The tunnel construction industry specializes in the excavation and construction of tunnels for transportation infrastructure, such as trains or vehicles. This involves using various methods, including tunnel boring or drill and blast, to create a secure and safe underground passage. The industry also involves installing ventilation, lighting, and other necessary systems to ensure efficient and safe transportation through the tunnels.

GAO RFID Inc., one of the global top 10 RFID leaders, is based in the cities of New York and Toronto and it has deployed many RFID, BLE and IoT projects in tunnel construction.

GAO RFID Systems & Hardware for Tunnel Construction

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including tunnel construction.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for all kinds of industries, including tunnel construction.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including tunnel construction:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including tunnel construction:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including tunnel construction:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including tunnel construction:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in tunnel construction:

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

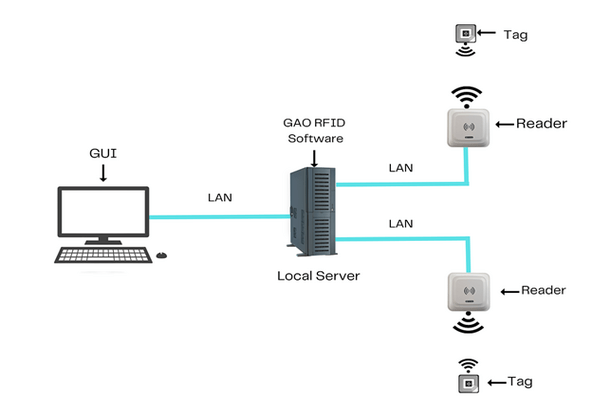

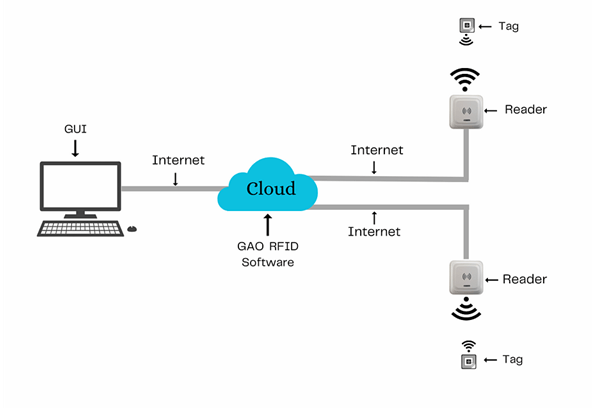

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

GAO offers free samples of its RFID tags, labels, badges, and wristbands.

GAO offers a free trial for all of its software available.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Tunnel Construction

Applications & Benefits of applying RFID to the tunnel construction

- Improved efficiency: GAO RFID tags improve efficiency by providing better inventory management and efficient project planning by tracking PVC pipes, steel bolts, steel arches, excavators and pumps, etc. as they move through the construction process.

- Cost optimization: Our RFID solutions can help keep track of concrete, shotcrete, asphalt and fiberglass, tunnel boring machines and road-headers, etc. you have onsite and the quantities used in order to schedule deliveries from off-site storage or your suppliers thus reducing labor costs.

- Improved inventory management: By providing real-time data on inventory levels and locations of grout, bentonite and geotextile, etc., our RFID solutions prevent both overstocking and stock shortages.

Applications & Benefits of applying BLE technology to the tunnel construction

- Long-range tracking: GAO BLE products have a longer range of up to 300 meters, making it ideal for tracking the location of workers and equipment like tunnel boring machine, shaft, etc., providing accurate and up-to-date information to project managers and other stakeholder.

- Real-time asset tracking: Due to the relatively small size of GAO BLE solutions it can enable real-time tracking of the location and movement of materials and equipment such as asphalt, steel, locomotives, ventilation fans, etc., allowing for better inventory management and more efficient project planning.

- Access Control: GAO BLE beacons wirelessly transit credentials so that workers and labors can be verified and granted/restricted access by our gateways. Our access control system pertains to the verification of workers required for them to conduct safe work on a tunnel construction site.

Applications & Benefits of applying combination of RFID and drones to the tunnel construction

- Rapid data collection: Drones equipped with GAO RFID solutions can quickly and easily collect data from a large area, including areas that are difficult to access by foot or by vehicle.

- Improved safety: By using drones to collect RFID data, workers do not have to enter hazardous or hard-to-reach areas, reducing the risk of accidents and injuries.

- Surveillance: Drones can also be equipped with cameras to provide a bird’s eye view of the site, allowing managers to identify potential safety hazards before they become a problem.

Applications & Benefits of applying combination of RFID and IoT to the tunnel construction

- Monitoring accurate environmental factors: IoT sensors can be combined with RFID to monitor in real-time a wide range of environmental factors, including temperature, humidity, and vibrations.

- Predictive maintenance: IoT sensors in the RFID tags can detect vibrations or other hazardous conditions, alerting managers to potential safety issues before they cause an accident or injury.

- Enhanced data analysis: IoT-enabled RFID tags can collect a wide range of data and by using advanced data analytics tools, your construction company can gain valuable insights into your operations and identify areas for improvement.

GAO Helps Customers Comply with Standards, Mandates & Regulations

GAO RFID Inc. has helped many companies in tunnel construction to deploy RFID systems and to ensure such deployments complying with the applicable industry standards, mandates and regulations:

- Federal Railroad Administration (FRA): In the United States, the Federal Railroad Administration (FRA) has proposed a rule that would require the use of RFID tags to identify rail cars carrying hazardous materials.

- Federal Transit Administration (FTA): The FTA is responsible for overseeing public transportation, including tunnels for transit systems such as subways and light rail.

- Occupational Safety and Health Administration (OSHA): OSHA provides regulations related to the safety of workers during tunnel construction, including the use of personal protective equipment (PPE), ventilation systems, and hazardous material handling.

- American Society of Civil Engineers (ASCE): The ASCE provides guidelines and standards related to the design, construction, and maintenance of tunnels for transportation infrastructure, including those for road and rail tunnels.

- Transport Canada (TC): Transport Canada is the federal agency that provides guidelines and regulations related to the construction and operation of tunnels for transportation infrastructure.

- Canadian Standards Association (CSA): The CSA is a non-profit organization providing guidelines and standards related to the design, construction, and operation of tunnels for transportation infrastructure.

GAO Software Provides API

GAO’s popular RFID software such as personnel tracking, asset tracking and access control system offers a free trial and offers an API to each of the common software for tunnel construction:

Personnel Management

- HR Management System: It includes recruitment, hiring, training, and scheduling of workers, and management of their performance, safety, and well-being.

- Project Management System: It involves setting timelines, budgets, and milestones, and ensuring compliance with regulatory requirements.

- Safety Management System: This involves management of safety and environmental risks, providing safety training and protective equipment.

Equipment Management

- Equipment Maintenance System: It includes maintenance, and repair of specialized tunneling equipment such as tunnel boring machines (TBM), drills, trucks, and other machinery.

- Asset Management System: It performs the management of equipment inventories, maintenance records, and depreciation schedules.

Supply Chain Management

- Procurement Management System: This involves the management of the complete procurement process.

- Inventory Management System: It performs the management of inventories of supplies and materials

Other Application Software

- Building Information Modeling (BIM) Software: It is a software used to help optimize the designing process for construction.

- Contract Management System: Such software stores and manages all contracts.

- RFID System: This system uses radio waves to identify people and objects.

Case Studies of GAO RFID Applications

One Case Study of RFID application in the tunnel construction is the East Side Access project in New York City. This project involves building a new underground railway connection between the Long Island Rail Road and Grand Central Terminal. RFID tags were used to track the location of tunnel-boring machines (TBMs) as they excavated the tunnels for this project. By using RFID technology, the project team was able to track the progress of the TBMs in real-time and monitor their exact locations. This allowed the team to adjust their construction plans as needed and ensure that the TBMs were on schedule and on the correct path.

Another case study about the application of RFID technology in tunnel construction is the Alaskan Way Viaduct Replacement Tunnel project in Seattle, Washington. During the construction of the tunnel, RFID tags were used to track the location of construction equipment and materials. The tags were read by RFID readers installed throughout the tunnel, providing real-time information on the location and movement of each tagged item. Thus ensuring that they were in the correct location at the right time.

GAO Has Served Tunnel Construction Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in tunnel construction, including its various divisions such as:

- Mining and drilling: This involves the excavation of rock or soil using heavy machinery and specialized drilling equipment.

- Shotcreting and concrete lining: It is the process of spraying concrete onto the walls and ceilings of the tunnel using a high-pressure hose.

- Waterproofing: This involves the installation of a waterproof membrane or coating on the tunnel walls to prevent water infiltration.

- Ventilation: This involves the installation of specialized fans and ductwork.

- Electrical and mechanical systems: This includes lighting, communication systems, fire suppression systems, and HVAC (heating, ventilation, and air conditioning) systems.

Here are some of the leading companies for tunnel construction in the United States:

Some of the leading companies for tunnel construction in Canada: