Index for Contents on This Page:

Applications & Benefits of GAO’s RFID, BLE, IoT & Drones for the Hardware Manufacturing Industry

GAO Software Provides Easy Integration with API

Case Studies of RFID Applications

GAO RFID Systems & Hardware for the Hardware Manufacturing Industry

GAO Has Served the Hardware Manufacturing Industry Extensively

Related Products & Systems on Other Pages on This Website

Electronic Instrument Manufacturing Industry – GAO RFID

Pallet & Return Asset Tracking System

People Tracking System for Manufacturing Facilities

Work In Process WIP Asset Tracking System

BLE | Bluetooth Low Energy | BLE Gateways & Beacons – GAO RFID

RFID Readers | Buy RFID Readers | RFID Reader Writers – GAO RFID

RFID Tags | Buy RFID Tags – GAO RFID

Tamper Proof RFID Tags | Security RFID Tags – GAO RFID

On Metal RFID Tags – All Types

Overview

The hardware manufacturing industry is responsible for designing, developing, and producing physical products such as computers, smartphones, automobiles, medical devices, and other electronic equipment. This industry encompasses a wide range of businesses, including small startups and large multinational corporations. The industry is constantly evolving due to advancements in technology, changes in consumer demands, and global competition, which has led to the development of innovative products and improved manufacturing processes.

GAO’s RFID, BLE, IoT, and drone technologies have helped its customers in the hardware manufacturing industry to improve their work processes, operations, and productivity by better managing their staff, materials, and operational equipment such as CNC machines, Injection molding machines, Presses (mechanical, hydraulic, or pneumatic), Lathes, Drilling machines, Cutting machines, Welding machines (e.g. TIG, MIG, ARC), Surface treatment equipment (e.g. sandblasting, electroplating), Soldering and desoldering stations, Test and measurement equipment (e.g. oscilloscopes, multimeters), Assembly line equipment (e.g. conveyors, robots, pick-and-place machines), Computer-aided design (CAD) software and hardware, 3D printers, Packaging and labeling machines, and Material handling equipment (e.g. forklifts, cranes).

Ranked as one of the top 10 global RFID suppliers, GAO RFID Inc. is based in New York City, U.S., and Toronto, Canada. GAO offers a comprehensive selection of UHF, HF (including NFC), and LF RFID (radio frequency identification) readers and tags, BLE (Low Energy Bluetooth) gateways and beacons, and various RFID and BLE systems such as people tracking, asset tracking, access control, parking control, fleet management, WIP (work in progress), traceability. Such RFID and BLE products and systems and their IoT and drone technologies have been successfully deployed in the hardware manufacturing industry.

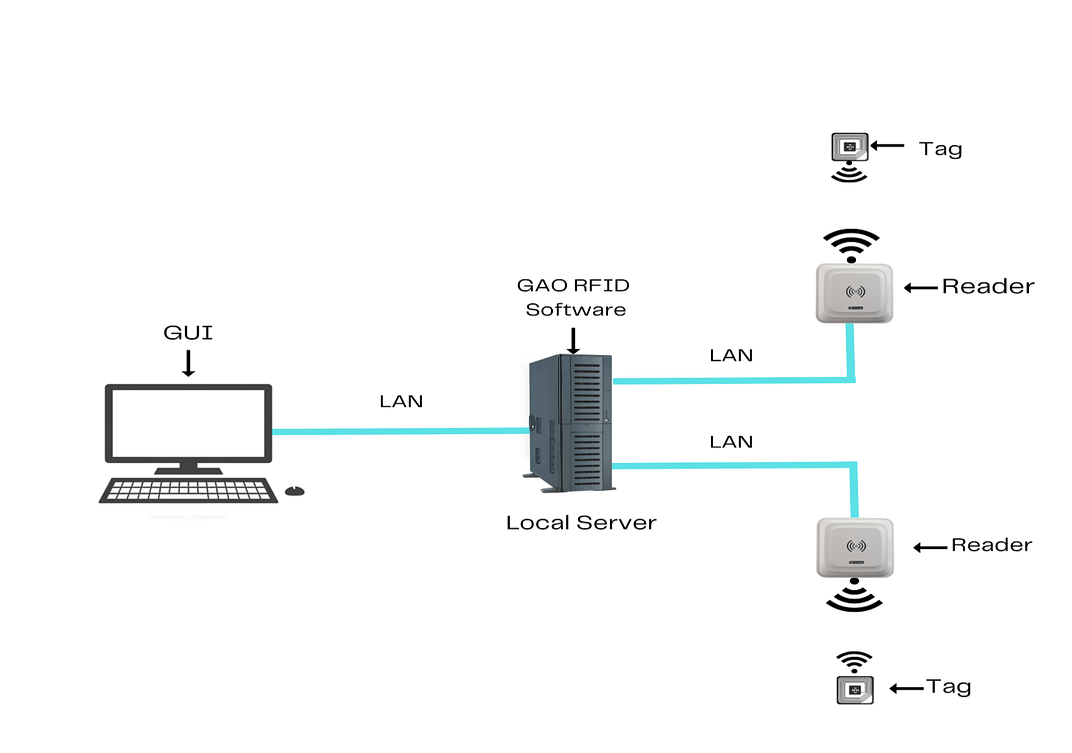

GAO’s RFID or RFID Systems for the hardware manufacturing industry are offered in 2 versions to satisfy its customers. One version is that its software runs on a local server, and another is that it runs in the cloud. The above illustrates the GAO system for the hardware manufacturing industry with its software running on a local server.

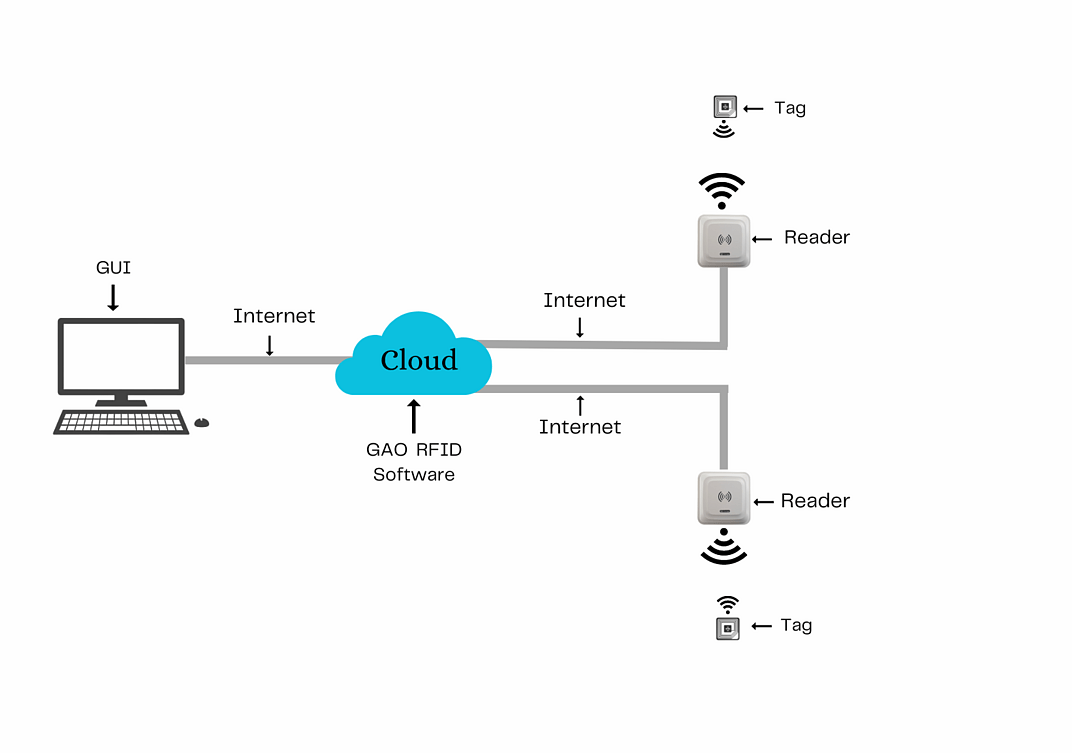

The above illustrates the GAO system for the hardware manufacturing industry with its software running in the cloud

GAO’s RFID technologies bring many benefits to the hardware manufacturing industry:

- Improved Inventory Management: Our RFID technology can enable real-time visibility of inventory, reducing the risk of stock-outs or overstocking. This can lead to improved efficiency and cost savings.

- Enhanced Quality Control: GAO’s RFID tags can be used to track components throughout the manufacturing process, enabling better quality control and reducing the risk of defects or errors.

- Increased Productivity: Our company’s RFID technology can automate many tasks, such as tracking the movement of components and monitoring the status of machines. This can lead to increased productivity and reduced downtime.

- Enhanced Supply Chain Management: GAO’s RFID technology can provide real-time visibility into the supply chain, enabling better coordination and collaboration among suppliers, manufacturers, and distributors.

- Improved Asset Management: GAO’s RFID technology can be used to track the location and status of equipment and tools, reducing the risk of loss or theft and improving asset utilization.

GAO’s BLE technologies offer a longer reading range and are particularly attractive for applications with larger workspaces within the hardware manufacturing industry:

- Asset Tracking: Our company’s BLE (Bluetooth Low Energy) technology can be used to track assets, such as tools and equipment, in real time. This can improve visibility and reduce the risk of loss or theft.

- Condition Monitoring: GAO’sBLE sensors can be attached to machines and equipment to monitor their condition in real-time. This can enable predictive maintenance, reducing downtime and repair costs.

- Indoor Positioning: OurBLE beacons can be used to enable indoor positioning, allowing manufacturers to track the movement of workers and assets in real-time. This can improve efficiency and safety.

- Worker Safety: GAO’s BLE wearables can be used to monitor the health and safety of workers, such as tracking their movements and detecting hazardous conditions. This can improve workplace safety and reduce the risk of accidents.

GAO’s RFID and drone technologies are often combined and such solutions offer the following benefits to the hardware manufacturing industry:

- Automated Inventory Management: GAO’s RFID technology can be used to track inventory, while drones can be used to perform physical inventory checks. This can automate the inventory management process and reduce the risk of errors.

- Efficient Asset Tracking: Our RFID tags can track the location of assets, while drones can quickly locate and retrieve them. This can improve asset utilization and reduce the risk of loss or theft.

- Remote Inspection: Drones can be equipped with GAO’s RFID readers to perform remote inspections of assets and equipment. This can reduce the need for manual inspections, saving time and improving safety.

- Improved Supply Chain Visibility: Our RFID tags can be used to track products throughout the supply chain, while drones can monitor shipments’ status in real time. This can improve supply chain visibility and enable better coordination among suppliers, manufacturers, and distributors.

Here are the benefits of GAO’s IoT technologies to the hardware manufacturing industry:

- Predictive Maintenance: IoT sensors can monitor machines and equipment in real-time, detecting potential issues before they become major problems. This can enable predictive maintenance, reducing downtime and repair costs.

- Improved Energy Efficiency: IoT sensors can monitor energy usage in the manufacturing process, identifying areas for improvement and enabling more efficient energy usage. This can lead to cost savings and reduced environmental impact.

- Enhanced Worker Safety: IoT wearables can be used to monitor the health and safety of workers, such as tracking their movements and detecting hazardous conditions. This can improve workplace safety and reduce the risk of accidents.

- Real-time Analytics: IoT devices can generate vast amounts of data about the manufacturing process, which can be used to identify inefficiencies and improve performance in real time. This can lead to improved productivity and cost savings.

GAO Helps Customers Comply with Standards, Mandates & Regulations of the Hardware Manufacturing

GAO RFID Inc. has helped many companies in the hardware manufacturing industry to deploy RFID, BLE, IoT, and drone systems and to ensure such deployments comply with the applicable industry standards, mandates, and government regulations:

RFID, BLE, IoT, & Drone Standards & Mandates

- International Organization for Standardization (ISO) 18000: This standard specifies the requirements for RFID technology used in supply chain management, including the hardware and software required for RFID systems.

- International Organization for Standardization(ISO) 15693: This standard specifies the technical requirements for RFID technology used for item identification in manufacturing and other industries.

- Institute of Electrical and Electronics Engineers(IEEE) 802.15.4: This standard defines the physical and media access control (MAC) layer for low-rate wireless personal area networks (WPANs), including BLE.

- Bluetooth SIG: The Bluetooth Special Interest Group is responsible for developing and promoting the Bluetooth standard, including the development of new profiles and specifications.

- Zigbee Alliance: The Zigbee Alliance is a group of companies that develop and promote the Zigbee wireless communication standard for IoT devices.

- Wi-Fi Alliance: The Wi-Fi Alliance is responsible for certifying and promoting Wi-Fi technology, including standards for IoT devices.

- Advanced Technology Attachment(ATA) Spec 2000: A standard for RFID technology used in the aerospace industry, including specifications for data formatting and tag placement.

- International Civil Aviation Organization (ICAO): The International Civil Aviation Organization sets global standards and regulations for the safe operation of aircraft, including drones.

- Occupational Safety and Health Administration(OSHA): The Occupational Safety and Health Administration sets workplace safety standards, including guidelines for the safe use of RFID, BLE, IoT, and drone technology in the manufacturing industry.

US. Government Regulations Related

- Department of Defense (DoD) RFID mandate: This mandate requires certain suppliers to use RFID technology to track shipments to the US Department of Defense.

- Environmental Protection Agency (EPA): The EPA regulates the use and disposal of hazardous materials in the manufacturing process, including the handling of electronic waste.

- National Institute of Standards and Technology (NIST): NIST is a government agency that develops and promotes standards for technology and manufacturing processes, including guidelines for cybersecurity in the manufacturing industry.

Canada Government Regulations

- Canadian Centre for Occupational Health and Safety (CCOHS): CCOHS sets workplace safety standards, including guidelines for the safe use of equipment and machinery in the manufacturing industry.

- Canadian National Railway (CN) RFID mandate: This mandate requires the use of RFID technology for tracking railcars and other assets on the Canadian National Railway network.

- Canadian Standards Association (CSA): CSA is a non-profit organization that develops and promotes standards for technology and manufacturing processes, including guidelines for cybersecurity in the manufacturing industry.

GAO Software Provides Easy Integration with API

GAO’s RFID and BLE software offers a free trial for both the server-based and cloud versions and offers an API to the important systems in the hardware manufacturing industry such as:

Personnel Management:

- Employee tracking and monitoring

- Time and attendance management

- Safety training and compliance management

- Performance management and evaluation

- Payroll management

Equipment Management:

- Preventive maintenance scheduling

- Equipment utilization tracking

- Equipment repair and maintenance tracking

- Asset tracking and management

- Equipment downtime management

Access Control:

- Access control and security monitoring

- Visitor management and tracking

- Identity verification and authentication

- Physical access control management

- Incident and emergency response management

Warehouse Management:

- Inventory tracking and management

- Stock level monitoring and control

- Receiving and shipping management

- Pick and pack management

- Quality control management

Supply Chain Management:

- Demand forecasting and planning

- Order management and fulfillment

- Supplier management and tracking

- Production scheduling and management

- Logistics and transportation management

Other Applications:

- Quality control and inspection management

- Compliance management and reporting

- Energy management and efficiency tracking

- Sustainability and environmental management

- Data analytics and reporting

GAO has integrated its RFID, BLE, IoT, and drone systems with some of the leading software and cloud services in the hardware manufacturing industry. Below are some of the popular software and cloud services in the hardware manufacturing industry.

- Systems, Applications & Products in Data Processing (SAP) SuccessFactors: A cloud-based human resource management system that helps businesses manage their workforce and employee data.

- Siemens Teamcenter: A product lifecycle management (PLM) software solution that helps businesses manage their product development processes from ideation to retirement.

- Oracle HCM Cloud: A cloud-based human resource management system that helps businesses manage their workforce, talent, and HR processes.

- Workday HCM: A cloud-based human resource management system that helps businesses manage their workforce, talent, and payroll processes.

- Kinaxis RapidResponse: A supply chain planning and response software that helps businesses manage their supply chain operations in real-time.

- Honeywell Pro-Watch: An access control and security management system that helps businesses control access to their facilities and monitor security events.

- Lenel OnGuarD: A security management system that provides access control, video surveillance, and alarm monitoring capabilities.

- Manhattan Associates Warehouse Management System: A software solution designed to help businesses manage their warehouse operations, including inventory, orders, and logistics.

- Autodesk Fusion 360: A cloud-based 3D modeling and design software that helps businesses create and prototype their products.

- Infor Supply Chain Management: A software solution designed to help businesses manage their supply chain operations, including procurement, inventory, and logistics.

- Blue Yonder Warehouse Management Cloud: A cloud-based software solution that helps businesses manage their warehouse operations. It provides capabilities for inventory management, order fulfillment, receiving, shipping, and putting away.

- Plex Systems: A cloud-based manufacturing software that helps businesses manage their production processes, quality control, and supply chain operations.

GAO has worked with some of the leading technology companies in hardware manufacturing to provide integrated RFID, BLE, IoT, and drone solutions to customers. Here are some of the technology leaders in the hardware manufacturing industry:

- Rockwell Automation: A leading provider of industrial automation and digital transformation solutions for the manufacturing industry.

- Honeywell International: A multinational conglomerate that produces a variety of commercial and consumer products, including aerospace systems, building technologies, and performance materials.

- Cisco Systems:A multinational technology conglomerate that provides networking, cybersecurity, and communication technology solutions.

- Accenture: A global professional services company that provides consulting, technology, and outsourcing services to businesses across various industries.

- International Business Machines (IBM): A multinational technology company that offers a wide range of hardware, software, and consulting services for businesses across various industries.

- Microsoft: A multinational technology company that provides software, hardware, and cloud-based solutions for businesses and consumers.

- Oracle: A multinational technology company that offers a wide range of hardware, software, and cloud-based solutions for businesses across various industries.

- Systems, Applications & Products in Data Processing (SAP):A multinational software corporation that provides enterprise software solutions for businesses across various industries.

- Qualcomm: A multinational semiconductor and telecommunications equipment company that designs and markets wireless telecommunications products and services.

- Texas Instruments:A multinational semiconductor and computer hardware company that designs and manufactures electronic components, including analog and embedded processors.

- Dell Technologies:A multinational technology company that provides hardware, software, and services for businesses and consumers.

- Hewlett Packard (HP): A multinational technology company that offers a wide range of hardware, software, and services for businesses and consumers

Case Studies of RFID Applications

Below are some RFID application cases in the hardware manufacturing industry:

Caterpillar began using RFID technology in its production to improve inventory management and reduce operational costs. The RFID system implemented by Caterpillar includes passive UHF RFID tags, readers, and software. Each part or component is tagged with a unique RFID tag, and readers are installed at various points in the production process to track the movement of the features. The data collected from the RFID system is then used to monitor inventory levels, track the location of features, and optimize production processes. Using RFID improves inventory accuracy, increased production efficiency, reduced labor costs, and improves supply chain visibility.

Honeywell began using RFID technology in its production to improve inventory management and reduce operational costs. The company implemented RFID in several of its factories across the U.S., including facilities that produce safety equipment and building automation systems. The RFID system implemented by Honeywell includes passive UHF RFID tags, readers, and software. Each part or component is tagged with a unique RFID tag, and readers are installed at various points in the production process to track the movement of the details. The data collected from the RFID system is then used to monitor inventory levels, track the location of parts, and optimize production processes. Using RFID improves inventory accuracy, increased production efficiency, reduced labor costs, and improves supply chain visibility.

Avery Dennison installed RFID readers and antennas throughout their facility and attached UHF RFID tags to their inventory of raw materials and finished products. The RFID system automatically tracked the movement of each item throughout the manufacturing process, allowing the company to gain real-time visibility into its inventory levels and production status. As a result of the RFID implementation, Avery Dennison was able to reduce their inventory holding costs by 30%, increase their production throughput by 10%, and improve their overall order fulfillment accuracy. The company also reported significant reductions in material waste and labor costs, as the RFID system eliminated the need for manual inventory tracking and reduced the likelihood of human error.

GAO RFID Systems & Hardware for the Hardware Manufacturing

GAO RFID Inc. offers the largest selection of BLE gateways, BLE beacons, RFID readers, tags, antennae, printers, and integrated RFID systems for various industries, including the hardware manufacturing industry.

BLE (Bluetooth Low Energy)

GAO offers advanced BLE gateways:

as well as versatile beacons with such important functions as temperature, humility, vibration and panic button:

GAO’s BLE technology is suitable for many industries, including the hardware manufacturing industry.

UHF (Ultra High Frequency) RFID

GAO offers the largest selection of UHF RFID readers for various industries, including the hardware manufacturing industry:

GAO RFID offers the widest choice of UHF RFID tags, labels, badges, wristbands for various industries, including the hardware manufacturing industry:

and an array of antennas to address different applications:

HF (High Frequency), NFC (Near Field Communications) and LF (Low Frequency) RFID

GAO offers the largest selection of HF, NFC, and LF RFID readers for various industries, including the hardware manufacturing industry:

- High Frequency 13.56 MHz Passive RFID Readers

- Low Frequency 134 kHz Passive RFID Readers

- Low Frequency 125 kHz Passive RFID Readers

HF, NFC and LF RFID tags, labels, badges, wristbands for various industries, including the hardware manufacturing industry:

and antennas:

GAO also offers RFID printers:

Digital I/O adapters:

and relay controllers:

For embedded applications, GAO offers UHF, HF and LF RFID reader modules:

- UHF 860 – 960 MHz RFID Modules

- 56 MHz High Frequency RFID Modules

- 125 kHz Low Frequency RFID Modules

The RFID systems by GAO are highly popular for clients in the hardware manufacturing industry:

Physical asset or operational equipment tracking system:

Assets that can be effectively tracked using GAO’s technologies include

- CNC Machines: Computer Numerical Control (CNC) machines are used for precision cutting, shaping, and drilling of various materials, including metal, plastic, and wood. They are commonly used in the manufacturing of components and parts for hardware products.

- 3D Printers: 3D printers are used to create three-dimensional objects by layering materials based on digital designs. They are increasingly utilized in hardware manufacturing for rapid prototyping, customization, and small-scale production.

- Injection Molding Machines: Injection molding machines are used to produce large quantities of plastic parts. Molten plastic is injected into a mold cavity under high pressure and cooled to form the desired shape. This process is commonly used in the production of casings and enclosures for hardware products.

- Surface Mount Technology (SMT) Machines: SMT machines are used in the assembly of electronic components onto printed circuit boards (PCBs). They accurately place surface-mounted components onto the PCBs, enabling efficient and automated production of electronic devices.

- Testing and Quality Control Equipment: This category includes various specialized equipment used to test and ensure the quality of hardware products. It may include equipment such as oscilloscopes, multimeters, environmental testing chambers, and vibration testing machines.

- Assembly and Packaging Equipment: Hardware products often require assembly and packaging processes. This equipment may include automated assembly lines, robotic arms, packaging machines, and labeling systems to streamline the manufacturing and packaging processes.

- Material Handling Equipment: Material handling equipment, such as conveyor systems, pallet jacks, and forklifts, is used to move materials, components, and finished products within the manufacturing facility.

- Welding and Joining Equipment: Welding machines and other joining equipment are used to fuse and connect metal components. Techniques such as arc welding, spot welding, and laser welding are employed to create strong and durable joints.

People or workers tracking system:

Personnel or people access control system:

Parking or vehicle control system:

GAO Has Served the Hardware Manufacturing Industry Extensively

GAO’s products and technologies have helped its customers in the hardware manufacturing industry to achieve success in Industry 4.0, Digital Transformation, Smart factories, the Internet of Things (IoT), Big data analytics, Artificial Intelligence (AI), and Machine Learning (ML), Additive manufacturing (3D printing), Robotics and Automation, Augmented Reality (AR) and Virtual Reality (VR), Cybersecurity and data privacy, Predictive maintenance, Edge computing, Digital twins, Cloud computing, and Sustainable manufacturing and circular economy.

GAO RFID Inc. has deployed RFID, BLE, and IoT projects for many companies in the hardware manufacturing industry, including many in its various divisions such as

- Electronic Components: Manufacturing of electronic parts, such as capacitors, resistors, and integrated circuits.

- Semiconductors: Designing and manufacturing semiconductors for electronic devices and other applications.

- Computer Hardware: Manufacturing of computer components and peripherals, including motherboards, hard drives, and printers.

- Networking and Communications Equipment: Production of equipment used for data transmission and telecommunications, including routers, switches, and modems.

- Consumer Electronics: Manufacturing of electronic products for personal and home use, including televisions, smartphones, and home appliances.

- Industrial Machinery: Production of machinery and equipment for industrial applications, such as factory automation and assembly line systems.

- Medical Devices: Manufacturing of equipment and devices used in healthcare, including diagnostic tools, prosthetics, and medical imaging equipment.

- Aerospace and Defense: Production of equipment and technology used in the aerospace and defense industries, such as aircraft engines, missiles, and satellites.

- Automotive: Manufacturing of automotive parts and components, including engines, transmissions, and braking systems.

- Heavy Equipment: Production of large machinery and vehicles used in construction, mining, and other heavy industries.

Here are some of the leading companies in the hardware manufacturingindustry: