The yarn and thread manufacturing industry involves the production of various types of yarns and threads that are used in a wide range of applications, such as textiles, apparel, home furnishings, industrial products, and medical supplies. Yarns are typically made from fibers, such as cotton, wool, silk, or synthetic materials, that are spun together to form a continuous strand. Threads, on the other hand, are usually made from multiple yarns twisted together to increase strength and durability.

GAO RFID Inc., a global top 10 RFID leader based in the cities of New York and Toronto, has served many companies in the yarn and thread manufacturing industry.

GAO RFID Systems & Hardware for Yarn and Thread Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the yarn and thread manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for all kinds of industries, including the yarn and thread manufacturing industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the yarn and thread manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the yarn and thread manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the yarn and thread manufacturing industry:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the yarn and thread manufacturing industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the yarn and thread manufacturing industry:

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

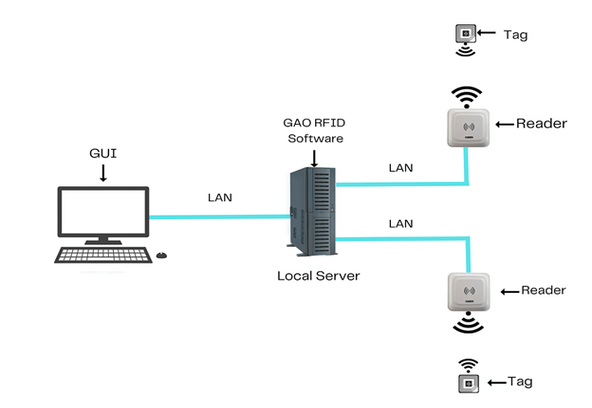

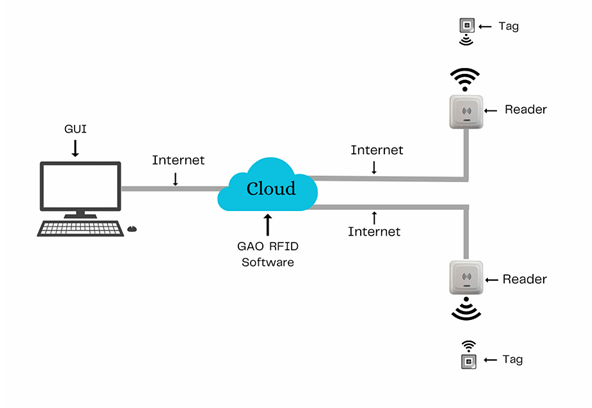

There are two versions of GAO’s software, one is running on local server, and another running in the cloud.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Yarn and Thread Manufacturing

RFID, BLE, IoT and drone technologies from GAO RFID Inc. offer many benefits for the yarn and thread manufacturing industry:

Application & benefits of applying RFID to Yarn and Thread Manufacturing:

- Inventory management: GAO’s RFID product can be used to automate the inventory management process by enabling accurate, real-time tracking of raw materials, work-in-progress, and finished goods.

- Quality control: Our RFID tags can be used to identify and track individual spools of yarn or thread throughout the manufacturing process, allowing for improved quality control and faster defect detection.

- Counterfeiting prevention: GAO’s RFID solution is used to prevent the counterfeiting of yarn and thread by providing a unique identifier for each product that can be authenticated throughout the supply chain.

Applications & benefits of applying BLE technology to Yarn and Thread Manufacturing

- Real-time Monitoring: GAO’s BLE technology is used to monitor yarn and thread manufacturing processes in real-time. By attaching BLE-enabled sensors to machines, it is possible to track parameters such as temperature, humidity, and machine status.

- Process Automation: Our BLE solution can be used to automate the yarn and thread manufacturing process. By using BLE-enabled sensors and actuators, it is possible to create a closed-loop system that can automatically adjust parameters such as tension and speed to optimize the manufacturing process.

- Energy Efficiency: GAO’s BLE product is used to monitor energy consumption during the yarn and thread manufacturing process. By tracking energy usage in real-time, it is possible to identify areas of inefficiency and optimize energy consumption to reduce costs.

Applications & benefits of applying combination of RFID and IoT to Yarn and Thread Manufacturing

- Asset tracking: Our RFID tags in combination with IoT can be used to track the location of machinery and other assets in the manufacturing process.

- Predictive maintenance: GAO’s RFID products is combined with IoT sensors to monitor the performance of machinery and identify potential maintenance issues before they become serious.

- Sustainability: The use of GAO RFID products and IoT can help manufacturers to track the use of resources such as energy and water and identify opportunities to reduce waste and improve sustainability.

Applications & benefits of applying combination of RFID and drones to Yarn and Thread Manufacturing

- Monitoring production: Combining GAO’s RFID technology with drones, manufacturers can collect data on production rates, equipment utilization, and other key metrics to optimize their operations.

- Supply chain management: By using GAO’s RFID products in combination with drones to transport spools of yarn and thread between manufacturing facilities, warehouses, and distribution centers; manufacturers can streamline their supply chain and reduce transportation costs.

- Safety and security: Drones equipped with our RFID solution can be used to monitor and secure manufacturing facilities, warehouses, and distribution centers. By scanning RFID tags on workers’ badges, drones can ensure that only authorized personnel are on-site, improving safety and security.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Yarn and Thread Manufacturing

GAO RFID Inc. has helped many companies in yarn and thread manufacturing industry to deploy RFID systems and to ensure such deployments comply with the applicable industry standards, mandates, and government regulations:

- OSHA Cotton Dust Standard: This standard applies specifically to facilities that produce or process cotton products and sets limits on the amount of cotton dust that workers can be exposed to.

- EPA Clean Air Act: This act sets limits on the amount of air pollution that industrial facilities can produce, including emissions from yarn and thread manufacturing processes.

- CPSC Flammability Standards: These standards apply to textiles and other materials used in clothing and other consumer products and set limits on the flammability of these materials.

- CEPA Priority Substances List: This list identifies substances that are considered to be potentially hazardous to human health or the environment and sets limits on their use and disposal.

- Health Canada’s Hazardous Products Act: This act sets standards for the labeling and packaging of hazardous products, including chemicals used in yarn and thread manufacturing.

- Ministry of Environment and Climate Change’s Air Pollution Regulations: These regulations set limits on the amount of air pollution that industrial facilities can produce, including emissions from yarn and thread manufacturing processes.

- Canadian General Standards Board’s Textile Standards: These standards cover a range of issues related to textile manufacturing, such as fiber content, colorfastness, and flammability.

GAO’s Software Provides API

GAO’s popular RFID software such as personnel tracking, asset tracking. access control, parking system control, work-in-progress offers a free trial and an API to each of the common software in the yarn and thread manufacturing industry:

Personnel Management

- Human Resource Management System: This is used in managing the recruitment process, tracking employee attendance, handling payroll and providing training and development activities.

- Time and Attendance Management System: This solution helps businesses track and manage employee attendance, work hours, and other related data.

- Performance Management System: This is a set of processes and tools designed to measure, evaluate and improve employee performance within an organization.

Equipment Management

- Equipment Maintenance Management: This is used to organize, plan, schedule, and execute maintenance activities on equipment and machinery to ensure they function efficiently.

- Asset Tracking: This is used to track the location of equipment, monitor usage and prevent theft.

- Equipment Rental Management: This software helps yarn and thread manufacturing companies schedule maintenance, track repair history, and generate reports on equipment maintenance.

Supply Chain Management

- Procurement: This helps in managing the procurement process by tracking supplier performance, identifying cost-saving opportunities, and automating purchase orders.

- Logistics: This system helps in optimizing the logistics operations by tracking delivery schedules, managing inventory levels, and coordinating transportation.

- Inventory Management: This solution can help in managing the inventory levels, track usage rates, and forecast demand to ensure that they have the right amount of inventory at the right time.

- Supplier Management: This system can help in managing the supplier relationships by tracking performance metrics, facilitating communication, and ensuring compliance with contractual agreements.

- Risk Management: This system mitigates the risks by identifying potential disruptions, creating contingency plans, and implementing risk management strategies.

Other Applications

- Access Control System: This software is used to manage access to secure areas of job sites, including controlling access to manufacturing equipment and vehicles.

- Waste Management System: This software is used to track the movement of waste and recycling materials on job sites, including providing data on waste volume and disposal methods.

Case Studies of RFID Applications

A case study of RFID application in yarn and thread manufacturing in the US:

Coats North America implemented an RFID solution to track the movement of raw materials, finished goods, and work-in-progress (WIP) throughout their manufacturing process. The RFID solution helped Coats North America to improve their inventory management, reduce waste, and increase productivity. The company was able to automate their inventory control process, eliminate manual data entry, and reduce errors associated with manual tracking methods. The RFID solution consisted of RFID tags attached to the raw materials, finished goods, and WIP, as well as RFID readers placed at various locations throughout the manufacturing process. The RFID tags were read by the RFID readers as the materials and goods moved through the process, providing real-time information on their location and status. The RFID solution also provided Coats North America with better visibility into their supply chain, enabling them to identify and address bottlenecks and inefficiencies in their manufacturing process. This helped the company to reduce lead times, improve customer service, and increase profitability.

Here is another case study of RFID application in yarn and thread manufacturing in the US:

A large yarn and thread manufacturing company in the US implemented an RFID-based inventory tracking system in their manufacturing process. The company used RFID tags that were attached to each fiber, which were then tracked using RFID readers throughout the manufacturing process. The RFID tags were able to track the location of each fiber in real-time, which helped in improving inventory management. The company was able to ensure that the right amount of inventory was always available and was able to reduce wastage. The company was also able to improve the efficiency of their manufacturing process. With RFID technology, the manual labor required to manage inventory was significantly reduced, which helped in improving the overall efficiency of the manufacturing process.

GAO Has Served Yarn and Thread Manufacturing Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in the yarn and thread manufacturing industry, including its various divisions such as

- Natural Fibers: This sub-industry includes yarn and thread made from natural fibers like cotton, wool, silk, and hemp.

- Synthetic Fibers: This sector includes yarn and thread made from synthetic fibers like polyester, nylon, and acrylic.

- Specialty Fibers: This division includes yarn and thread made from specialty fibers like carbon, glass, and aramid.

- Handicraft and Hobby Yarns: This sector includes yarn and thread specifically designed for use in handicrafts and hobbies like knitting, crocheting, and embroidery.

- Industrial Threads: This division includes threads designed for use in industrial applications like sewing machines, embroidery machines, and weaving machines.

- Sewing Threads: This sector includes threads designed for use in sewing garments, upholstery, and other textile products.

- Embroidery Threads: This sub-industry includes threads designed for use in machine and hand embroidery.

- Quilting Threads: This sector includes threads designed for use in quilting, which is a type of handicraft that involves stitching multiple layers of fabric together to create a padded material.

- Upholstery Threads: This division includes threads designed for use in upholstery, which involves covering furniture with fabric or leather.

- Crochet Threads: This sub-industry includes threads specifically designed for use in crochet, a type of handicraft that involves creating textiles by interlocking loops of yarn or thread with a crochet hook.

List of the leading companies in yarn and thread manufacturing in the U.S.

List of the leading companies in yarn and thread manufacturing in Canada