Overview

The Commercial Vehicle Manufacturing Industry designs, produces, and distributes vehicles intended primarily for commercial use. These vehicles, such as trucks, buses, and vans, serve purposes like transporting goods and passengers. The industry caters to diverse clients like logistics companies and governments, customizing vehicles to meet specific needs. It incorporates technological advancements for safety and efficiency, adheres to regulations, operates globally, and focuses on sustainability. The industry’s innovations include alternative fuels and electric vehicles, contributing to economies through job creation and revenue generation.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in Spring and Wire Product Manufacturing Industry to improve their work processes, their operations and productivity by better management of their staff, materials and operational equipment such as Welding Robots, CNC Machines, Presses, Paint Booths, Assembly Lines, Hydraulic Presses, Laser Cutting Machines, Robotic Arm Systems, Metal Stamping Equipment, Material Handling Systems, Inspection and Testing Equipment, Automated Guided Vehicles (AGVs), Injection Molding Machines, Powder Coating Equipment, Welding Fixtures, Plasma Cutting Machines, Riveting Machines, CNC Plasma Cutters, Tube Bending Machines, Soldering Stations.

Ranked as a top 10 global RFID supplier and based in New York City and Toronto, GAO RFID Inc offers a wide choice of RFID (radio frequency identification) readers and tags at ultra high frequency (UHF), high frequency (HF, including NFC) and low frequency (LF), BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems, together with its IoT and drone technologies, have been widely used in Spring and Wire Product Manufacturing. Its sister company, GAO Tek Inc. https://gaotek.com, is a leading supplier of industrial or commercial testers and analyzers, drones, and network products.

The targeted markets of both GAO RFID Inc. and GAO Tek Inc. are North America, particularly the U.S., Canada, Mexico, and Europe. As a result, this website gaorfid.com is offered in English and other major languages of North America and Europe such as Spanish, French, German, Italian, Polish, Ukrainian, Romanian, Russian, Dutch, Turkish, Greek, Hungarian, Swedish, Czech, Portuguese, Serbian, Bulgarian, Croatian, Danish, Finnish, Norwegian, Slovak, Catalan, Lithuanian, Bosnian, Galician, Slovene, Latvian, Estonian, Welsh, Icelandic, and Irish.

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for Commercial Vehicle Manufacturing Industry

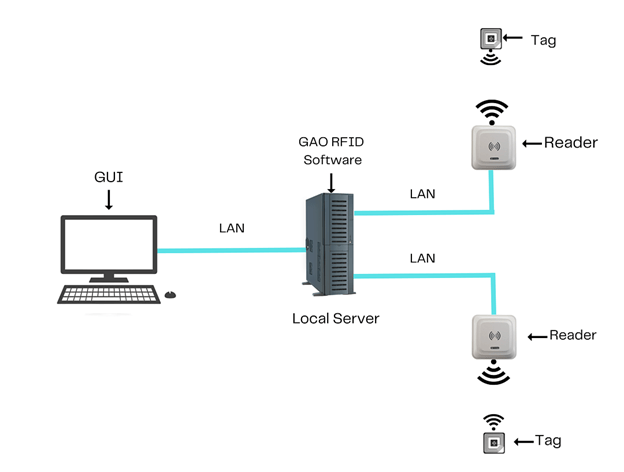

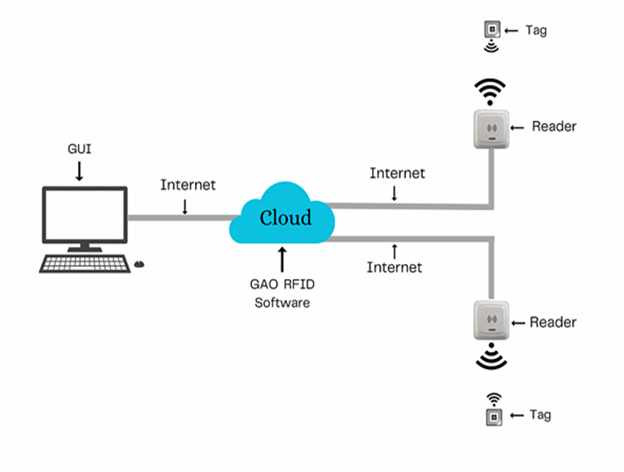

To satisfy its customers, GAO’s RFID or RFID Systems for Spring and Wire Product Manufacturing are offered in 2 versions. One version is that its software is running on a local server that normally is on our client’s premise, and another version runs in the cloud. The cloud server could be GAO’s cloud server, client’s own cloud server or a cloud server from one of the leading cloud server providers such as Amazon Web Services (AWS), Microsoft Azure, Google Cloud, IBM Cloud (formerly SoftLayer), Oracle Cloud, RedHat, Heroku, Digital Ocean, Cloud Flare, Lin ode and Rackspace. The above illustrates GAO system for Commercial Vehicle Manufacturing Industry Spring and Wire Product Manufacturing software running on a local server.

The above illustrates GAO system for Commercial Vehicle Manufacturing Industry with its software running in cloud.

GAO’s RFID and BLE technologies, consisting of RFID readers, RFID tags, BLE gateways, BLE beacons, software, cloud services and their systems, have the following applications in Commercial Vehicle Manufacturing Industry:

- Inventory Management: RFID tags can be used to track and manage inventory of raw materials, components, and finished products in real-time, improving supply chain visibility and reducing manual tracking efforts.

- Asset Tracking: RFID technology helps in monitoring and tracking tools, equipment, and specialized components used in the manufacturing process, preventing loss and ensuring proper utilization.

- Production Line Automation: RFID tags attached to vehicles and components can automate the assembly process, ensuring the correct sequence and components are used, reducing errors and enhancing efficiency.

- Work-in-Progress Tracking: RFID tags enable real-time tracking of vehicles as they move through different stages of production, allowing manufacturers to monitor progress and identify bottlenecks.

- Quality Control: RFID systems can be integrated with quality control processes, ensuring that vehicles and components meet required standards at each stage of manufacturing.

- Maintenance and Repairs: RFID technology can be used to track maintenance schedules and repair history of vehicles, optimizing maintenance operations and prolonging vehicle lifespan.

- Traceability and Compliance: RFID tags provide a traceable record of components and materials used in vehicle manufacturing, aiding in regulatory compliance and recalls if necessary.

- Logistics and Distribution: RFID can streamline logistics by tracking vehicles as they move through distribution centers, helping in efficient loading, unloading, and delivery.

- Customization and Configuration: RFID tags can store information about a vehicle’s configuration and customization options, ensuring that the final product meets customer specifications.

- Security and Anti-Theft: RFID-based security systems can help protect vehicles and components from theft by triggering alerts if tagged items are moved without authorization.

- Supplier Management: RFID technology assists in managing relationships with suppliers by automating the tracking of incoming components and materials, improving efficiency in the supply chain.

- Energy Efficiency: RFID sensors can monitor energy usage in manufacturing processes, allowing for optimization and reducing energy consumption.

- Real-time Data Collection: RFID enables real-time data collection, which can be analyzed to identify patterns, inefficiencies, and areas for improvement in the manufacturing process.

- Employee Tracking and Safety: RFID badges worn by employees can help track their movements for safety purposes, ensuring that they are in designated areas and avoiding potential hazards.

- Warranty and Service History: RFID tags can store information about a vehicle’s warranty, service history, and maintenance requirements, helping with customer support and after-sales service.

- Lifecycle Management: RFID technology aids in tracking the entire lifecycle of a commercial vehicle, from manufacturing to disposal, for better management and environmental considerations.

- Regulatory Compliance: RFID can assist in ensuring that vehicles adhere to regulatory requirements by providing accurate data about their components, assembly, and testing processes.

- Data Analyticsb RFID-generated data can be analyzed to gain insights into production trends, quality issues, and overall operational efficiency.

- Remote Monitoring: RFID technology allows for remote monitoring of various aspects of the manufacturing process, improving oversight and troubleshooting capabilities.

- Just-in-Time Manufacturing: RFID systems facilitate just-in-time manufacturing by enabling accurate tracking and delivery of components to the production line as needed.

- Worker Authentication: RFID badges can be used to authenticate workers and grant them access to specific areas based on their roles and responsibilities.

- Process Optimization: RFID data can be used to identify bottlenecks and inefficiencies in the manufacturing process, enabling continuous improvement efforts.

- Predictive Maintenance: RFID-enabled sensors can help predict when maintenance is needed by monitoring the condition of components in real-time.

- Supplier Collaboration: RFID technology enhances collaboration with suppliers by providing real-time information about inventory levels, demand, and production status.

- Lean Manufacturing: RFID can support lean manufacturing principles by minimizing waste, reducing lead times, and optimizing resource utilization.

GAO’s drone technologies find the following applications in the Commercial Vehicle Manufacturing industry:

- Inventory Management: Drones can be used to conduct aerial surveys of inventory yards, providing accurate and up-to-date information on the quantity and location of vehicles and components.

- Site Inspection: Drones can inspect manufacturing facilities, identifying maintenance needs, safety hazards, and other issues that might be challenging to observe from ground level.

- Quality Control: Drones equipped with high-resolution cameras and sensors can inspect vehicles for defects and imperfections, ensuring adherence to quality standards.

- Supply Chain Monitoring: Drones can monitor the movement of materials and components within the supply chain, enhancing visibility and efficiency.

- Logistics Optimization: Drones can be employed to monitor and optimize the movement of vehicles within manufacturing facilities, improving the flow of production processes.

- Remote Surveillance: Drones enable remote real-time surveillance of production lines, ensuring smooth operations and identifying potential bottlenecks.

- Progress Tracking: Drones can capture aerial images and videos of vehicles in different stages of production, allowing for real-time monitoring of work-in-progress.

- Facility Mapping: Drones can create accurate 3D maps and models of manufacturing facilities, aiding in facility design, layout planning, and process optimization.

- Maintenance Inspections: Drones can inspect the exterior and hard-to-reach parts of vehicles for maintenance needs, improving safety and efficiency during maintenance operations.

- Safety Compliance: Drones can monitor adherence to safety protocols, identifying potential hazards and ensuring a safe working environment for employees.

- Prototype Testing: Drones can carry out prototype testing, collecting data on vehicle performance and aerodynamics for design improvements.

- Environmental Monitoring: Drones can monitor environmental conditions in and around manufacturing facilities, ensuring compliance with regulations and minimizing the environmental impact.

- Security Surveillance: Drones can provide security surveillance of manufacturing sites, helping to prevent unauthorized access and theft.

- Employee Training: Drones can be used in employee training programs, simulating real-world scenarios and safety procedures.

- Marketing and Promotion: Drones can capture impressive aerial footage of manufacturing facilities and finished vehicles for marketing and promotional materials.

- Emergency Response: Drones can assist in emergency response situations by quickly assessing damage and providing insights to responders.

- Virtual Tours: Drones can provide virtual tours of manufacturing facilities to clients, partners, and potential customers, offering a unique perspective.

- Data Collection for Analysis: Drones can gather data on various aspects of manufacturing operations, which can be analyzed for process improvement and efficiency optimization.

- Aerial Inspections: Drones can inspect roofs, structures, and large equipment within manufacturing sites, identifying maintenance needs and potential issues.

- Customization and Personalization: Drones can capture images and measurements for vehicle customization and personalization, allowing customers to visualize their choices.

- Regulatory Compliance: Drones can help ensure compliance with regulatory standards by providing accurate data on manufacturing processes.

- Research and Development: Drones can aid in research and development efforts by collecting data on vehicle performance, materials, and processes.

- Waste Management: Drones can monitor waste disposal areas and assess waste management practices for sustainability and compliance.

- Collaboration and Communication: Drones can facilitate communication by providing visual updates to stakeholders, suppliers, and clients.

- Real Estate Management: Drones can assist in managing manufacturing site properties, tracking changes and developments over time.

- Training Simulations: Drones can simulate scenarios for training employees on emergency response, safety procedures, and equipment operation.

GAO’s IoT technologies, consisting of IoT sensors, sensors networks and systems, find the following applications in the Commercial Vehicle Manufacturing industry:

- Predictive Maintenance: IoT sensors can monitor the condition of vehicle components in real-time, predicting maintenance needs and reducing downtime.

- Remote Diagnostics: IoT-enabled devices can diagnose vehicle issues remotely, allowing manufacturers to troubleshoot and provide solutions without physical presence.

- Supply Chain Optimization: IoT can track the movement of components and materials through the supply chain, enhancing visibility and efficiency.

- Inventory Management: IoT sensors can monitor inventory levels and automatically trigger reordering of parts and components.

- Real-time Production Monitoring: IoT devices can monitor the production line in real-time, providing insights into efficiency, bottlenecks, and process improvements.

- Quality Assurance: IoT sensors can track and analyze data during manufacturing to ensure vehicles meet quality standards.

- Energy Efficiency: IoT can monitor energy consumption in manufacturing facilities, helping to identify energy-saving opportunities.

- Remote Software Updates: IoT enables over-the-air software updates for vehicles, improving functionality and fixing issues without requiring physical visits.

- Vehicle Tracking: IoT-based tracking systems can monitor the location and movement of vehicles within manufacturing facilities.

- Worker Safety: IoT sensors can monitor worker activities and conditions, enhancing safety protocols and ensuring compliance.

- Customization and Configuration: IoT can facilitate real-time customization of vehicle features and configurations based on customer preferences.

- Asset Tracking: IoT devices can track tools, equipment, and assets used in the manufacturing process to prevent loss and optimize utilization.

- Data Analytics: IoT-generated data can be analyzed to identify trends, patterns, and areas for improvement in the manufacturing process.

- Smart Manufacturing: IoT can create a connected ecosystem where machines, processes, and people interact intelligently, leading to streamlined operations.

- Waste Reduction: IoT sensors can monitor waste production and disposal, helping to reduce waste and improve sustainability.

- Collaborative Robotics: IoT can enable collaborative robots (cobots) to work alongside human workers, enhancing efficiency and safety.

- Supply Chain Visibility: IoT can provide end-to-end visibility into the supply chain, helping manufacturers anticipate disruptions and optimize logistics.

- Remote Monitoring and Control: IoT allows remote monitoring and control of manufacturing equipment and processes, improving operational efficiency.

- Real-time Alerts: IoT devices can send real-time alerts about equipment malfunctions, allowing for prompt maintenance and reducing downtime.

- Data-driven Decision Making: IoT-generated data can inform decision-making processes, leading to better-informed strategies and improvements.

- Regulatory Compliance: IoT can help ensure compliance with industry regulations by capturing data on manufacturing processes and vehicle components.

- Augmented Reality (AR) Assistance: IoT devices can work in conjunction with AR systems to provide visual guidance and assistance to workers during complex tasks.

- Smart Tooling: IoT-enabled tools can provide data on their usage, helping to optimize their performance and maintenance.

- Enhanced Customer Experience: IoT devices can offer customers insights into the manufacturing process, allowing them to track their vehicle’s progress.

- Simulation and Testing: IoT-generated data can be used for virtual simulations and testing, reducing the need for physical prototypes.

- Optimized Production Scheduling: IoT data can help optimize production scheduling by identifying bottlenecks and adjusting workflows.

- Lifecycle Tracking: IoT enables tracking of vehicles from manufacturing through usage, maintenance, and end-of-life considerations.

- Process Automation: IoT can automate processes such as material handling, assembly, and quality control, improving efficiency and reducing errors.

GAO’s Assists Clients with Standards, Mandates & Regulations of Commercial Vehicle Manufacturing Industry

GAO RFID Inc. has developed its products and systems in compliance with industry standards and mandates. GAO has assisted our customers in Commercial Vehicle Manufacturing industry to deploy RFID, BLE, IoT and drone systems and to ensure such deployments complying with applicable industry standards, U.S. government regulations and Canadian government regulations such as:

RFID, BLE, IoT, & Drone Standards & Mandates

- ISO 18000-6C

- ISO 14443

- ISO 15693

- EPC Gen2

- ISO 14223

- ISO 18000-7

- Bluetooth 4.0 (Bluetooth Low Energy)

- Bluetooth 4.1

- Bluetooth 4.2

- Bluetooth 5.0

- Bluetooth 5.1

- Bluetooth 5.2

- MQTT (Message Queuing Telemetry Transport)

- CoAP (Constrained Application Protocol)

- HTTP/HTTPS (Hypertext Transfer Protocol/Secure)

- AMQP (Advanced Message Queuing Protocol)

- OPC UA (Open Platform Communications Unified Architecture)

- Zigbee

- Z-Wave

- LoRaWAN

- Thread

- 6LoWPAN (IPv6 over Low Power Wireless Personal Area Networks)

- ASTM F38

- ISO 21384

- FAA Part 107 (United States)

- JARUS (Joint Authorities for Rulemaking on Unmanned Systems)

- EASA (European Union Aviation Safety Agency) regulations

- ICAO (International Civil Aviation Organization) regulations

- EPC Gen2 for RFID tagging in automotive supply chains

- ISO 18000-6C for UHF RFID applications

- ISO 14223 for RFID-based tire identification

- BLE usage for asset tracking in manufacturing facilities

- BLE-based vehicle diagnostics and maintenance tracking

- Integration of IoT devices for real-time vehicle tracking

- IoT-enabled predictive maintenance solutions for commercial vehicles

- Regulatory compliance with national aviation authorities for drone usage in manufacturing

- Adherence to industry-specific safety guidelines for drone operations in manufacturing environments

US. Government Regulations

- Federal Motor Carrier Safety Regulations (FMCSRs)

- National Highway Traffic Safety Administration (NHTSA) Regulations

- Environmental Protection Agency (EPA) Emission Standards

- Occupational Safety and Health Administration (OSHA) Guidelines

- Federal Vehicle Safety Standards (FMVSS)

- Department of Transportation (DOT) Regulations

- Clean Air Act Regulations

- Commercial Vehicle Hours of Service Regulations

- Federal Aviation Administration (FAA) Regulations for Commercial Drones

- National Transportation Safety Board (NTSB) Regulations

Canadian Government Regulations

- Motor Vehicle Safety Regulations (MVSR)

- Transport Canada Regulations

- Canadian Environmental Protection Act (CEPA) Regulations

- Canada Motor Vehicle Safety Standards (CMVSS)

- Canadian Aviation Regulations (CARs) for Commercial Drones

- Occupational Health and Safety Regulations

- Canadian Standards Association (CSA) Guidelines for Commercial Vehicles

- Provincial and Territorial Regulations for Commercial Vehicles

- Canadian Transportation of Dangerous Goods (TDG) Regulations

- Canadian National Energy Board (NEB) Regulations for Transportation

- Transport Dangerous Goods (TDG) Regulations

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions, and offers an API to the important systems in Commercial Vehicle Manufacturing industry such as:

Personnel Management:

- Employee Scheduling and Shift Management

- Training and Certification Tracking

- Performance Evaluation and Appraisals

- Health and Safety Compliance

- Payroll and Benefits Administration

- Workforce Analytics and Reporting

Equipment Management:

- Preventive Maintenance Scheduling

- Equipment Tracking and Utilization

- Repairs and Service History Management

- Asset Lifecycle Management

- Equipment Calibration and Inspection Tracking

Access Control:

- Secure Entry and Exit Management

- Visitor Management and Badging

- Identity Verification and Authentication

- Access Logs and Audit Trails

- Security Incident Monitoring

Warehouse Management:

- Inventory Tracking and Management

- Order Fulfillment and Picking Optimization

- Stock Rotation and Shelf-Life Management

- Warehouse Layout and Space Utilization

- Real-time Location Systems (RTLS) for Asset Tracking

Supply Chain Management:

- Supplier Relationship Management

- Demand Forecasting and Planning

- Procurement and Purchase Order Management

- Supplier Quality Management

- Vendor Collaboration and Communication

Other Applications:

- Production Line Monitoring and Automation

- Quality Control and Defect Detection

- Regulatory Compliance Tracking

- Environmental Sustainability Monitoring

- Telematics and Fleet Management

- Warranty and Recall Management

- Customer Order Tracking and Management

GAO has enabled its customers to make use of some of the leading software and cloud services in Commercial Vehicle Manufacturing industry. Below are some of popular software and cloud services in Commercial Vehicle Manufacturing industry.

SAP SuccessFactors, Workday Human Capital Management, Oracle HCM Cloud, ADP Workforce Now, Bamboo HR, Microsoft Azure, Amazon Web Services (AWS), Google Cloud Platform (GCP), IBM Cloud, Salesforce, IBM Maximo, Infor EAM, Fix, Up Keep, Maintenance Connection, Microsoft Azure IoT, AWS IoT Core, Google Cloud IoT, IBM Watson IoT, Oracle Internet of Things (IoT) Cloud Service, HID Global, LenelS2, Genetec, Avigilon Control Center, Brivo, Manhattan Associates WMS, SAP Extended Warehouse Management (EWM), JDA Warehouse Management, High Jump Warehouse Management System, Infor Supply Chain Execution, Microsoft Azure Logistics and Transportation, Oracle Cloud SCM, IBM Sterling Supply Chain Business Network, SAP Integrated Business Planning for Supply Chain, Kinaxis Rapid Response, SAP Integrated Business Planning, Oracle SCM Cloud, JDA Supply Chain Management, Kinaxis Rapid Response, Blue Yonder (formerly JDA Software),AWS Supply Chain Solutions, Google Cloud Supply Chain Solutions, Microsoft Azure Supply Chain Solutions, IBM Sterling Supply Chain Suite, Oracle Cloud SCM, Siemens Teamcenter, Dassault System DELMIA, PTC Windchill, Auto Desk Fusion Lifecycle, SAP PLM.

GAO has worked with some of the leading technology companies in Commercial Vehicle Manufacturing industry to provide integrated RFID, BLE, IoT and drone solutions to customers. Here are some of the technology leaders in Commercial Vehicle Manufacturing industry:

SAP, Oracle, Microsoft, IBM, Salesforce, Bosch, Continental, Aptiv, Denso, Magna International, Siemens, Schneider Electric, Rockwell Automation, ABB, Honeywell.

Case Studies of RFID, IoT & Drone Applications

Case Studies of RFID Applications

Below are some RFID application cases Commercial Vehicle Manufacturing industry:

Inventory Management, Work-in-Progress Tracking, Quality Control, Asset Tracking, Production Line Automation, Traceability, Maintenance Tracking, Supply Chain Visibility, Customization and Configuration, Security, Automated Component Identification, Real-time Work-in-Progress Tracking, Error Prevention and Quality Control, Efficient Inventory Management, Supply Chain Visibility, Customization and Configuration Tracking, Maintenance Scheduling, Access Control and Security, Traceability and Compliance, Workplace Safety, Assembly Line Optimization, Maintenance and Service History, Data Analytics and Process Optimization, Smart Inventory Management, Automated Assembly Line, Predictive Maintenance, Security Enhancement, Efficient Workflows, Data Analytics and Insights.

Many applications of RFID by GAO can be found here:

RFID and BLE for Automation and Control System Manufacturing (gaorfid.com)

Case Studies of IoT Applications

Below are some IoT application cases in Commercial Vehicle Manufacturing industry

Remote Vehicle Monitoring and Predictive Maintenance, Connected Supply Chain Optimization, Predictive Quality Control Enhancements, Smart Assembly Line Integration, Real-time Tracking for Efficient Production, Fleet Management and Optimization, Energy Efficiency through IoT Sensors, Customization and Personalization Solutions, Remote Diagnostics and Troubleshooting, Data Analytics for Operational Insights, Smart Factory Integration for Enhanced Production, Real-time Asset Tracking and Management, Supply Chain Visibility and Traceability Solutions, Predictive Maintenance Optimization, Real-time Quality Control and Compliance Monitoring, Energy Management for Manufacturing Efficiency, Worker Safety and Productivity Enhancement, Efficient Fleet Management Solutions, Data-driven Decision Making through IoT Analytics, Remote Monitoring and Control of Manufacturing Processes, IoT-enabled Smart Factories for Streamlined Production, Real-time Asset Tracking and Inventory Management, Supply Chain Visibility and Optimization, Predictive Maintenance and Downtime Reduction, Quality Control Enhancement through Real-time IoT Insights, Energy Efficiency and Sustainability Solutions, Worker Safety and Productivity Boost with IoT Integration, Fleet Management and Logistics Optimization, Data Analytics for Informed Decision Making, Remote Monitoring and Control of Manufacturing Operations.

Case Studies of Drone Applications

Below are some drone application cases in Commercial Vehicle Manufacturing industry:

Drone-assisted Inventory Management and Warehousing ,Automated Inspection of Manufacturing Facilities with Drones, Drones for Monitoring and Maintenance of Large Manufacturing Equipment ,Remote Aerial Surveillance for Enhanced Security, Drone-enabled Quality Control and Defect Detection, Drones for Site Surveys and Facility Planning, Efficient Material Delivery using Drone Logistics, Aerial Data Collection for Production Line Efficiency, Drones for Safety Inspections and Hazard Detection, Precision Aerial Measurements for Manufacturing Processes, Utilizing Drones for Facility Inspection and Maintenance, Aerial Surveillance and Security Enhancement in Manufacturing, Drone-assisted Quality Control and Defect Detection, Efficient Inventory Management through Aerial Scanning, Aerial Mapping and Site Planning for Manufacturing Facilities, Drones for Logistics and Material Handling Optimization, Precision Measurements and Monitoring with Aerial Drones, Enhancing Workplace Safety through Aerial Inspections ,Remote Monitoring of Manufacturing Processes via Drones, Aerial Data Collection for Operational Efficiency, Drone-assisted Facility Inspection and Maintenance, Aerial Surveillance for Manufacturing Security, Quality Control and Defect Detection using Aerial Drones, inventory Management Optimization using Aerial Scans, Aerial Mapping and Site Planning for Manufacturing Facilities ,Drones for Logistics and Material Transport Efficiency, Precision Measurements and Monitoring via Aerial Drones, Workplace Safety Enhancement through Aerial Inspections, Remote Monitoring of Manufacturing Processes with Drones, Aerial Data Collection for Operational Insights, Drone-assisted Facility Inspection and Maintenance in Manufacturing, Aerial Surveillance for Enhanced Security in Manufacturing Facilities, Quality Control and Defect Detection using Aerial Drones, Aerial Scanning for Efficient Inventory Management, Aerial Mapping and Site Planning for Manufacturing Sites, Drones for Logistics and Material Handling Optimization, Precision Measurements and Monitoring with Aerial Drones, Aerial Inspections for Workplace Safety Enhancement, Remote Monitoring of Manufacturing Processes via Drones, Aerial Data Collection for Data-driven Operational Efficiency.

GAO RFID Systems & Hardware for Commercial Vehicle Manufacturing Industry

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antenna, printers, and integrated RFID systems for various industries, including Commercial Vehicle Manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including Commercial Vehicle Manufacturing industry

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including Commercial Vehicle Manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including Commercial Vehicle Manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including Commercial Vehicle Manufacturing industry:

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including Commercial Vehicle Manufacturing industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 13.56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

In collaboration with its sister company GAO Tek Inc, a wide selection of high-quality drones are offered:

The RFID systems by GAO are highly popular for clients in Commercial Vehicle Manufacturing industry

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

Computer-Aided Design (CAD) Software, Computer-Aided Manufacturing (CAM) Software, Robotics and Automation Equipment, CNC Machines, Welding Equipment, Painting Booths and Equipment, Assembly Line Equipment, Testing and Inspection Equipment, Diagnostic Tools, Material Handling Equipment, Sheet Metal Forming Equipment, Hydraulic Presses, Chassis Dynamometers, Ergonomic Tools, 3D Printing and Additive Manufacturing Equipment, Emission Testing Equipment, Electrical Testing Equipment, Alignment and Suspension Testing Equipment, Noise and Vibration Testing Equipment, Crash Test Equipment, Telematics and Fleet Management Systems, Lifting and Hoisting Equipment, Maintenance and Repair Tools, Safety Gear and Personal Protective Equipment (PPE), Supply Chain Management Software.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

Furthermore, GAO provides the customization of RFID tags, RFID readers, BLE beacons and BLE gateways, IoT, drones, and systems and consulting services for Commercial Vehicle Manufacturing industry and for various industries in all metropolitans in North America, particularly the U.S., Canada and Mexico, and Europe:

GAO Makes Efforts to Satisfy Customers

Large Choice of Products

In order to satisfy the diversified needs of their corporate customers, GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drones, testing and measurement devices, and network products.

Overnight Delivery

In order to shorten the delivery to our customers, GAO has maintained a large stock of its products and is able to ship overnight within continental U.S. and Canada, and fast delivery to anywhere in Mexico and Europe from the nearest warehouse.

Local to Our Customers

We are located in both the U.S. and Canada. We travel to customers’ premises if necessary. Hence, we provide a very strong local support to our customers in North America, particularly the U.S., Canada and Mexico, and Europe. Furthermore, we have built partnerships with some integrators, consulting firms and other service providers in different cities to further strengthen our services. Here are some of the service providers in Commercial Vehicle Manufacturing industry we have worked with to serve our joint customers:

- Accenture

- Deloitte

- Cognizant

- Capgemini

- Infosys

- IBM Global Business Services

- Wipro

- Tech Mahindra

- Tata Consultancy Services (TCS)

- HCL Technologies

- PwC (PricewaterhouseCoopers)

- KPMG

- EY (Ernst & Young)

- CGI

- Atos

- NTT DATA

- Hexaware Technologies

- BearingPoint

- Sopra Steria

- Sogeti

GAO Has Served Commercial Vehicle Manufacturing Industry Extensively

GAO RFID Inc. and its sister company GAO Tek Inc. together offer a wide choice of RFID, BLE, IoT, drone, testing and measurement devices, and network products.

GAO’s products and technologies have helped its customers in Commercial Vehicle Manufacturing industry to achieve success in

Electric Mobility, Autonomous Vehicles, Connected Vehicles, Industry 4.0, Predictive Maintenance, Digital Twin, Additive Manufacturing, Sustainable Manufacturing, Big Data, Supply Chain Visibility, Blockchain, Drones and Robotics, Driver Assistance Systems, Lightweighting, Telematics, V2X Communication, Smart Manufacturing, Cybersecurity, Circular Economy, Urbanization and Last-Mile Delivery, Customer-Centric Solutions, Hydrogen Fuel Cells, E-Mobility Infrastructure, Data Monetization, Green Manufacturing.

GAO RFID Inc. has served many customers in Spring and Wire Product Manufacturing, including its various divisions such as:

- Heavy-Duty Trucks: Manufacturing of large trucks used for transporting goods, construction, and other heavy-duty applications.

- Light-Duty Trucks: Production of smaller trucks, vans, and pickups used for various purposes including transportation, delivery, and trades.

- Buses and Coaches: Manufacturing of various types of buses and coaches for public transportation, tourism, and commercial purposes.

- Special Purpose Vehicles: Production of vehicles designed for specific industries or tasks, such as emergency vehicles, utility vehicles, and specialized construction vehicles.

- Trailer and Body Manufacturing: Manufacturing of trailers, bodies, and container units that are attached to trucks for transporting goods.

- Electric and Hybrid Vehicles: Design and production of electric and hybrid commercial vehicles to address sustainability and emissions concerns.

- Automated and Autonomous Vehicles: Development of self-driving and automated vehicles for applications such as logistics, warehousing, and delivery.

- Component Manufacturing: Production of various components such as engines, transmissions, axles, and chassis used in commercial vehicles.

- Telematics and Fleet Management: Providing technology solutions for vehicle tracking, monitoring, and fleet management services.

- Supply Chain Management: Focus on optimizing the supply chain and logistics processes involved in producing and delivering commercial vehicles.

- Aftermarket and Service: Providing maintenance, repair, and spare parts for commercial vehicles throughout their lifecycle.

- Fleet Solutions: Offering comprehensive fleet management services, including vehicle leasing, financing, and optimization.

- Vehicle Customization and Upfitting: Customizing commercial vehicles based on specific industry needs, such as adding specialized equipment or storage solutions.

- Alternative Fuel Vehicles: Development and production of commercial vehicles powered by alternative fuels like natural gas, hydrogen, and biofuels.

- Vehicle Safety and Technology: Research and implementation of safety features, driver assistance systems, and technology solutions to enhance vehicle efficiency and safety.

- Logistics and Distribution: Managing the distribution of commercial vehicles to dealerships, customers, and rental companies.

- Regulatory Compliance and Standards: Ensuring vehicles comply with regulatory standards and emissions regulations in different regions.

- Research and Development: Engaging in research and development activities to innovate and improve commercial vehicle technologies and designs.

- Global Operations: Managing international operations, production facilities, and partnerships to serve global markets.

- Vehicle Recycling and Sustainability: Focusing on eco-friendly vehicle designs, materials, and end-of-life recycling practices.

GAO’s technologies enable its customers in “Commercial Vehicle Manufacturing industry” to effectively track their workforces such as Assembler, Welder, Fabricator, Painter, Mechanic, Technician, Engineer, Designer, Quality Control Inspector, Electrician, Assembler Line Operator, Driver, Supervisor, Machinist, Maintenance Technician, Logistics Coordinator, Materials Handler, Production Manager, Safety Officer, Tester/Quality Analyst, CNC Operator, Prototype Builder, Tool and Die Maker, Upholsterer, Maintenance Supervisor track operational assets such as CNC Machines, Presses, Welding Robots, Paint Booths, Assembly Lines, Hydraulic Presses, Laser Cutting Machines, Robotic Arm Systems, Material Handling Systems, Inspection and Testing Equipment, Automated Guided Vehicles (AGVs), Injection Molding Machines, Powder Coating Equipment, Welding Fixtures, Plasma Cutting Machines, Riveting Machines, CNC Plasma Cutters, Tube Bending Machines, Soldering Stations.

Here are some of the leading companies in Commercial Vehicle Manufacturing industry GAO has served:

- Mack Trucks

- Thomas Built Buses

- Navistar International

- Freightliner Trucks (part of Daimler Trucks North America)

- Hino Motors Manufacturing (part of Toyota Group)

- Ford Motor Company

- General Motors

- Oshkosh Corporation

- PACCAR (Kenworth and Peterbilt divisions)

- Tesla, Inc.

- Spartan Motors

- Lyons motor car

- Meyers manx

- Mullen technologies

- Next Autoworks

- Myers motors

- N2A motors

- Niama Reisser

- Nikola corporation

- Palatoy motorsport

- Panoz

- Polaris

- Raeser

- Ronn motor group

- Nova Bus

- Prevost

- Lion Electric

- MANAC

- Arboc Mobility

- Trans Tech Bus

You Are Invited to Contact Us!

If you are interested in our products, services or partnering with us, please feel free to contact us by filling out this form:

or email us at sales@gaorfid.com