The petroleum and coal products manufacturing industry encompasses the processing of crude oil, natural gas liquids, and coal into various products such as gasoline, diesel fuel, lubricants, plastics, and chemicals. This industry includes refining operations, as well as the manufacturing of coke and other coal products. The industry is a major contributor to global energy production and is heavily influenced by fluctuations in crude oil prices. GAO RFID Inc., one of the global top 10 RFID leaders, is based in the cities of New York and Toronto and it has deployed many RFID, BLE and IoT projects in the petroleum and coal products manufacturing industry.

GAO RFID Systems & Hardware for the Petroleum and Coal Products Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the petroleum and coal products manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humidity, vibration, and panic button:

- IP67 Rated BLE 2.45GHz Active RFID Wristband Tag w

- BLE 2.45GHz Ultra Rugged Active RFID Pallet Tag

- BLE 2.45GHz Active RFID Asset Tag/Beacon

GAO’s BLE technology is suitable for all kinds of industries, including the petroleum and coal products manufacturing industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the petroleum and coal products manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the petroleum and coal products manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the petroleum and coal products manufacturing industry:

- 134.2KHz ISO11784/5 FDX RFID Plug and Play Portable Reader

- 134.2 kHz LF Long Range Fixed RFID Reader

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the petroleum and coal products manufacturing industry

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the petroleum and coal products manufacturing industry:

People or workers tracking system:

Physical asset or operational equipment tracking system:

- GAO RFID Construction and Industrial Machinery Rental Asset Management System

- Gen2 UHF 902-928 MHz Passive RFID Readers

- Gen 2 UHF 865-868 MHz Passive RFID Readers

Personnel or people access control system:

Parking or vehicle control system:

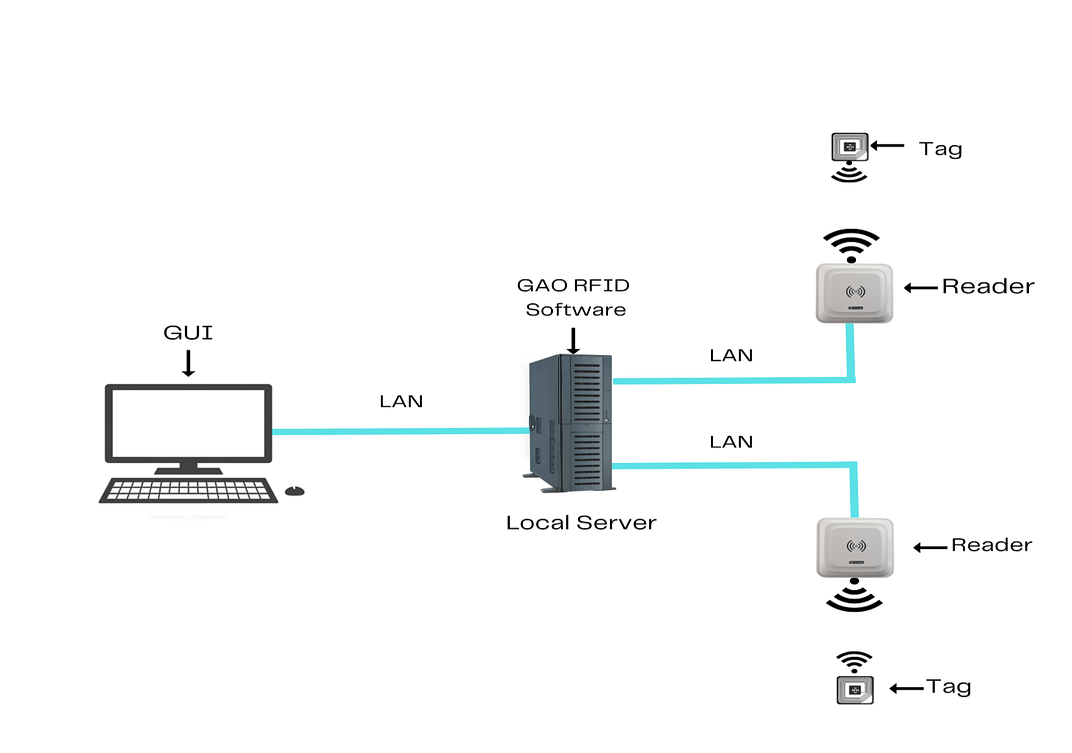

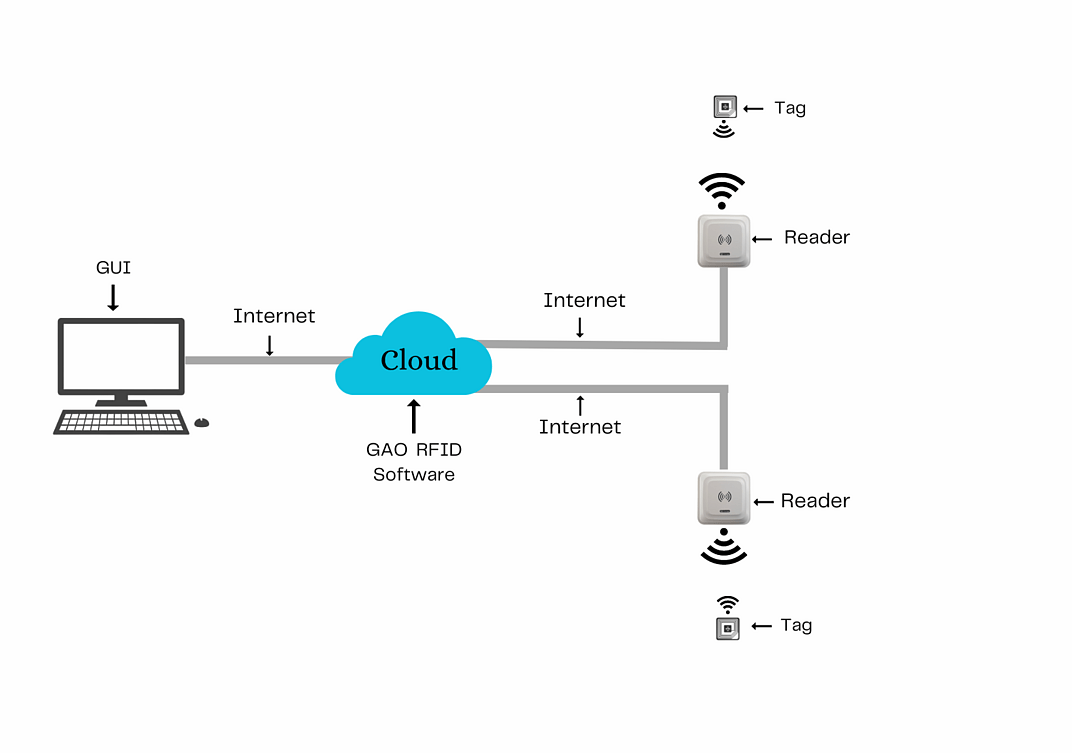

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

GAO’s software runs on a local server.

GAO’s software runs on a local server.

GAO’s software runs in the cloud.

GAO’s software runs in the cloud.

Applications & Benefits of GAO’s RFID, GAO’S BLE, IoT & Drones for the Petroleum and Coal Products Manufacturing

Applications & Benefits of GAO’s RFID, GAO’S BLE, IoT& Drone for the Petroleum and Coal Products Manufacturing

- Improved inventory management: GAO’S RFID can be used to track and monitor inventory in real-time. This can help companies identify when inventory is running low and when to reorder, reducing the risk of stockouts and minimizing inventory carrying costs.

- Enhanced safety: Our RFID can help ensure that equipment and personnel are in the right place at the right time. For example, our RFID tags can be used to track the location of workers and equipment such as crude oil, natural gas in hazardous areas, reducing the risk of accidents.

- Better supply chain management: By using our RFID technologies, track shipments of raw materials and finished products such as coal and asphalt, enabling companies to better manage their supply chain and improve delivery times.

- Reduced theft and loss: Our RFID solutions can be used to track and monitor high-value assets, reducing the risk of theft and loss. This can lead to significant cost savings for companies.

Applications & Benefits of Applying BLE technology to the Petroleum and Coal Products Manufacturing:

- Asset Tracking: GAO’S BLE technology can be used to track the movement of assets such as equipment, vehicles, and containers in real-time. This helps in reducing operational costs, improving safety and security, and optimizing the utilization of resources.

- Environmental Monitoring: Our BLE sensors can be used to monitor the environment for factors such as temperature, humidity, and air quality. This is particularly useful in industries such as petroleum and coal products manufacturing, where environmental conditions need to be monitored to ensure safety and compliance with regulations.

- Predictive Maintenance: By using our BLE technologies, we can monitor the performance of machinery and equipment in real-time. This allows for early detection of potential problems, allowing for preventive maintenance to be carried out before a breakdown occurs. This reduces downtime, maintenance costs, and improves the overall efficiency of operations.

- Safety Monitoring: Our BLE solutions can be used to monitor the safety of workers in hazardous environments such as refineries and chemical plants. For example, wearable devices equipped with BLE sensors can monitor the health of workers and alert supervisors in case of an emergency.

Applications & Benefits of Applying Combination of RFID and Drones to the Petroleum and Coal Products Manufacturing

- Inventory Management: GAO’S RFID technology can be used to track inventory levels of raw materials and chemicals such as asphalt, catalysts, and additives, and finished products such as crude oil, coal, sulfur, nitrogen, gasoline, diesel fuel in real-time. Drones can be used to collect this data quickly and efficiently, enabling better inventory management and supply chain optimization.

- Inspection and Maintenance: Drones equipped with our RFID readers can be used to inspect and maintain oil rigs, pipelines, and others in remote and hard-to-reach locations. By using our RFID technology to identify and track specific components, maintenance teams can quickly identify and repair any issues before they become more serious problems.

- Environmental Monitoring: Drones can be used to collect data on environmental factors such as air and water quality, temperature, and humidity. Our RFID tags can be used to identify specific locations allowing for more targeted and efficient monitoring.

Applications & Benefits of Applying Combination of RFID and IoT to Petroleum and Coal Products Manufacturing

- Enhanced safety and security: GAO’s RFID and IoT technologies can be used to monitor and control access to sensitive areas, track hazardous materials such as crude oil, gasoline, diesel fuel, natural gas, coal, and various chemicals, and detect potential safety hazards. This can help prevent accidents and improve overall safety and security in the workplace.

- Improved asset tracking and management: Our RFID tags can be used to track and monitor assets, such as equipment and inventory, in real-time, providing better visibility and control over operations. IoT sensors can also be used to collect data on asset performance, enabling predictive maintenance and reducing downtime.

- Increased operational efficiency: By using our RFID and IoT technologies, automate processes such as inventory management and maintenance scheduling, reducing manual labor and improving efficiency. This can help reduce costs and increase productivity.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Petroleum and Coal Products Manufacturing

GAO’s RFID Inc. has helped many companies in the petroleum and coal products manufacturing industry to deploy RFID systems and to ensure such deployments complying with the applicable industry standards, mandates and government regulations:

- Petroleum Equipment Institute (PEI) RP1200: This standard provides guidelines for the design and installation of fueling systems, including the use of RFID technology for inventory management and security.

- Transportation Security Administration (TSA) CFR 49: This regulation requires that hazardous materials be properly labeled and tracked during transportation. RFID technology can be used to help ensure compliance with this regulation.

- API RP 1626: This is the recommended practice for the use of RFID in the petroleum and petrochemical industries. It provides guidance on the use of RFID technology for tracking and managing materials, equipment, and personnel.

- S. Customs and Border Protection (CBP) – Automated Commercial Environment (ACE): The ACE system requires importers and exporters to provide detailed information about their shipments. RFID technology can be used to track the movement of goods and ensure compliance with CBP regulations.

- Canadian Standards Association (CSA) Z662: This standard governs the design, construction, and operation of oil and gas pipelines in Canada. RFID technology can be used to track and manage pipeline assets and ensure compliance with the CSA’s regulations.

- S. Department of Transportation (DOT) CFR 49: This regulation requires that hazardous materials be properly labeled and tracked during transportation. RFID technology can be used to help ensure compliance with this regulation.

Canadian Standards Association (CSA)

Canadian Standards Association (CSA)

U.S. Customs and Border Protection (CBP)

U.S. Customs and Border Protection (CBP)

U.S. Department of Transportation (DOT)

U.S. Department of Transportation (DOT)

American Petroleum Institute (API)

American Petroleum Institute (API)

Transportation Security Administration (TSA)

Transportation Security Administration (TSA)

Petroleum Equipment Institute (PEI)

Petroleum Equipment Institute (PEI)

GAO’s Software Provides API

GAO’s popular RFID software such as personnel tracking, asset tracking, access control, parking system control(work-in-progress) offers a free trial and offers an API to each of the common software in the petroleum and coal products manufacturing industry:

Personnel Management:

- Recruitment and Retention: Attracting and retaining qualified and skilled personnel is critical for the petroleum and coal products manufacturing industry. This includes identifying and recruiting talent with the right skills, experience, and qualifications to work in challenging environments.

- Training and Development: Employees need to be continually trained and developed to keep up with changing technologies, safety regulations, and environmental standards. This includes providing training on operating procedures, safety protocols, and equipment maintenance.

- Performance Management: Performance management helps ensure that employees are meeting or exceeding job expectations. This includes setting clear performance expectations, providing regular feedback, and measuring performance against established goals and objectives.

- Succession Planning: Succession planning is the process of identifying and developing employees to take on key leadership roles within the organization. This ensures that the organization has the necessary leadership talent to guide the business into the future.

Equipment Management:

- Maintenance and Repair: Proper maintenance and repair of equipment such as sensors, pumps, valves, and meters are critical for the safety and efficiency of the operation. This includes performing regular inspections, conducting preventative maintenance, and repairing equipment as needed.

- Replacement Planning: Replacement planning helps ensure that equipment such as refining, pipeline and lab equipment is replaced before it becomes outdated or unsafe. This includes developing a replacement schedule, identifying replacement equipment, and planning for the financial resources needed to make replacements.

- Inventory Management: Proper inventory management ensures that equipment such as bar code scanners, crude oil, coal and chemicals such as solvents, catalysts, are readily available when needed. This includes tracking equipment inventory, identifying potential supply chain issues, and planning for the acquisition of new equipment.

Supply Chain Management:

- Procurement: Procurement involves identifying and acquiring the necessary raw materials such as asphalt, coal, chemicals and supplies to support the manufacturing process. This includes identifying suppliers, negotiating contracts, and managing supplier relationships.

- Logistics: Logistics involves managing the transportation and distribution of products and materials such as lubricants, natural gas, crude oil and containers, and bottles as packaging materials. This includes managing transportation routes, coordinating shipments, and optimizing delivery schedules.

- Inventory Management: Proper inventory management ensures that the right materials such as gasoline, diesel, trucks, tankers, and pipelines are available when needed. This includes tracking inventory levels, identifying potential supply chain issues, and planning for the acquisition of new materials.

Other Applications:

- Safety Management: The petroleum and coal products manufacturing industry can use safety management to ensure that their employees are working in a safe and secure environment. This involves identifying and addressing potential hazards, implementing safety procedures, and providing training to employees.

- Environmental Management: This involves managing the environmental impact of the petroleum and coal products manufacturing industry. This can include identifying and addressing potential environmental hazards, implementing environmental management procedures, and complying with environmental regulations.

Case Studies of RFID Applications

A case study of RFID application in the petroleum and coal products manufacturing industry in the U.S:

One of the companies in the petroleum and coal products manufacturing industry in the U.S. that has implemented RFID technology is Chevron Corporation. Chevron uses RFID to track the movement of their employees and contractors within their refineries and plants. The RFID tags are embedded in the identification badges of the employees, which allows Chevron to monitor their location and movement. This application of RFID enhances safety and security by ensuring that only authorized personnel are in restricted areas.

Another case study of RFID application in the Petroleum and coal products manufacturing industry in the U.S:

Valero Energy Corporation, which is one of the largest oil refining companies in the U.S. Valero uses RFID to track their assets, such as drums, tanks, and containers, throughout their refineries and distribution centers. The RFID tags are attached to the assets and provide real-time data on their location and status. This data is then used to optimize the supply chain by reducing the time and costs associated with locating and tracking assets.

GAO Has Served the Petroleum and Coal Products Manufacturing Extensively

GAO RFID Inc., one of the global top 10 RFID leaders, is based in the cities of New York and Toronto and it has deployed RFID, BLE and IoT projects for many leading companies in the petroleum and coal products manufacturing industry, including its various divisions such as

- Refineries: Refineries are the primary sub-industry within the Petroleum and coal products manufacturing industry. They process crude oil into a variety of products including gasoline, diesel fuel, heating oil, jet fuel, and other petroleum-based products.

- Petrochemicals: Petrochemical plants convert raw materials such as natural gas liquids and naphtha into chemicals used in the production of plastics, synthetic rubber, fibers, and other materials.

- Lubricants: Lubricant manufacturing involves the production of oils and greases used in machinery and engines.

- Asphalt: Asphalt manufacturing involves the production of asphalt and related products used in road construction, roofing, and other applications.

- Coke: Coke manufacturing involves the production of a carbon-rich fuel used primarily in steel production.

- Carbon black: Carbon black manufacturing involves the production of a material used in the production of tires, rubber products, and other applications.

- Other specialty products: This category includes various other specialty products such as

Some of the leading companies in the petroleum and coal products manufacturing in the U.S:

Exxon Mobil Corporation

Exxon Mobil Corporation

Chevron Corporation

Chevron Corporation

Phillips 66

Phillips 66

ConocoPhillips

ConocoPhillips

Marathon Petroleum Corporation

Marathon Petroleum Corporation

Valero Energy Corporation

Valero Energy Corporation

British Petroleum America Incorporated

British Petroleum America Incorporated

Koch Industries Incorporated

Koch Industries Incorporated

Holly Frontier Corporation

Holly Frontier Corporation

PBF Energy Incorporated

PBF Energy Incorporated

Alon USA Energy Incorporated

Alon USA Energy Incorporated

Delek US Holdings Incorporated

Delek US Holdings Incorporated

Western Refining Incorporated

Western Refining Incorporated

Sinclair Oil Corporation

Sinclair Oil Corporation

World Fuel Services Corporation

World Fuel Services Corporation

Andeavor Limited Liability Company

Andeavor Limited Liability Company

Citgo Petroleum Corporation

Citgo Petroleum Corporation

Tesoro Corporation

Tesoro Corporation

Some of the leading companies in the petroleum and coal products manufacturing in Canada:

Suncor Energy Incorporated

Suncor Energy Incorporated

Imperial Oil Limited

Imperial Oil Limited

Husky Energy Incorporated

Husky Energy Incorporated

Shell Canada Limited

Shell Canada Limited

Irving Oil Limited

Irving Oil Limited

Cenovus Energy Incorporated

Cenovus Energy Incorporated