Metal

- Peterson Spring

- Springs & Things Inc

- Rassini

- Les Ressorts LR Spring Inc.

- Resortes Y Formas

- Novaspring

- European Springs & Pressings Ltd