Overview

UAVs are used for a multitude of applications, including surveillance, reconnaissance, search and rescue, cargo delivery, photography and videography, agriculture, infrastructure inspection, environmental monitoring, and more. Their versatility has driven market growth. The industry is typically divided into two main segments: military and defense UAVs and civilian/commercial UAVs. Each segment has its own set of manufacturers, regulations, and customer bases. The UAV manufacturing industry features both established aerospace companies and newer startups. UAV technology continues to evolve rapidly, with advancements in materials, propulsion systems, communication technologies, and autonomous navigation capabilities. This has led to improved performance, longer flight durations, and increased payload capacities. The industry operates under a complex set of regulations that vary by country. These regulations cover aspects such as safety, privacy, airspace integration, and licensing. Compliance with regulations is a significant challenge for manufacturers and operators.

The UAV manufacturing industry has experienced significant growth due to increased demand from various sectors. This growth is driven by the cost-effectiveness, efficiency, and safety benefits that UAVs offer for tasks that were traditionally performed by manned aircraft or on the ground. Despite its growth, the industry faces challenges such as cyber security threats, public perception and privacy concerns, and the need for improved safety measures. Additionally, competition in the industry is fierce, with many companies vying for market share. The UAV manufacturing industry is a global market, with companies from various countries contributing to its growth. China, the United States, Israel, and Europe are among the leading regions in UAV manufacturing. Companies in this industry invest heavily in research and development to stay competitive and innovate. They aim to create UAVs that are more reliable, capable, and adaptable to a wide range of applications. As the industry grows, there is a growing emphasis on developing environmentally friendly UAVs, with reduced emissions and noise levels.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in unmanned aerial vehicle (UAV) manufacturing industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as: CNC Machines, 3D Printers, Composites Fabrication Equipment, Robotic Welding Machines, Avionics Testing Tools, CNC Routers, Laser Cutting Machines, Materials Testing Machines, Ultrasonic Testing Devices, Thermal Imaging Cameras, Environmental Test Chambers, Non-destructive Testing (NDT) Equipment, Surface Finishing Tools, Inspection Drones, Electrical Testing Equipment, Radio Frequency (RF) Testing Instruments, Fiber Placement Machines, Hydraulic Presses, Radio Communication Equipment, RFID Scanners, Barcode Scanners, Assembly Line Equipment, Calibration Tools, CNC Machining Centers, Soldering Stations, Paint Booths, Pneumatic Tools, Material Handling Equipment, Quality Control Instruments, Safety Equipment.

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S. and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC) and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, as well as its IoT and drone technologies, have been successfully deployed for unmanned aerial vehicle (UAV) manufacturing industry. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Unmanned Aerial Vehicle (UAV) Manufacturing Industry

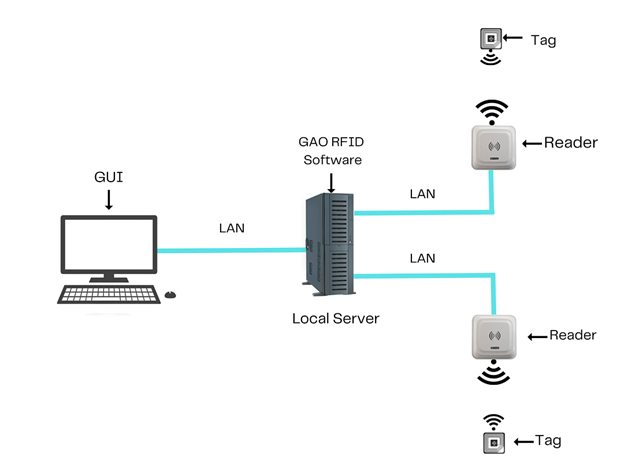

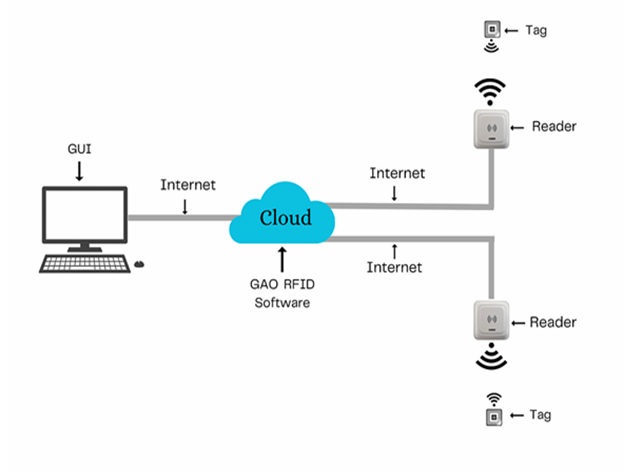

To satisfy its customers, GAO’s RFID or RFID Systems for unmanned aerial vehicle (UAV) manufacturing industry are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, CloudFlare, Linode and Rackspace. The above illustrates GAO system for unmanned aerial vehicle (UAV) manufacturing industry with its software running on a local server.

The above illustrates GAO system for unmanned aerial vehicle (UAV) manufacturing industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in unmanned aerial vehicle (UAV) manufacturing industry:

- Inventory Management: RFID tags can be attached to components and parts, allowing manufacturers to track the availability and location of inventory in real-time. This helps in streamlining the supply chain and ensuring that required parts are always on hand.

- Asset Tracking: UAV manufacturers can use RFID to track the movement and usage of critical assets, such as tools, machinery, and test equipment, ensuring they are where they need to be when needed.

- Work-in-Progress (WIP) Tracking: RFID tags on UAV components and sub-assemblies can monitor their progress on the production line. This enables real-time visibility into the manufacturing process and helps manage production schedules more efficiently.

- Quality Control: RFID can be used to link inspection data with individual components or units, ensuring quality control processes are adhered to and providing a traceable record of quality assurance.

- Tool Management: RFID-enabled tool tracking systems help ensure that the right tools are used for specific tasks and that they are calibrated and maintained properly. This reduces errors and increases worker safety.

- Maintenance and Servicing: RFID tags on UAVs can store maintenance history and service schedules. This helps maintenance teams keep track of when UAVs need servicing, minimizing downtime and ensuring safety.

- Access Control: RFID cards or badges can control access to restricted areas within UAV manufacturing facilities, ensuring security and safety.

- Counterfeit Prevention: RFID tags can be embedded within components or parts to help detect counterfeit products. This is especially important in the UAV industry, where safety and reliability are paramount.

- Supply Chain Visibility: UAV manufacturers can use RFID to monitor the movement of components and materials throughout the supply chain, improving overall visibility and reducing the risk of lost or delayed shipments.

- Data Collection and Analysis: RFID systems collect a wealth of data that can be analyzed to identify bottlenecks, optimize processes, and improve overall efficiency in manufacturing and logistics.

- Warranty Tracking: Manufacturers can use RFID to associate UAVs with their warranties, making it easier to track and manage warranty claims and services.

- Employee Safety: RFID badges or wearables can enhance worker safety by monitoring their locations and alerting management to potential safety concerns in real-time.

- Emergency Response: In the event of an emergency or safety issue, RFID technology can help locate personnel quickly and efficiently.

- Supplier Management: RFID technology can be used to monitor the performance and delivery schedules of suppliers, helping manufacturers make informed decisions about their supply chain partners.

GAO’s drone technologies find the following applications in the unmanned aerial vehicle (UAV) manufacturing industry:

- Site Surveying: Drones equipped with high-resolution cameras and LiDAR sensors can conduct site surveys for potential manufacturing facilities, providing detailed topographical and geographical data for site selection.

- Facility Design and Planning: UAVs can capture aerial imagery and 3D maps of the manufacturing site, aiding in facility design and layout planning for optimized workflows and safety.

- Quality Control: Drones can inspect UAV components, airframes, and manufacturing equipment with high-resolution cameras and thermal imaging, identifying defects and ensuring quality standards are met.

- Inventory Management: Drones with RFID or barcode scanning capabilities can conduct aerial inventory checks, helping manufacturers keep track of parts, materials, and equipment in real-time.

- Supply Chain Monitoring: UAVs can monitor the movement and transport of materials and components along the supply chain, ensuring timely deliveries and reducing the risk of disruptions.

- Maintenance and Repairs: Drones equipped with cameras and sensors can conduct visual inspections of UAVs, allowing maintenance teams to identify issues, plan repairs, and ensure airworthiness.

- Safety Inspections: Drones can perform safety inspections of manufacturing facilities, checking for potential hazards, compliance with safety regulations, and emergency response planning.

- Environmental Monitoring: UAVs can be used to monitor environmental factors, such as air quality, temperature, and humidity within manufacturing facilities to ensure optimal working conditions for personnel and machinery.

- Training and Simulation: Drones can be used for training purposes, simulating flight conditions and testing procedures for UAV operators and maintenance personnel.

- Security Surveillance: Drones equipped with cameras and sensors can enhance security by conducting aerial surveillance of manufacturing sites, detecting unauthorized access and potential security breaches.

- Material Handling and Transport: Drones can assist in moving lightweight materials and components within the manufacturing facility, reducing manual labor and improving efficiency.

- Prototype Testing: UAVs can carry prototype UAVs for flight testing, allowing engineers to collect data on aerodynamics, stability, and performance.

- Data Collection and Analysis: Drones can gather data during manufacturing processes, such as temperature and pressure readings, which can be used for process optimization and quality control.

- Documentation and Reporting: Drones can automatically generate reports and documentation, including photos and videos, to maintain a detailed record of manufacturing and inspection activities.

- Emergency Response: In the event of accidents or emergencies within the manufacturing facility, drones can quickly survey the area, locate personnel, and provide situational awareness to emergency responders.

- Marketing and Promotion: Drones can capture captivating aerial footage and images of UAV manufacturing processes, which can be used for marketing and promotional materials.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the unmanned aerial vehicle (UAV) manufacturing industry:

- Asset Tracking: IoT sensors and RFID tags can track the location and condition of UAV components, parts, and tools in real-time, facilitating inventory management and reducing the risk of loss.

- Predictive Maintenance: IoT sensors on manufacturing equipment and UAVs collect data on usage and performance, allowing for predictive maintenance scheduling to prevent unexpected breakdowns and minimize downtime.

- Quality Control: IoT sensors can monitor the manufacturing process, measuring parameters like temperature, humidity, and pressure, to ensure consistency and quality in the production of UAV components.

- Energy Efficiency: IoT-connected devices can optimize energy usage within manufacturing facilities, reducing operational costs and environmental impact.

- Remote Monitoring: IoT-enabled cameras and sensors on the manufacturing floor allow for remote monitoring of production processes and worker safety, reducing the need for physical presence.

- Supply Chain Visibility: IoT provides real-time visibility into the movement of materials and components along the supply chain, ensuring timely deliveries and reducing inventory holding costs.

- Equipment Health Monitoring: IoT sensors can monitor the health of manufacturing machinery, detecting anomalies and wear-and-tear, and triggering maintenance alerts.

- Environmental Monitoring: IoT sensors can track environmental conditions within manufacturing facilities, ensuring compliance with safety and regulatory standards, such as air quality monitoring for worker safety.

- Production Line Optimization: IoT data analytics can optimize production line efficiency by analyzing data from various sensors to identify bottlenecks and inefficiencies.

- Worker Safety: Wearable IoT devices, such as smart helmets and vests, can monitor worker safety by tracking their location, vital signs, and exposure to hazardous conditions.

- Energy Management: IoT systems can optimize lighting, heating, and cooling systems in manufacturing facilities, reducing energy consumption and costs.

- Robotic Process Automation: IoT-enabled robots and autonomous vehicles can streamline material handling and transport, reducing labor costs and improving accuracy.

- Remote Testing and Calibration: IoT-connected UAVs can undergo remote testing and calibration processes, reducing the need for physical presence during these procedures.

- Product Lifecycle Management: IoT helps in tracking the entire product lifecycle of UAVs, from design and manufacturing to maintenance and disposal, ensuring traceability and compliance.

- Security: IoT devices can enhance security measures within manufacturing facilities, including access control, surveillance, and intrusion detection systems.

- Data Analytics: IoT-generated data can be analyzed to gain insights into production processes, enabling continuous improvement and optimization.

- Regulatory Compliance: IoT data can be used to ensure compliance with industry and environmental regulations, reducing the risk of

GAO Helps Customers Comply with Standards, Mandates & Regulations of Unmanned Aerial Vehicle (UAV) Manufacturing Industry

GAO RFID Inc. has helped many companies in unmanned aerial vehicle (UAV) manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000 series – RFID air interface standards

- EPCglobal Gen2 – RFID standard for passive UHF tags

- ISO/IEC 14443 – RFID for contactless smart cards

- ISO/IEC 15693 – RFID for vicinity cards

- ATA Spec 2000 – Aviation industry standard for RFID use

- SAE AS5678 – Aerospace standard for RFID implementation

- Bluetooth SIG (Special Interest Group) – Oversees Bluetooth technology standards

- Bluetooth 4.0 and later – BLE standards for low-power wireless communication

- IEEE 802.15.1 – Standard for Bluetooth wireless technology

- IEEE 802.11 – Wi-Fi standards used in IoT devices

- MQTT (Message Queuing Telemetry Transport) – IoT messaging protocol

- CoAP (Constrained Application Protocol) – IoT protocol for resource-constrained devices

- OPC UA (Open Platform Communications Unified Architecture) – Industrial IoT standard for data exchange

- OMA LWM2M (Open Mobile Alliance Lightweight M2M) – IoT device management standard

- Zigbee Alliance – Organization overseeing Zigbee standards for IoT

- LoRa Alliance – Organization managing LoRaWAN IoT standards.

- FAA Part 107 – U.S. Federal Aviation Administration regulations for small drones

- Transport Canada’s RPAS Regulations – Canadian regulations for UAVs

- EASA Regulations – European Union Aviation Safety Agency regulations for drones

- ICAO RPAS Manual – International Civil Aviation Organization guidelines for UAVs

- ASTM International F38 Committee – Standards for unmanned aircraft systems

- ISO 21384 – International standard for drone identification and tracking

- ANSI/UL 3030 – Standard for safety of UAV systems

- SAE AS6971 – Standard for counter-UAS (Counter-Unmanned Aircraft Systems)

- RTCA DO-178C – Software considerations for airborne systems (applicable to drone software)

- RTCA DO-254 – Design assurance guidance for airborne electronic hardware (applicable to drone electronics

Government Regulations

- Part 107 (14 CFR Part 107)

- Section 333 Exemption (now replaced by Part 107)

- Part 21 (14 CFR Part 21)

- Part 27 (14 CFR Part 27)

- Part 29 (14 CFR Part 29)

- Part 91 (14 CFR Part 91)

- Part 135 (14 CFR Part 135)

- Export Administration Regulations (EAR)

- International Traffic in Arms Regulations (ITAR)

- Federal Aviation Regulations (FARs)

- Federal Communications Commission (FCC) Regulations

- National Telecommunications and Information Administration (NTIA) Guidelines

- National Institute of Standards and Technology (NIST) Standards

- National Aeronautics and Space Administration (NASA) Guidelines

- National Oceanic and Atmospheric Administration (NOAA) Policies

- Department of Defense (DoD) Directives and Instructions

- Environmental Protection Agency (EPA) Regulations

- Occupational Safety and Health Administration (OSHA) Standards

- Federal Emergency Management Agency (FEMA) Rules

- National Transportation Safety Board (NTSB) Recommendations

Canadian Government Regulations

- Canadian Aviation Regulations (CARs)

- Transport Canada’s Remotely Piloted Aircraft Systems (RPAS) Regulations

- Transport Canada’s SFOC (Special Flight Operations Certificate) Application Process

- Transport Canada’s Pilot Certification Requirements

- Transport Canada’s Drone Safety Awareness Test

- Transport Canada’s No Drone Zones and Restricted Airspaces

- Transport Canada’s Drone Registration Requirements

- Transport Canada’s UAV Operating Rules

- Radio Equipment Standards and Specifications (RESS)

- Industry Canada’s Spectrum Management and Licensing Requirements

- Privacy Laws and Regulations (various provincial and federal)

- Environmental Regulations (various provincial and federal)

- Export Controls (Global Affairs Canada)

- Workplace Health and Safety Regulations (various provincial and federal)

- National Research Council of Canada (NRC) UAV Research and Standards

- Canadian Radio-television and Telecommunications Commission (CRTC) Regulations

- National Energy Board (NEB) Regulations

- Canadian Space Agency (CSA) Guidelines

- Competition Bureau Canada Regulations

- Innovation, Science, and Industry Canada Regulations

GAO’s Software Provides API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in unmanned aerial vehicle (UAV) manufacturing industry such as:

Personnel Management:

- Employee Attendance Tracking

- Worker Safety Monitoring

- Training and Certification Management

- Human Resources Management

- Workforce Scheduling and Rostering

Equipment Management:

- Maintenance and Calibration Scheduling

- Equipment Health Monitoring

- Tool Inventory Management

- Equipment Utilization Optimization

Access Control:

- Secure Data Access Control

- Visitor Management

- Security Surveillance and Monitoring

Warehouse Management:

- RFID-Based Inventory Management

- Order Picking and Packing Optimization

- Storage Optimization

- Material Handling Automation

Supply Chain Management:

- Real-time Shipment Tracking

- Demand Forecasting

- Procurement and Supplier Quality Assurance

- Customs Compliance and Documentation

Other Applications:

- Defect Detection and Reporting

- Non-Destructive Testing (NDT)

- Quality Assurance Documentation

- Compliance and Regulatory Reporting

- Hazardous Material Handling and Monitoring

- Emission Monitoring

- Environmental Compliance Reporting

- Sustainability and Green Manufacturing Initiatives

- Renewable Energy Integration

- Reporting and Dashboards for Performance Tracking

- Predictive Analytics for Maintenance and Production Optimization

- Cybersecurity Auditing and Compliance

- Data Privacy Compliance (e.g., GDPR, CCPA)

- Occupational Safety and Health Compliance (OSHA)

- Environmental and Emissions Compliance

- Export Control Compliance (ITAR, EAR)

- Public Relations and Brand Promotion

- Customer Engagement and Education

- Design Iteration and Improvement

- Materials Research and Development

GAO has enabled its customers to make use of some of the leading software and cloud services in unmanned aerial vehicle (UAV) manufacturing industry. Below are some of popular software and cloud services in unmanned aerial vehicle (UAV) manufacturing industry:

SAP SuccessFactors, Oracle HCM Cloud, Workday HCM, eMaint, Maintenance Connection, HID Global, LenelS2, WMS by Oracle, Manhattan Associates, SAP Integrated Business Planning (IBP), Kinaxis RapidResponse, Oracle SCM Cloud.

GAO has worked with some of the leading technology companies in unmanned aerial vehicle (UAV) manufacturing industry in to provide integrated its RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in unmanned aerial vehicle (UAV) manufacturing industry:

Northrop Grumman Corporation, General Atomics Aeronautical Systems, Inc. (GA-ASI), Lockheed Martin, Elbit Systems, AeroVironment, Inc., Parrot, DJI (Dà-Jiāng Innovations), Kratos Defense & Security Solutions, FLIR Systems, Raytheon Technologies, Insitu Inc., Textron Inc., PrecisionHawk, Impossible Aerospace, Silent Falcon UAS Technologies, Quantum Systems, Swift Engineering, Parallax Advanced Research, MartinUAV.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases in unmanned aerial vehicle (UAV) manufacturing industry.

RFID tags can be used to track and manage UAV components, tools, and equipment in manufacturing facilities, ensuring efficient inventory management.

RFID technology can monitor the movement of UAV components along the production line, helping to optimize assembly processes and ensure quality control.

RFID tags can be attached to critical components or parts, allowing for real-time quality checks and traceability throughout the manufacturing process.

RFID tags on UAVs in production can provide visibility into the progress of each unit, helping to manage production schedules and identify bottlenecks.

RFID can be used to track the movement of materials and components along the UAV supply chain, from suppliers to manufacturers, ensuring timely deliveries and reducing inventory holding costs.

RFID tags on UAVs can store maintenance and calibration information, helping manufacturers track maintenance schedules and ensure compliance with regulations.

Check with aerospace and UAV industry associations in the USA and Canada, such as AUVSI (Association for Unmanned Vehicle Systems International) or industry-specific publications for case studies and reports.

Visit the websites of RFID solution providers that cater to the aerospace and manufacturing sectors. They may showcase case studies of their successful implementations.

Explore academic research papers and studies related to RFID applications in aerospace and manufacturing. Academic institutions and research organizations may have published relevant findings.

Government agencies involved in aerospace regulation and technology development may publish reports and studies that include RFID applications in UAV manufacturing.

Attend aerospace and UAV industry trade shows and conferences where experts and companies often share case studies and best practices.

Many applications of RFID by GAO can be found here.

Case Studies of IoT Applications

Below are some IoT application cases in unmanned aerial vehicle (UAV) manufacturing industry.

Check with UAV industry associations, such as AUVSI (Association for Unmanned Vehicle Systems International) or industry-specific publications. These organizations often publish articles, reports, and case studies related to UAV technology and applications.

Government agencies in the USA and Canada involved in aerospace and UAV regulation may publish reports and studies related to IoT applications in the UAV manufacturing sector.

Visit the websites of IoT solution providers that cater to the aerospace and manufacturing sectors. These providers may showcase case studies of successful IoT implementations in UAV manufacturing.

Explore academic research papers and studies related to IoT applications in aerospace and manufacturing. Universities and research institutions often conduct studies in collaboration with industry partners.

Attend aerospace and UAV industry trade shows and conferences. These events often feature presentations, panels, and sessions where experts and companies share case studies and best practices.

Explore IoT-specific publications and websites that cover industrial IoT applications. They may feature articles and case studies related to IoT in manufacturing, including UAV manufacturing.

Case Studies of Drone Applications

Below are some drone application cases in unmanned aerial vehicle (UAV) manufacturing industry.

Drones equipped with cameras and sensors can perform visual inspections of UAV components during manufacturing to detect defects and ensure quality.

Drones can assist in monitoring inventory levels of parts and materials within manufacturing facilities, helping optimize supply chain processes.

Drones can provide aerial views of production lines, assisting in monitoring and optimizing manufacturing processes.

Drones can be used for surveillance and security purposes to protect manufacturing facilities and assets.

Drones equipped with sensors can monitor environmental conditions in and around manufacturing facilities, ensuring compliance with regulations.

Drones can assist in transporting small components or materials within manufacturing facilities, improving efficiency.

Check with aerospace and UAV industry associations in the USA and Canada for case studies and reports related to drone applications in UAV manufacturing.

Visit the websites of drone solution providers that cater to the aerospace and manufacturing sectors. They may showcase case studies of successful drone implementations.

Explore academic research papers and studies related to drone applications in aerospace and manufacturing. Universities and research institutions may have published relevant findings.

Government agencies involved in aerospace and UAV regulation may publish reports and studies that include drone applications in UAV manufacturing.

Trade Shows and Conferences: Attend aerospace and UAV industry trade shows and conferences where experts and companies often share case studies and best practices related to drone technology.

GAO RFID Systems & Hardware for Unmanned Aerial Vehicle (UAV) Manufacturing Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including unmanned aerial vehicle (UAV) manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including unmanned aerial vehicle (UAV) manufacturing industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including unmanned aerial vehicle (UAV) manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including unmanned aerial vehicle (UAV) manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including unmanned aerial vehicle (UAV) manufacturing industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including unmanned aerial vehicle (UAV) manufacturing industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selectioon of high quality drones are offered:

The RFID systems by GAO are highly popular for clients in unmanned aerial vehicle (UAV) manufacturing industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include:

CNC Machines (Computer Numerical Control), 3D Printers, Laser Cutting Machines, Composite Material Layup Equipment, Inspection and Testing Equipment, Autoclaves, Soldering Stations, Electronic Component Placement Machines, Surface Mount Technology (SMT) Machines, Precision Measurement Tools, Wind Tunnels, Avionics Testing Equipment, Environmental Testing Chambers, Robotics and Automation Systems, Welding Machines, CNC Routers, Electrical Discharge Machining (EDM) Equipment, Computer-Aided Design (CAD) Workstations, Rapid Prototyping Machines, Material Handling Equipment, Vacuum Forming Machines, X-ray Inspection Equipment, Ultrasonic Testing Equipment, High-Precision Balancing Machines, Thermal Imaging Cameras, Vibrational Testing Equipment, Flight Simulation Systems, Paint and Coating Application Equipment, Electronic Test Benches, Ground Control Station (GCS) Equipment.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for unmanned aerial vehicle (UAV) manufacturing industry and for various industries in all metropolitans in the U.S. and Canada:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in the U.S. and Canada. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in unmanned aerial vehicle (UAV) manufacturing industry we have worked with to serve our joint customers:

- Deloitte

- PwC (PricewaterhouseCoopers)

- Accenture

- Capgemini

- IBM Global Business Services

- KPMG

- Booz Allen Hamilton

- Cognizant

- CGI

- Wipro

- Infosys

- L3Harris Technologies

- BAE Systems

- Leidos

- Raytheon Technologies

- Northrop Grumman Corporation

- General Atomics Aeronautical Systems, Inc. (GA-ASI)

- AeroVironment, Inc.

- Textron Systems

- Kratos Defense & Security Solutions

GAO Has Served Unmanned Aerial Vehicle (UAV) Manufacturing Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in unmanned aerial vehicle (UAV) manufacturing industry to achieve success in:

BVLOS (Beyond Visual Line of Sight), UAM (Urban Air Mobility), Counter-Drone Technology, Autonomy and AI, Swarming Technology, Electric and Hybrid Propulsion, 5G Connectivity, VTOL (Vertical Takeoff and Landing), Green UAVs, Long-Endurance UAVs, Payload Diversity, Regulatory Compliance, Counter-UAS (Counter Unmanned Aircraft Systems), Edge Computing, Sustainable Materials, 3D Printing, Drone-as-a-Service (DaaS), Environmental Monitoring, Precision Agriculture, Advanced Navigation.

GAO RFID Inc. has deployed RFID, BLE and IoT projects for many companies in unmanned aerial vehicle (UAV) manufacturing industry, including many in its various divisions such as:

- Aerospace Manufacturers: These companies design and manufacture UAVs, including fixed-wing and rotary-wing (drone) aircraft. They focus on airframe design, propulsion systems, and aerodynamics.

- Component Manufacturers: Specialized manufacturers produce UAV components, such as avionics, sensors, cameras, engines, and propellers.

- Payload and Sensor Manufacturers: Companies in this division develop and manufacture various payloads and sensors for UAVs, including cameras, LiDAR systems, multispectral sensors, and thermal imaging devices.

- UAV Software Developers: These companies create software solutions for UAVs, including flight control software, navigation systems, mission planning, and data analysis tools.

- Remote Sensing and Data Analysis: Firms specializing in remote sensing and data analysis use UAV-collected data for applications like agriculture, environmental monitoring, and geospatial analysis.

- Maintenance and Repair Services: Companies in this division provide maintenance, repair, and overhaul (MRO) services for UAVs, ensuring they remain operational and safe.

- Training and Education: Organizations offer training programs and education for UAV operators, pilots, and maintenance technicians.

- Consulting and Integration Services: These firms provide consulting and integration services to help organizations implement UAV technology into their operations effectively.

- Regulatory Compliance and Legal Services: Experts in UAV regulations and legal compliance assist companies in navigating the complex legal and regulatory landscape surrounding UAV operations.

- Drone Service Providers (DSPs): These companies offer UAV services, including aerial photography, mapping, inspection, and surveillance, often using their fleet of UAVs.

- Research and Development (R&D): Organizations engaged in UAV R&D work on cutting-edge technologies and innovations, pushing the boundaries of UAV capabilities.

- Defense and Military UAVs: Specialized manufacturers and service providers cater to the defense and military sector, developing UAVs for surveillance, reconnaissance, and combat applications.

- Consumer and Commercial UAVs: Companies focus on manufacturing UAVs for consumer and commercial use, including recreational drones, aerial photography, and delivery services.

- Environmental and Agricultural UAVs: Specialized UAVs designed for environmental monitoring, agriculture, and forestry applications, often equipped with sensors for data collection.

- Aerospace and Defense Contractors: Large aerospace and defense corporations that produce UAVs alongside other aerospace and defense technologies.

- Startups and Innovators: Emerging companies and startups driving innovation in UAV technology, often focusing on niche applications or unique designs.

GAO’s technologies enable its customers in unmanned aerial vehicle (UAV) manufacturing industry to effectively track their workforces such as:

UAV Engineer, Systems Integration Specialist, Manufacturing Technician, Quality Control Inspector, Aerospace Designer, Avionics Technician, Flight Test Engineer, Production Manager, Research and Development Scientist, Supply Chain Manager, UAV Operator, Software Developer, Test Pilot, Materials Engineer, Technical Support Specialist, Procurement Analyst, CAD Designer, Electrical Engineer, Manufacturing Supervisor, Safety Officer, Project Manager, Data Analyst, Logistics Coordinator, UAV Technician, Firmware Engineer, Regulatory Compliance Specialist, Flight Operations Manager, Maintenance Technician, Human Resources Manager, Marketing Manager and effectively track operational assets such as:

UAV Testing Equipment, CNC Machines, 3D Printers, Avionics Testing Tools, Payload Integration Equipment, Composite Material Fabrication Machinery, Computer-Aided Design (CAD) Software, Quality Control Instruments, UAV Assembly Line Equipment, Environmental Test Chambers, Flight Simulation Software, Inspection Drones, UAV Ground Control Stations, Welding Machines, Material Testing Machines, UAV Propulsion Testing Facilities, Electrical Testing Equipment, Robotic Automation Systems, CNC Routers, Fiber Placement Machines, Ultrasonic Testing Devices, Non-destructive Testing (NDT) Equipment, Radio Frequency (RF) Testing Instruments, Laser Cutting Machines, Thermal Imaging Cameras, Radio Communication Equipment, Battery Testing Equipment, Hydraulic Presses, Wind Tunnels, Surface Finishing Tools.

Here are some of the leading companies in unmanned aerial vehicle (UAV) manufacturing industry GAO has served:

- General Atomics Aeronautical Systems, Inc.

- Northrop Grumman Corporation

- Lockheed Martin

- Textron Inc. (parent company of Bell)

- Kratos Defense & Security Solutions

- Raytheon Technologies

- Elbit Systems of America

- Precision Hawk

- Aurora Flight Sciences

- Griffon Aerospace

- L3Harris Technologies

- MartinUAV

- Skydio

- Silent Falcon UAS Technologies

- Valqari

- Parallax Advanced Research

- Impossible Aerospace

- XAG America

- Aeronyde

- Quantum Systems

- Latitude Engineering

- Swift Engineering

- SkyX Systems Corporation

- Draganfly Inc.

- ING Robotic Aviation

- Maru Technologies Inc.

- Percept Systems

- NOVAerial Robotics Inc.

You Are Invited to Contact Us!

If you interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com