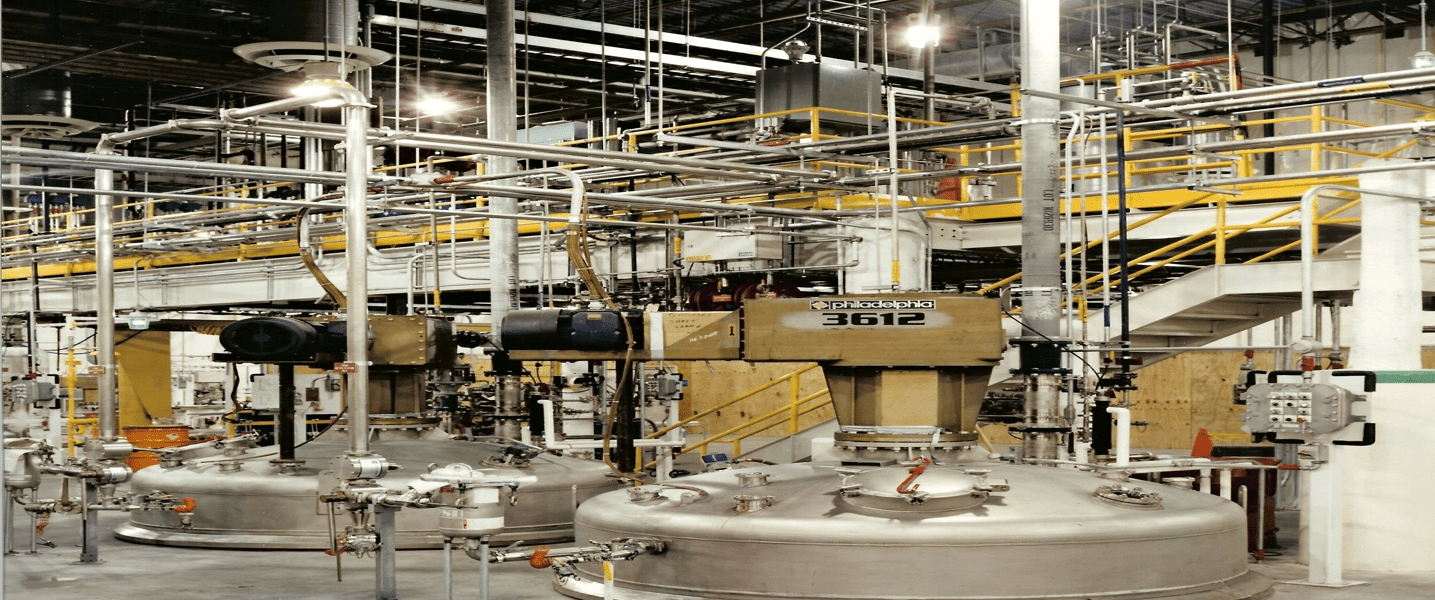

Coatings and resins manufacturing is a sub-industry of the chemicals sector that produces various types of coatings and resins for multiple applications. These products enhance the properties of surfaces and resist wear and tear. Coatings and resins manufacturing refers to the production of coatings, such as paints and varnishes, and resins, including epoxy and polyurethane resins. These products have a wide range of physical and chemical properties that enhance the properties of surfaces and provide resistance to wear and tear in various industries and applications.

GAO RFID Inc., one of the top 10 RFID companies in the world, is headquartered in Toronto and New York and has implemented numerous IoT, BLE, and RFID projects in the coatings and resins manufacturing industry.

GAO RFID Systems & Hardware for the Coatings and Resins Manufacturing Construction

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the coatings and resins manufacturing construction industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humidity, vibration, and panic button:

- IP67 Rated BLE 2.45GHz Active RFID Wristband Tag w/ Panic Button

- BLE 2.45GHz Ultra Rugged Active RFID Pallet Tag/Beacon

- BLE 2.45GHz Active RFID Asset Tag/Beacon

GAO’s BLE technology is suitable for all kinds of industries, including the coatings and resins manufacturing construction industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the coatings and resins manufacturing construction industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the coatings and resins manufacturing construction industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the coatings and resins manufacturing construction industry:

- 134.2KHz ISO11784/5 FDX RFID Plug and Play Portable Reader

- 134.2 kHz LF Long Range Fixed RFID Reader

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the coatings and resins manufacturing construction industry:

and antennas:

GAO also offers RFID printers, Digital I/O adapters and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the coatings and resins manufacturing construction industry:

People or workers tracking system:

Physical asset or operational equipment tracking system:

Personnel or people access control system:

Parking or vehicle control system:

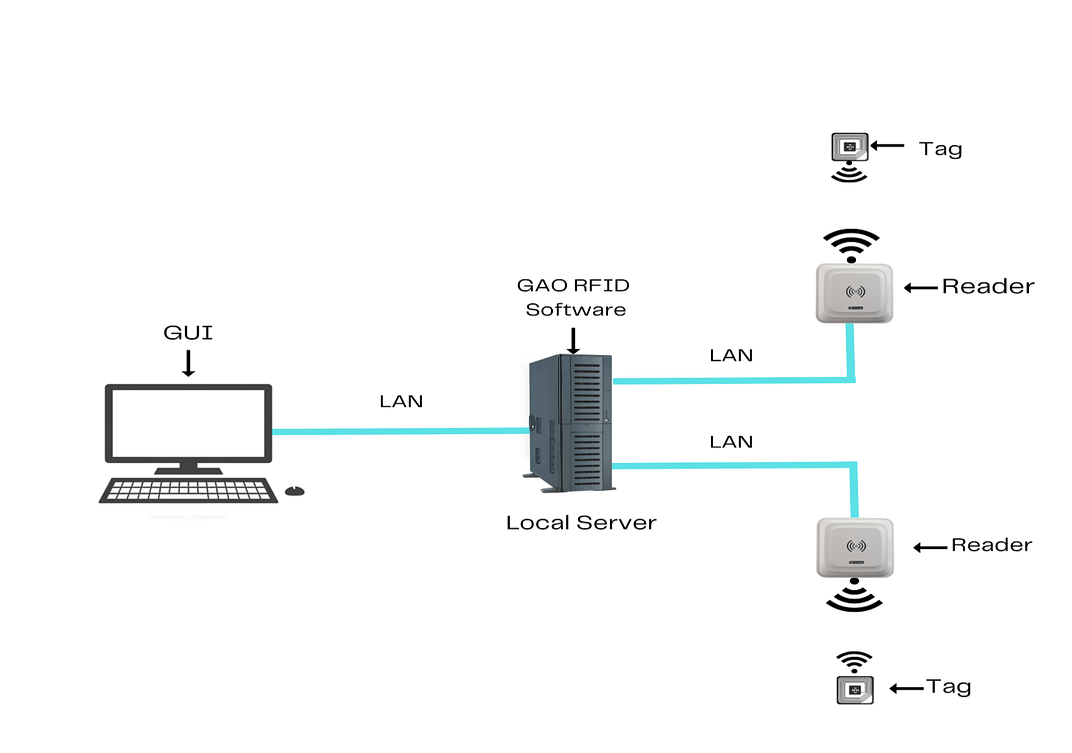

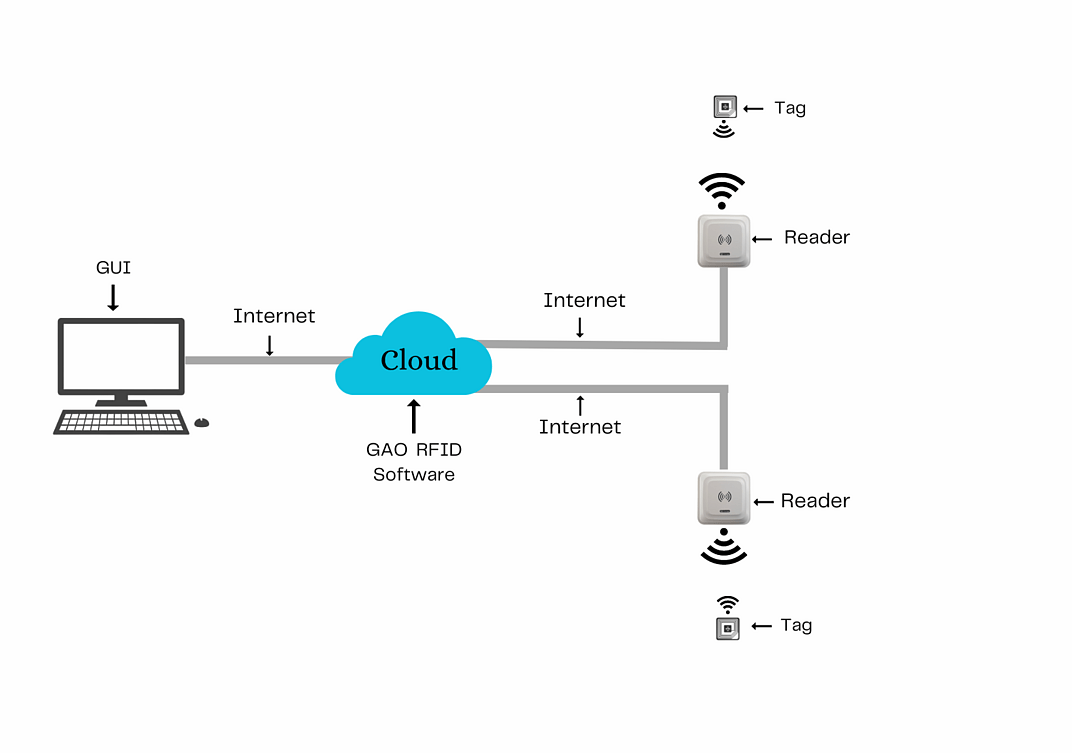

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

GAO’s software runs on a local server

GAO’s software runs on a local server

GAO’s software runs in the cloud

GAO’s software runs in the cloud

GAO offers free samples of its RFID tags, labels, badges, and wristbands.

GAO offers a free trial for all of its software available.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones Coatings and Resins Manufacturing

RFID, BLE, IoT and drones technologies from GAO RFID Inc. offer many benefits for the coatings and resins manufacturing

Application & benefits of applying RFID to coatings and resins manufacturing:

- Improved inventory management: GAO’s RFID tags can be used to track and monitor the movement of raw materials and finished goods helping to reduce errors, prevent stockouts, and ensure that the right materials are available at the right time.

- Enhanced operational efficiency: Our RFID products can automate several manual processes, including inventory tracking and asset management, reducing the time and effort required for these tasks and allowing employees to focus on higher-value activities.

- Increased transparency: Our RFID tags provides real-time data that can be used to optimize production processes and identify areas for improvement, helping to increase transparency and drive continuous improvement.

Application & benefits of applying BLE to coatings and resins manufacturing:

- Real-time monitoring: Our BLE-enabled sensors may be used to track assets and monitor mixing machines, reactors, conveyors, and storage tanks in real-time, making it easier to spot problems, cut down on downtime, and better plan maintenance.

- Workflow efficiency: GAO’s BLE beacons can be put at various points around the production facility to track the movement of workers and goods, enhancing workflow effectiveness and lowering mistakes.

- Quality control: Our BLE sensors can be used to monitor environmental factors like temperature and humidity, making sure that supplies and goods are stored properly and in accordance with specifications.

Application & benefits of applying combination of RFID and loT to coatings and resins manufacturing:

- Predictive maintenance: Combination of RFID with IoT sensors can be used to monitor equipment performance, and our RFID tags can track maintenance history, enabling predictive maintenance and reducing downtime.

- Enhanced supply chain visibility: Our RFID tags and IoT sensors can be used to track the movement of materials and products throughout the supply chain, providing real-time visibility and improving coordination.

- Improved quality control: IoT sensors can collect data on environmental conditions such as temperature and humidity, and RFID tags can track the production process, enabling better quality control and preventing defects.

Applications & benefits of applying combination of RFID and drones coatings and resins manufacturing:

- Rapid asset tracking: Drones equipped with our RFID readers can quickly locate assets such as mixing tanks, processing vessels, reactors, pumps, valves, and pipes reducing the time and effort required for manual tracking.

- Enhanced safety: Drones can be used to inspect facilities and equipment, identifying potential safety hazards, and reducing the risk of accidents.

- Improved quality control: Drones can be used to capture high-resolution images and videos, enabling detailed inspections, and improving quality control.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Coatings and Resins Manufacturing

GAO RFID Inc. has assisted numerous companies in the Coatings and Resins Manufacturing industry with the deployment of RFID systems, ensuring that such deployments conform to relevant industry standards, mandates, and governmental regulations:

- Occupational Safety and Health Administration (OSHA): Regulations governing workplace safety, including the handling of hazardous materials and the use of personal protective equipment.

- RPM International: A holding company that owns a variety of subsidiaries engaged in the production of coatings, sealants, and other specialty chemicals. RPM’s subsidiaries serve a range of industries, including construction, industrial, and consumer markets.

- Benjamin Moore: A manufacturer of premium paints and coatings for residential and commercial applications. Benjamin Moore’s products are known for their quality and durability and are available through a network of independent retailers and distributors.

- Environmental Protection Agency (EPA): Regulations governing the handling and disposal of hazardous waste, including waste generated in the manufacturing process.

- Food and Drug Administration (FDA): Regulations governing the use of coatings and resins in food packaging and other consumer products, including requirements for product labeling and safety testing.

- Canadian Environmental Protection Act (CEPA): Regulations governing the handling and disposal of hazardous waste, including waste generated in the manufacturing process.

- Canadian Centre for Occupational Health and Safety (CCOHS): Regulations governing workplace safety, including the handling of hazardous materials and the use of personal protective equipment.

Occupational Safety and Health Administration

Occupational Safety and Health Administration

Canadian Centre for Occupational Health and Safety

Canadian Centre for Occupational Health and Safety

Food and Drug Administration (FDA)

Food and Drug Administration (FDA)

Environmental Protection Agency

Environmental Protection Agency

Benjamin Moore & Co.

Benjamin Moore & Co.

Canadian Environmental Protection Act

Canadian Environmental Protection Act

GAO’S Software Provides API

GAO’s popular RFID software such as personnel tracking, asset tracking. access control, parking system control, work-in-progress offers a free trial and offers an API to each of the common software in the coatings and resins manufacturing industry:

Personnel Management

- Time and Attendance Management System: Helps businesses track and manage employee attendance, work hours, and related data.

- Performance Management System: A set of tools to measure, evaluate, and improve employee performance within an organization.

Equipment Management

- Equipment Maintenance Management: Organizes, plans, schedules, and executes maintenance activities on heavy equipment and machinery to ensure efficient functioning.

- Asset Tracking: Tracks the location of heavy equipment, monitors usage, and prevents theft.

- Equipment Rental Management: Helps schedule maintenance, track repair history, and generate reports on equipment maintenance.

Supply Chain Management

- Procurement: Manages the procurement process by tracking supplier performance, identifying cost-saving opportunities, and automating purchase orders.

- Logistics: Optimizes logistics operations by tracking delivery schedules, managing inventory levels, and coordinating transportation.

- Supplier Management: Manages supplier relationships by tracking performance metrics, facilitating communication, and ensuring compliance with contractual agreements.

- Risk Management: Mitigates risks by identifying potential disruptions, creating contingency plans, and implementing risk management strategies.

Other Applications

- Access Control System: Manages access to secure areas of job sites, including controlling access to heavy equipment and vehicles.

- Waste Management System: Tracks the movement of waste and recycling materials on job sites, including providing data on waste volume and disposal methods.

Case Studies of RFID Applications

A case study of RFID application in the coatings and resins manufacturing industry in the U.S.:

AkzoNobel Coatings implemented RFID to track their raw materials and finished products. The RFID solution included tags on each container and readers at various points in the production process, providing real-time data on the location and status of materials. This enabled AkzoNobel to make informed decisions and improve production efficiency, reducing inventory and improving customer service by providing accurate and timely information about order status.

Here is another case study of PPG Industries implemented RFID to improve inventory management and production efficiency. Our RFID solution included tags on each container and readers at various points in the production process, providing real-time data on the location and status of materials. This enabled PPG to make informed decisions, improving production efficiency and reducing inventory. Customers also benefited from improved customer service, receiving accurate and timely information about order status.

GAO Has Served Coatings and Resins Manufacturing Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in the coatings and resins manufacturing industry, including its various divisions such as

- Architectural coatings: These coatings are used for residential and commercial construction, such as paints, varnishes, and stains.

- Industrial coatings: These coatings are used in various industries, including automotive, aerospace, and marine, and are designed to provide protection from corrosion, wear and tear, and weathering.

- Powder coatings: These coatings are applied as a dry powder and then heated to form a durable, smooth finish. They are commonly used in appliances, electronics, and automotive parts.

- Adhesives and sealants: These products are used to bond materials together or to fill gaps and cracks in surfaces, such as in construction or automotive applications.

- Resins: Resins are used in various applications, including adhesives, coatings, and composites. Some common types of resins include epoxy, polyester, and polyurethane resins.

- Wood coatings: used to protect and enhance the appearance of wood products, such as furniture, cabinetry, and flooring. Wood coatings may include stains, varnishes, and lacquers.

Leading companies in Coatings and Resins manufacturing in the U.S.:

Akzo Nobel N.V

Akzo Nobel N.V

Axalta Coating Systems

Axalta Coating Systems

RPM International Inc.

RPM International Inc.

Valspar Corporation

Valspar Corporation

BASF SE Company

BASF SE Company

Arkema S.A Company

Arkema S.A Company

Dow Inc.

Dow Inc.

Eastman Chemical Company

Eastman Chemical Company

Dunn-Edwards Corporation

Dunn-Edwards Corporation

3M company

3M company

Jotun Paints Company

Jotun Paints Company

Diamond Vogel Paints Inc.

Diamond Vogel Paints Inc.

Ameron International Corporation

Ameron International Corporation

Hentzen Coatings, Inc.

Hentzen Coatings, Inc.

Hempel USA Inc.

Hempel USA Inc.

Rust-Oleum Corporation

Rust-Oleum Corporation

Tnemec Company

Tnemec Company

Axson US Inc.

Axson US Inc.

List of the leading companies in heavy construction in Canada:

Cloverdale Paint Inc.

Cloverdale Paint Inc.

Canlak Inc.

Canlak Inc.

General Paint Co.

General Paint Co.

Elite Protective Coatings Company

Elite Protective Coatings Company

PPG Industries, Inc.

PPG Industries, Inc.

Sherwin-Williams Company

Sherwin-Williams Company