Accurate, Time Saving & Effective Asset Management Solution

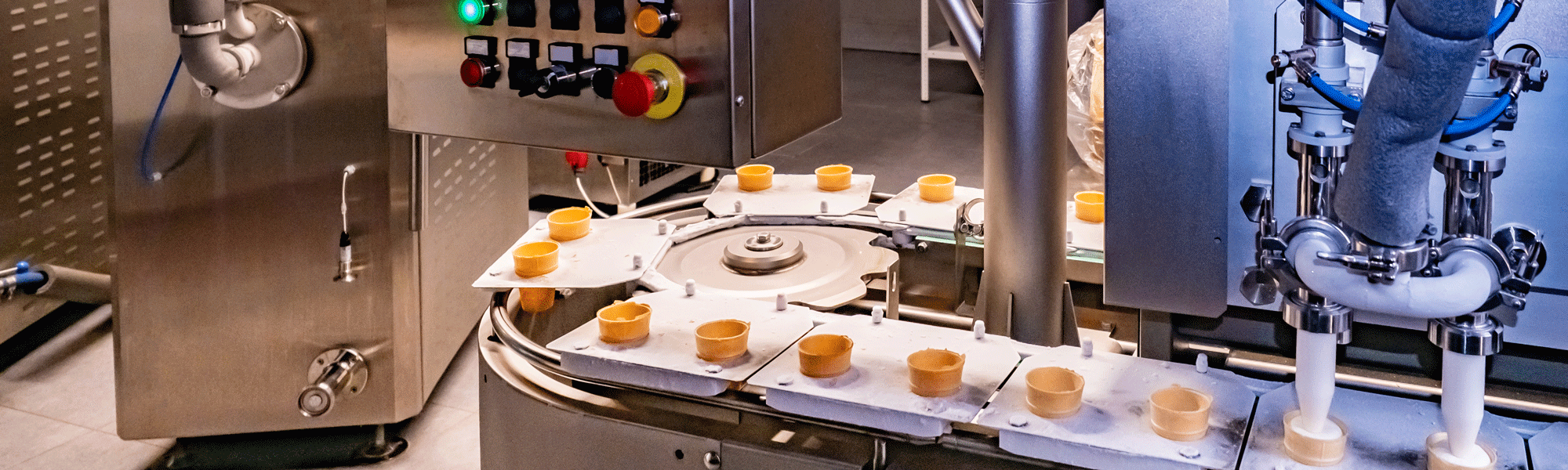

With this RFID solution, the asset management of your ice cream and frozen dessert factory can be done simply by having an employee walk through the facility while holding a handheld computer with an RFID reader, which tracks the tagged assets.

For more technical details, please visit the GAO RFID Ice Cream and Frozen Dessert Manufacturing System page on our website.

What the GAO RFID Ice Cream and Frozen Dessert Manufacturing Asset Management System Tracks

Our RFID system can track all ice cream and frozen dessert manufacturing assets including:

- Freezers

- Ingredient freezers, storage freezers and other freezers

- Extrusion equipment

- Fillers

- Molding equipment

- Wrappers

- Packing equipment

- Pasteurizers

- Dollys, trucks & carts

- All other assets your ice cream and frozen dessert facility may utilize

Applications of the GAO RFID Ice Cream and Frozen Dessert Manufacturing Asset Management System

The GAO RFID Ice Cream and Frozen Dessert Manufacturing Asset Management System can be scaled to fit the needs of ice cream and frozen dessert facilities of various sizes, small or large.

There are all kinds of ice cream and frozen dessert facilities, and they may produce large varieties of desserts including:

- Snow cones, ice pops, sorbet, shaved ice and more

- Frozen custard, frozen souffle and frozen yoghurt

- Semifreddos and gelato

- Mellorine

- Flavoured ice cream

- Other cold and sweet foods that are included in the ice cream and frozen dessert category.

The GAO RFID Ice Cream and Frozen Dessert Manufacturing Asset Management System is well suited to track the assets of all sizes of manufacturers whether you are small specialty manufacturer or a large commercial sized organization.

LEARN MORE ABOUT THIS SYSTEM!

Click here to get detailed specifics of how this system will work.

Request a quote or speak to one of our RFID experts

to see how this system WILL save you time & money

The Ice Cream and Frozen Dessert Industry

Ice cream and frozen desserts are manufactured by private businesses for the sake of selling said products for consumption by consumers and the general population. Most businesses tend to manufacture ice cream instead of frozen desserts, as ice cream tends to be more appealing and therefore popular to the public. In fact, the great demand for ice cream in the Cuban community, led former Prime Minister Fidel Castro to open a separate market in the country dedicated solely to the ice cream business. However, other frozen desserts are now gaining in popularity due to the current rising trend of veganism, as these desserts generally do not contain any animal by-products.

The difference between ice cream and frozen desserts is the variation between the types of fat contained in both. Ice cream uses milk fat, whereas frozen desserts use vegetable fat. Ice cream also tends to be more solid than frozen desserts, as the latter are typically made from flavored water of juice.

The ingredients for both ice cream and frozen desserts are sourced in ice cream and/or frozen dessert factories. Ice cream ingredients are obtained from the dairy industry, while frozen dessert ingredients are acquired from farms and the water industry.

From a general standpoint, it seems that frozen desserts may eventually take over ice cream in monetary value due to the rising trend of veganism. However, after taking a closer look, it becomes apparent that both industries will likely result in a market stalemate due to new dairy alternatives being developed, which may be used in ice cream as a substitute for dairy products. In catering to public demand, both industries have now begun to produce products in higher numbers, which are not only of a superior quality, but also offer more variety, including an increasing assortment of flavors. The evolution of technology brings with it new ways of selling frozen delicacies, such as ordering food online. The prevalence of these newer methods increases the value of ice cream and frozen desserts even more within the market. This steady rise is predicted to continue as technology evolves further and populations increase in size.

According to Mordor Intelligence, the revenue for ice cream and frozen desserts is about $212 billion worldwide, with an estimated $20+ billion coming from North America. While an exact percentage of consumers has not been documented, there is data for the amount of liters of frozen desserts consumed, with North America reportedly consuming approximately 50 liters per capita.

Ice cream and frozen dessert manufacturers can be found in large numbers across North America, with San Francisco in the U.S. and Vancouver in Canada being the biggest producers. Other cities in the U.S. which run large-scale ice cream and frozen dessert manufacturing businesses include Seattle, New York, Los Angeles and San Diego, while in Canada the highest number of manufacturers operate in cities like Calgary, Toronto and Montreal.

RFID Systems for Frozen Food Manufacturing

- Tagging and thereby protecting inventory and stock from theft

- Maintaining accurate tags on assets as they undergo processing in your supply chain

- Allowing you to collect data on the maintenance and repairs of heavy equipment as needed

- Eliminate lag times among processes and reduce cycle times for streamlined product movement

- Secure your premises

Radio frequency identification technology (RFID) is a revolutionary enabler of automated data capture that is especially beneficial to the manufacturing industry. The use of RFID technology is a vehicle to achieve leaner manufacturing through automated data collection, assurance of data dependencies, and greater inventory visibility.

Using GAO RFID Systems in the Frozen Food Manufacturing Industry

With GAO’s RFID Systems, you will notice a reduction in product and process errors. As the industry landscape gets increasingly competitive, plant managers are required to find new ways to make production more efficient while being cautious of keeping costs low. Designed for ease of use and adaptable to numerous situations, our RFID Systems provide the benefits listed below: Analyze Supply Chain Processes Overseeing the movement of a tagged asset as it undergoes processing in your supply chain allows you to obtain data related to the efficiency of this operation. Real-time data pulled from uniquely identified products allows you to reduce the amount of human supervision or human intervention needed to monitor these operations. Easily determine location, condition, and history of a designated piece of product anywhere in your supply chain. This gives you unparalleled visibility an enables you to make important inventory decisions that keep your operations lean. Maintain Security at All Times The advantages of real-time data accessible at any time of day allows you supervision over your property unlike ever before. Security can be upheld effectively through a) implanting RFID Tags on existing equipment and machinery, and b) ensuring that your employees are adequately tracked with RFID traceable identification cards. Our Asset Tracking and Personnel Tracking Systems ensure that you are notified if there ever is removal of property or an authorized attempt at accessing your facility. Manage a Equipment Maintenance Schedules Our Asset Tracking System automatically notifies you when your equipment is in need of maintenance. This will reduce the amount of human intervention needed as well as the time spent on paperwork that can now be spent elsewhere and ultimately keep your equipment running and ensure production uptime. In addition, every time service is performed, the history is recorded onto the RFID Tag so that an electronic paper trail follows the equipment so that it is clear what work has been done to each equipment and reduces duplicate fixes and streamlines troubleshooting.

Integrating our RFID System with your Existing Management Software

GAO RFID’s Systems can be deployed as a standalone solution or can be integrated with other software solutions, according to your needs. At the core of our solution is GAO RFID’s AUTO-ID Engine which incorporates middleware and essential RFID functions that perform RFID data collection and information processing. Our AUTO-ID Engine seamlessly integrates with a wide variety of management systems so that you can access the data it collects directly via the system or systems you currently have in place. Our team of seasoned professionals will smoothly integrate the appropriate GAO RFID Solution with your IT architecture. The result is an RFID solution that is seamlessly unified with your management system. Contact us for more information on how our RFID Systems can be configured for your organization.