The electronic instrument manufacturing industry is critical to supporting multiple industries, from healthcare to aerospace. Manufacturing electronic instruments demands specialized equipment and expertise for precision and accuracy. Technological advancements drive growth and competitiveness, leading to constant research and development investment to meet evolving customer needs. With rising demand in various industries, the industry’s growth is expected to continue. Adaptability to changing markets and technology will position companies for success in this dynamic sub-industry.

GAO RFID Inc., one of the top 10 RFID companies in the world, is headquartered in Toronto and New York and has implemented numerous IoT, BLE, and RFID projects in the electronic instrument manufacturing industry

GAO RFID Systems & Hardware for the Electronic Instrument Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including the electronic instrument manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humidity, vibration, and panic button:

- IP67 Rated BLE 2.45GHz Active RFID Wristband Tag w

- BLE 2.45GHz Ultra Rugged Active RFID Pallet Tag

- BLE 2.45GHz Active RFID Asset Tag/Beacon

GAO’s BLE technology is suitable for all kinds of industries, including the electronic instrument manufacturing industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the electronic instrument manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the electronic instrument manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the electronic instrument manufacturing industry:

- 134.2KHz ISO11784/5 FDX RFID Plug and Play Portable Reader

- 134.2 kHz LF Long Range Fixed RFID Reader

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the electronic instrument manufacturing industry

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the electronic instrument manufacturing industry:

People or workers tracking system:

Physical asset or operational equipment tracking system:

- GAO RFID Construction and Industrial Machinery Rental Asset Management System

- Gen2 UHF 902-928 MHz Passive RFID Readers

- Gen 2 UHF 865-868 MHz Passive RFID Readers

Personnel or people access control system:

Parking or vehicle control system:

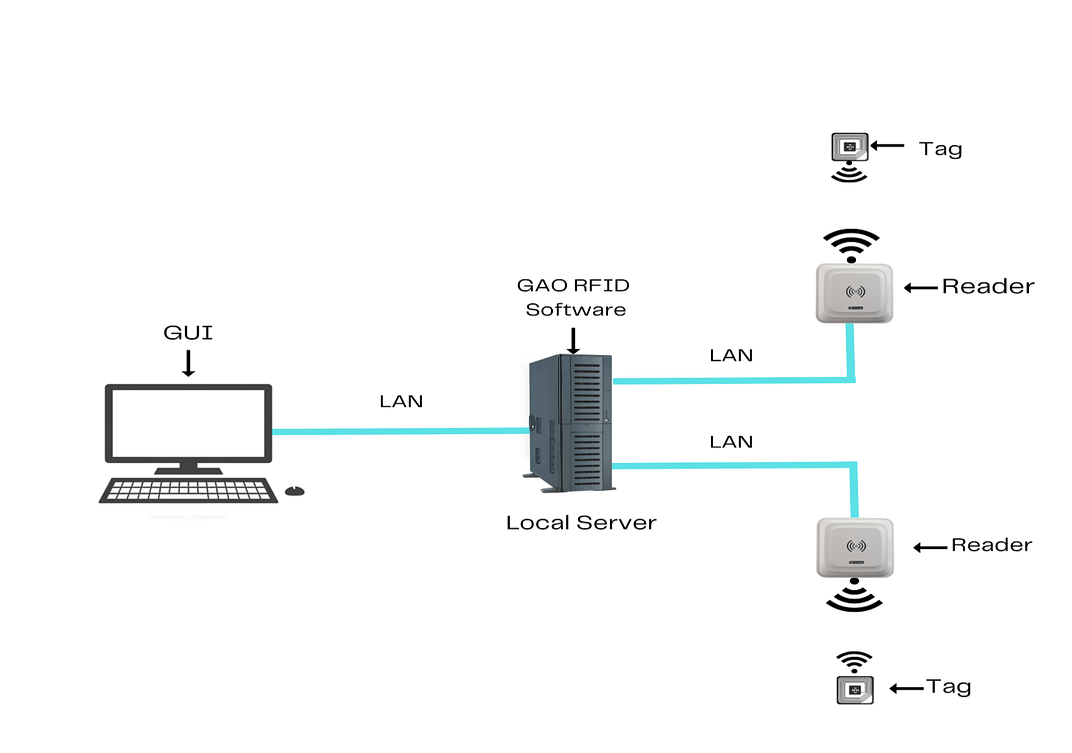

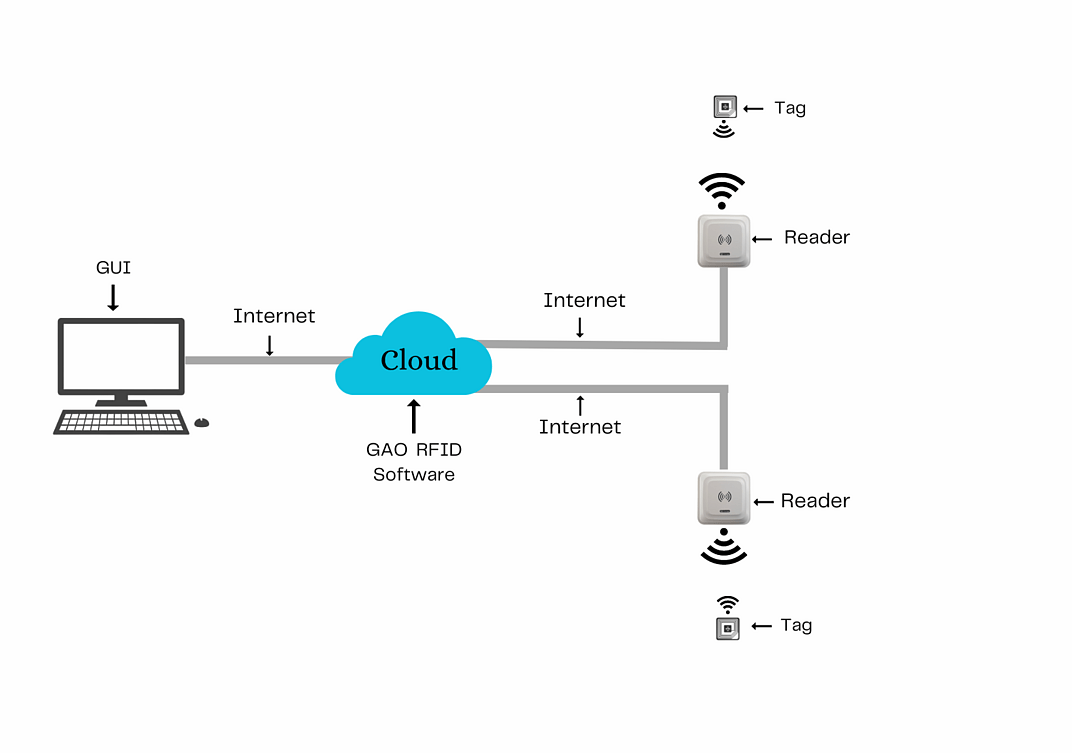

There are two versions of GAO’s software, one is running on a local server, and another running in the cloud.

GAO’s software runs on a local server

GAO’s software runs on a local server

GAO’s software runs in the cloud

GAO’s software runs in the cloud

GAO offers free samples of its RFID tags, labels, badges, and wristbands.

GAO offers a free trial for all of its software available.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones Electronic Instrument Manufacturing

RFID, BLE, IoT and drone technologies from GAO RFID Inc offer many benefits for the electronic instrument manufacturing

Application & benefits of applying RFID to electronic instrument manufacturing

- Inventory management: Our RFID technology can help track and manage inventory levels accurately and efficiently. It enables companies to monitor their stock levels in real-time, reducing the risk of stock-outs and overstocking.

- Asset tracking: Electronic instrument manufacturers can use RFID tags to track their assets, such as CNC machines, lathes, drills, and equipment like oscilloscopes, signal generators, and spectrum analyzers. This allows companies to know the exact location of their assets, monitor usage, and prevent theft or loss.

- Quality control: GAO’s RFID tags can be attached to electronic instruments such as electronic chips, sensors, and components during the manufacturing process. This helps to ensure that the correct components are used, and each product is tested and verified according to the company’s standards.

Application & benefits of applying BLE to electronic instrument manufacturing

- Energy management: Our BLE can be used to control and optimize the energy consumption of electronic instruments, reducing costs and improving efficiency.

- Productivity improvement: GAO’s BLE technology can be used to automate processes and workflows, reducing manual labor, and improving productivity.

- Enhanced customer service: Our BLE technology can be used to provide better customer service. By remotely monitoring products, manufacturers can provide customers with accurate information about the status of their orders, delivery dates, and other details.

Application & benefits of applying combination of RFID and loT to electronic instrument manufacturing

- Predictive maintenance: Our RFID technology combined with IoT sensors can be used to monitor the performance of electronic instruments, and to track their usage and history. This allows manufacturers to predict when maintenance is needed and perform it proactively, reducing downtime and increasing efficiency.

- Logistics: GAO’s RFID tags can be used to track electronic instruments such as turbines, generators, and transformers throughout the manufacturing process, and IoT sensors can be used to monitor their performance and quality. This allows companies to ensure that each product meets their standards and identify potential issues early.

- Supply chain management: Our RFID technology can be used to track products throughout the supply chain, and IoT sensors can be used to monitor the condition of products during transit. This allows manufacturers to optimize their supply chain operations, reduce lead times, and improve efficiency.

Application & benefits of applying combination of RFID and drones to electronic instrument manufacturing

- Preventive maintenance: Drones equipped with sensors and cameras can perform preventive maintenance inspections on electronic instruments such as solar panels and inverters. RFID technology tracks maintenance history, allowing companies to predict maintenance needs and perform it proactively. This reduces downtime and increases efficiency.

- Asset tracking: Our RFID technology can be used to track assets, and drones can be used to locate and retrieve them. This allows manufacturers to optimize asset usage, prevent loss or theft, and reduce manual labor.

GAO Helps Customers Comply with Standards, Mandates & Regulations of Drones to Electronic Instrument Manufacturing

GAO RFID Inc. has assisted numerous companies in the electronic instrument manufacturing industry with the deployment of RFID systems, ensuring that such deployments conform to relevant industry standards, mandates, and governmental regulations:

- The Federal Communications Commission (FCC): The FCC regulates the use of RFID devices in the US. Companies must ensure that their RFID systems comply with FCC regulations related to power output and frequency range.

- The US Health Insurance Portability and Accountability Act: HIPAA regulates the use of RFID technology in the healthcare industry. Companies must comply with HIPAA regulations related to privacy and security when using RFID to track patient information or medical devices.

- The Canadian Food Inspection Agency (CFIA): The CFIA regulates the use of RFID technology in the food industry in Canada. Companies must comply with CFIA regulations related to traceability and labeling when using RFID to track food products.

- The Canadian Radio-television and Telecommunications Commission: The CRTC regulates the use of RFID devices in Canada. Companies must ensure that their RFID systems comply with CRTC regulations related to power output and frequency range.

- The US National Institute of Standards and Technology: NIST has issued guidelines for the use of RFID technology in supply chain management. These guidelines provide best practices for ensuring the security and privacy of RFID systems.

- Transport Canada regulations: Transport Canada regulates the use of RFID technology in the transportation industry in Canada. Companies must comply with Transport Canada regulations related to safety and security when using RFID to track vehicles or cargo.

- The US Food and Drug Administration: The FDA requires medical device manufacturers to include a UDI on their products, which can be tracked using RFID technology.

- The Electronic Product Code: EPC Gen2 standard is used in the retail supply chain and was developed by GS1, an international standards organization. The use of EPC RFID is mandated by several large retailers in the United States, including Walmart and Target.

Food and Drug Administration

Food and Drug Administration

The Electronic Product Code

The Electronic Product Code

The Federal Communications Commission

The Federal Communications Commission

The US National Institute of Standards and Technology

The US National Institute of Standards and Technology

The Canadian Radio-television and Telecommunications Commission

The Canadian Radio-television and Telecommunications Commission

The US Health Insurance Portability and Accountability

The US Health Insurance Portability and Accountability

GAO’S Software Provides API

GAO’s popular RFID software such as personnel tracking, asset tracking. access control, parking system control, work-in-progress offers a free trial and offers an API to each of the common software in the electronic instrument manufacturing industry

Personnel Management:

- Human Resource Management System: Used to manage recruitment, track employee attendance, handle payroll, and provide training and development activities.

- Time and Attendance Management System: Helps businesses track and manage employee attendance, work hours, and related data.

- Performance Management System: A set of tools to measure, evaluate, and improve employee performance within an organization.

Equipment Management:

- Equipment Maintenance Management: Organizes, plans, schedules, and executes maintenance activities on heavy equipment and machinery to ensure efficient functioning.

- Asset Tracking: Tracks the location of heavy equipment, monitors usage, and prevents theft.

- Equipment Rental Management: Helps schedule maintenance, track repair history, and generate reports on equipment maintenance.

Supply Chain Management:

- Procurement: Manages the procurement process by tracking supplier performance, identifying cost-saving opportunities, and automating purchase orders.

- Logistics: Optimizes logistics operations by tracking delivery schedules, managing inventory levels, and coordinating transportation.

- Inventory Management: Helps manage inventory levels, track usage rates, and forecast demand to ensure the right amount of inventory at the right time.

- Supplier Management: Manages supplier relationships by tracking performance metrics, facilitating communication, and ensuring compliance with contractual agreements.

- Risk Management: Mitigates risks by identifying potential disruptions, creating contingency plans, and implementing risk management strategies.

Other Applications:

- Access Control System: Manages access to secure areas of job sites, including controlling access to heavy equipment and vehicles.

- Waste Management System: Tracks the movement of waste and recycling materials on job sites, including providing data on waste volume and disposal methods.

Case Studies of RFID Applications

A case study of RFID application in Electronic Instrument Manufacturing Industry in the US:

Texas Instruments, a semiconductor manufacturer, implemented an RFID-based asset tracking system to monitor its capital equipment inventory. The system uses RFID tags to track asset location and movement, and an RFID reader network to collect data. The system provides real-time information on equipment utilization, generates automated alerts for preventive maintenance, and minimizes the risk of lost or stolen assets. This has helped Texas Instruments to improve efficiency, reduce downtime, and enhance its asset management capabilities. By leveraging the power of RFID technology, Texas Instruments has gained valuable insights into the utilization of its equipment, allowing the company to optimize its assets and minimize waste. The RFID-based asset tracking system has enabled Texas Instruments to achieve greater efficiency and accuracy in its asset tracking processes, driving innovation and improving performance in the electronic instrument manufacturing industry.

Another case study of RFID application in Electronic Instrument Manufacturing Industry in the US:

International Business Machines a technology company based in Armonk, New York, implemented an RFID-based inventory management system at its semiconductor manufacturing plant in East Fishkill, New York. The system uses RFID tags to track the movement of inventory items throughout the manufacturing process, providing real-time visibility into inventory levels and location. This allows IBM to reduce the risk of stockouts and excess inventory and optimize its manufacturing processes. The system also improves the accuracy of inventory records, reducing errors and improving the efficiency of inventory management.

GAO Has Served Electronic Instrument Manufacturing Extensively

GAO RFID Inc., a global top 10 leader in RFID, has served many leading companies in the electronic instrument manufacturing industry, including its various divisions such as:

- Medical instruments: It produces a variety of electronic instruments used in medical applications such as patient monitoring, diagnostic imaging, and surgical procedures.

- Test and measurement instruments: This sub-industry produces electronic instruments used to measure, analyze, and test a variety of parameters such as voltage, current, frequency, and temperature.

- Control and automation instruments: They produce electronic instruments used in process control and automation applications such as industrial control systems, robotics, and home automation.

- Navigation and communication instruments: This sub-industry produces electronic instruments used in navigation and communication applications such as GPS devices, radios, and radar systems.

- Defense and aerospace instruments: This industry produces electronic instruments used in defense and aerospace applications such as aircraft avionics, missile guidance systems, and satellite communication systems.

- Electronic musical instruments: This sub-industry produces electronic instruments used in music production, performance, and recording applications such as synthesizers, electronic keyboards, and digital audio workstations.

List of the leading companies in Electronic Instrument Manufacturing in the U.S

Keysight Technologies Inc.

Keysight Technologies Inc.

Agilent Technologies Inc

Agilent Technologies Inc

Tektronix Inc

Tektronix Inc

Fluke Corporation

Fluke Corporation

National Instruments Corporation

National Instruments Corporation

Emerson Electric Co.

Emerson Electric Co.

Honeywell International Inc

Honeywell International Inc

General Electric Company

General Electric Company

Texas Instruments Inc

Texas Instruments Inc

Analog Devices Inc

Analog Devices Inc

Thermo Fisher Scientific Inc

Thermo Fisher Scientific Inc

Danaher Corporation

Danaher Corporation

AMETEK, Inc

AMETEK, Inc

Bruker Corporation

Bruker Corporation

L3Harris Technologies, Inc

L3Harris Technologies, Inc

FLIR Systems, Inc

FLIR Systems, Inc

Keysight Technologies Inc.

Keysight Technologies Inc.

Teradyne Inc.

Teradyne Inc.

List of the leading companies in Electronic Instrument Manufacturing in Canada

Teledyne DALSA Inc

Teledyne DALSA Inc

FLIR Systems Inc

FLIR Systems Inc

Mitutoyo Canada Inc

Mitutoyo Canada Inc

Keysight Technologies Canada ULC

Keysight Technologies Canada ULC

Honeywell International Inc

Honeywell International Inc

Thermo Fisher Scientific Inc

Thermo Fisher Scientific Inc