The water and wastewater treatment construction industry is responsible for designing, constructing, installing, and maintaining facilities that treat and manage water and wastewater. This includes treatment plants for drinking water, industrial use, and discharge, as well as infrastructure like pipes and storage tanks. Its primary objective is to ensure safe and high-quality water supply, protect the environment, and promote public health.

GAO RFID Inc., one of the global top 10 RFID leaders, is based in the cities of New York and Toronto and it has deployed many RFID, BLE and IoT projects in the water and wastewater treatment construction.

GAO RFID Systems & Hardware for the Water and Wastewater Treatment Construction

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the water and wastewater treatment construction.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for all kinds of industries, including the water and wastewater treatment construction.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the water and wastewater treatment construction :

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the water and wastewater treatment construction:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the water and wastewater treatment construction:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the water and wastewater treatment construction:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the water and wastewater treatment construction:

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

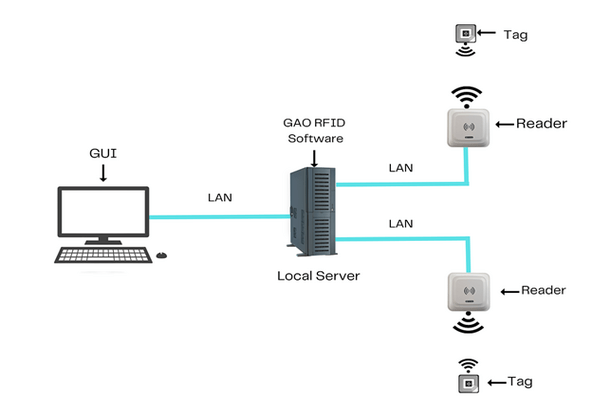

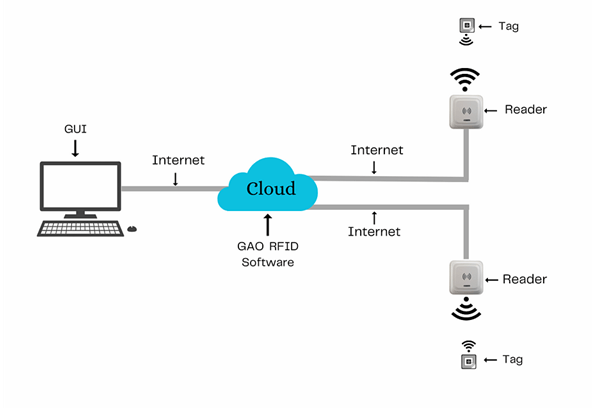

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

GAO offers free samples of its RFID tags, labels, badges, and wristbands.

GAO offers a free trial for all of its software available.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Water and Wastewater Treatment Construction

BLE gateways and beacons, drones with RFID, and IoT with RFID have various applications and benefits in the water and wastewater treatment construction industry:

BLE gateways and beacons can be used to improve asset tracking and management in the water and wastewater treatment construction industry. By attaching beacons topumps, valves, pipes and fittings, tanks and basins, blowers and compressors; materials, and personnel, their location and movement can be monitored in real-time. BLE gateways can collect this data and send it to a central database, enabling managers to optimize workflows and ensure that all necessary assets are in the right place at the right time. BLE beacons can be placed on key assets such as pumps, valves, and pipes, and can transmit data to BLE gateways, which then relay the information to a central control system. This allows for quick identification of any issues or anomalies, which can be addressed before they become major problems. Additionally, BLE gateways and beacons can enhance safety by providing location-based alerts to workers and contractors, alerting them of any potential hazards in the area.

Drones equipped with RFID technology can be used to inspect and monitor water and wastewater treatment facilities. RFID tags can be placed on various assets and components, allowing drones to quickly and easily locate and identify them during inspections. This can help reduce inspection time and improve accuracy, as well as enable remote monitoring of hard-to-reach areas of the facility. These drones can be used to conduct inspections of hard-to-reach areas, track the location of critical assets, and monitor inventory movements on the construction site. By enabling real-time monitoring and data collection of critical infrastructure, drones equipped with RFID technology can help to enhance operational efficiency, improve safety, and reduce the risk of lost or misplaced items in water and wastewater treatment construction projects.

IoT with RFID technology can be used to monitor water quality and ensure that the treatment process is working effectively. RFID sensors can be used to monitor parameters such as pH, temperature, and turbidity, and send this data to a central database. This data can be analyzed in real-time to identify any issues and optimize the treatment process. Additionally, RFID tags can be used to track the movement of wastewater through the treatment process, providing valuable data for process optimization and quality control. By combining these technologies, it is possible to create a fully integrated and automated system for monitoring and managing critical infrastructure and assets. IoT devices can be used to collect data from sensors installed throughout the construction site, providing real-time information on the performance and condition of equipment, as well as the quality of water and wastewater. RFID technology can be used to track the location and movement of assets, providing greater visibility and control over inventory. This creates a more efficient, reliable, and secured system for managing water and wastewater treatment construction projects.

GAO Helps Customers Comply with Standards, Mandates & Regulations

GAO RFID Inc. has helped many companies in the water and wastewater treatment construction industry to deploy RFID systems and to ensure such deployments complying with the applicable industry standards, mandates and regulations:

ASTM F2971-19: Provides guidance on the use of RFID technology for identifying and tracking water and wastewater pipes, fittings, and valves.

EPA 832-R-17-003: Provides information on the use of RFID technology for wastewater treatment plant process control and monitoring.

Safe Drinking Water Act (SDWA): It sets national standards for drinking water, regulates underground injection wells, and funds infrastructure improvements, with the EPA in charge of implementation.

Occupational Safety and Health Administration (OSHA) regulations: It mandates safety and health standards for workers, such as confined spaces and hazardous materials handling rules, applicable to wastewater treatment facilities.

National Environmental Policy Act (NEPA): It requires environmental impact consideration for federally funded wastewater facilities.

Canadian Environmental Protection Act (CEPA): CEPA regulates pollutants and waste, including hazardous substances management and effluent discharge regulations, encompassing water and wastewater treatment.

Fisheries Act: The federal law that safeguards fish and their habitats, including those affected by wastewater facilities, by regulating the release of deleterious substances and requiring permits for works impacting fish habitats.

Wastewater Systems Effluent Regulations (WSER): It limits effluent discharge from wastewater treatment plants in water used for recreation or frequented by fish, effective since 2015.

GAO’s Software Provides API

GAO’s popular RFID software such as personnel tracking, asset tracking, access control, parking system control offers a free trial and offers an API to each of the common software in the water and wastewater treatment construction industry:

Personnel management:

Recruitment and selection of staff: Finding and hiring the right people for the job.

Employee training and development: Ensuring employees have the skills they need to do their jobs effectively.

Performance management: Setting goals, providing feedback, and evaluating employee performance.

Safety and health management: Creating a safe work environment and ensuring compliance with regulations.

Employee engagement and communication: Fostering a positive work culture and open lines of communication with employees.

Succession planning: Identifying and developing employees for future leadership roles.

Equipment management:

Equipment selection and procurement: Choosing the right equipment and purchasing it.

Preventive maintenance planning: Scheduling regular maintenance to prevent breakdowns.

Equipment repair and replacement: Fixing or replacing broken equipment.

Equipment calibration and testing: Ensuring equipment is accurate and meets standards.

Inventory control: Managing equipment inventory to avoid shortages or excesses.

Asset tracking and management: Tracking equipment location, status, and maintenance history.

Supply chain management:

Vendor selection and management: Choosing and managing suppliers of goods and services.

Procurement planning and execution: Planning and executing purchases of materials and equipment.

Contract management: Managing contracts with vendors and subcontractors.

Logistics and transportation management: Managing the movement of materials and equipment to and from the site.

Inventory management and optimization: Managing inventory levels to minimize waste and maximize efficiency.

Demand forecasting and planning: Predicting future demand for materials and equipment.

Other applications:

Project management: Planning, executing, and monitoring projects to achieve goals within scope, time, and budget constraints.

Risk management: Identifying, assessing, and managing risks to the project or organization.

Quality control and assurance: Ensuring that products and services meet quality standards.

Environmental compliance management: Ensuring compliance with environmental regulations and minimizing environmental impact.

Cost accounting and financial management: Managing project and organizational finances.

Regulatory compliance and permitting: Ensuring compliance with legal and regulatory requirements.

Case Studies of RFID Applications in the Water and Wastewater Treatment Construction

Here’s are case studies of RFID application in the water and wastewater treatment construction:

San Diego in California carried out a RFID-based resource global positioning framework. Because the system uses RFID tags to track equipment and inventory, the plant can better manage its resources at a lower cost. RFID peruses can be tracked down all around the plant, as well as RFID labels that are joined to hardware and stock things. When the item is moved, the information from the RFID tag is sent to a central database and read by the reader that is closest to the object. This enables the plant to guarantee the availability of inventory and equipment at any time by monitoring their location in real time. The RFID system has reduced the likelihood of equipment being misplaced or lost, saving the plant both time and money on inventory management. The system has also enabled the plant to identify underutilized or no longer required equipment, allowing it to save money and maximize resources.

Another case study is Aqua America, a US water and wastewater treatment company, implemented an RFID-based system to track water meters and other equipment. RFID readers can be found all over the plant, as well as RFID tags that are attached to each water meter in the system. The RFID tag is automatically scanned when a meter is read, and the information is sent to a central database. The plant is able to monitor the consumption of water in real time and spot any potential leaks or other issues. Additionally, the system includes alerts that enable the plant to quickly respond to potential issues when water consumption exceeds predetermined thresholds. The plant has been able to reduce water waste and improve water management thanks to the RFID system. It has also been able to spot potential issues with the equipment before they become major issues. The plant has also been able to streamline its operations and increase overall efficiency thanks to the system.

GAO Has Served the Water and Wastewater Construction Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in the water and wastewater treatment construction industry, including its various divisions as

Storm water management: This sub-industry involves designing, constructing, and maintaining systems to mitigate storm water runoff’s impact on the environment, using new technologies and best practices.

Water treatment: This sub-industry designs, constructs, operates facilities using new technologies for producing safe drinking water for homes, businesses, and municipalities, including constructing new treatment plants and maintaining existing ones.

Wastewater treatment: This sub-industry involves designs, constructs, and operates facilities to treat raw water, develop new technologies, and maintain existing plants to produce safe drinking water for homes, businesses, and municipalities.

Desalination: This sub-industry produces fresh water from salt water sources using reverse osmosis and distillation technologies to remove impurities from oceans or brackish groundwater.

Water reuse: This sub-industry treats wastewater for non-potable purposes, with new technologies, construction and maintenance of treatment plants, for irrigation, industrial processes or groundwater recharge.

Some of the leading companies in the Water and Wastewater Treatment Construction industry in the US:

Some of the leading companies in the Water and Wastewater Treatment Construction industry in the Canada: